Методи корегування поточних значень технологічних параметрів в автоматизованих системах керування

DOI:

https://doi.org/10.31498/2225-6733.51.2025.344904Ключові слова:

АСКТП, об’єкт керування, ідентифікація, мікроконтролер, підсистема введення технологічної інформаціїАнотація

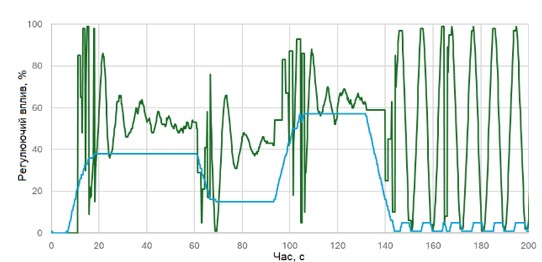

Розглядається питання організації збору та обробки технологічної інформації в АСУ ТП в рамках функціонування інформаційної підсистеми АСУ ТП. Висвітлено основні проблеми, що виникають при розробці програмного забезпечення. Поставлені основні задачі дослідження, описані методи вирішення проблеми, проведено експерименти з вимірювання технологічних параметрів (температура, швидкість повітря) при різних значеннях керуючих впливів. Обрано та розроблено алгоритми фільтрації та корекції аналогових сигналів. Проведено ідентифікацію параметрів об’єкта за отриманими експериментальними даними, розроблено та протестовано декілька систем автоматичного керування, проаналізовано результати моделювання роботи САР та порівняно з реальними вимірами

Посилання

Дорошенко В. С. Топологічна оптимізація конструкцій виливків при адитивному виробництві з застосуванням цифрового двійника. Процеси лиття. 2020. № 4 (142). С. 53-62. DOI: https://doi.org/10.15407/plit2020.04.053.

Гриценко В., Скурихін В., Цепков Г. Інформаційні технології цифрової обробки сигналів: нові підходи і перспективи впровадження. Вісник Національної академії наук України. 2005. № 12. С. 33-41.

Негоденко О. В. Моделі для обробки інформаційних сигналів на основі тригонометричних сплайнів. Зв'язок. 2018. № 4. С. 47-50.

Алдохін М. Д. Логічний аналізатор сигналів на ПЛІС. Електронна та акустична інженерія. 2020. Т. 3. № 4. С. 38-43. DOI: https://doi.org/10.20535/2617-0965.2020.3.4.199926.

Рязанцев О. І., Кардашук В. С., Рязанцев А. О. Дослідження впливу параметра фільтра на якість аналого-цифрового перетворення сигналу. Вісник Східноукраїнського національного університету імені Володимира Даля. 2020. № 7 (263). С. 29-34. DOI: https://doi.org/10.33216/1998-7927-2020-263-7-29-34.

Digital Estimation and Compensation of Analog Errors in Frequency-Interleaved ADCs / J. Song et al. Journal of Circuits, Systems and Computers. 2019. Vol. 28. Pp. 35-42. DOI: https://doi.org/10.1142/S0218126619501342.

Characterising the Digital Twin: A systematic literature review / D. Jones et al. CIRP Journal of Manufacturing Science and Technology. 2020. Vol. 29, part A. Pp. 36-52. DOI: https://doi.org/10.1016/j.cirpj.2020.02.002.

Digital Twin in Industry: State-of-the-Art / Tao F., Zhang H., Liu A., Nee A. Y. C. IEEE Transactions on Industrial Informatics. 2019. Vol. 15, iss. 4. Pp. 2405-2415. DOI: https://doi.org/10.1109/TII.2018.2873186.

Digital-Twin-Based Coordinated Optimal Control for Steel Continuous Casting Process / Yang J., Ji Z., Liu W., Xie Z. Metals. 2023. Vol. 13(4). Article 816. Pp. 123-143. DOI: https://doi.org/10.3390/met13040816.

Kanokogi H. AI in the Process Industry. Yokogawa Technical Report (Engl. Ed.). 2021. Vol. 64, no. 1. Pp. 53-60.

Smith J. L. Advances in neural networks and potential for their application to steel metallurgy. Materials Science and Technology. 2020. Vol. 36, iss. 17. DOI: https://doi.org/10.1080/02670836.2020.1839206.

Шилов Д., Ямненко Ю. Система дистанційного моніторингу ваги для бджільництва. Мікросистеми, електроніка та акустика. 2022. Т. 27, № 3. С. 267186–1 – 267186–7. DOI: https://doi.org/10.20535/2523-4455.mea.267186.

Койфман О., Мірошниченко В., Сімкін О. Аналітичне дослідження методів ідентифікації об’єкта керування. MiningMetalTech 2023 – The Mining and Metals Sector: Integration of Business, Technology and Education: Scientific monograph. Riga, Latvia: Baltija Publishing, 2023. С. 113-147. DOI: https://doi.org/10.30525/978-9934-26-382-8-7.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Журнал "Вісник Приазовського державного технічного університету. Серія: Технічні науки" видається під ліцензією СС-BY (Ліцензія «Із зазначенням авторства»).

Дана ліцензія дозволяє поширювати, редагувати, поправляти і брати твір за основу для похідних навіть на комерційній основі із зазначенням авторства. Це найзручніша з усіх пропонованих ліцензій. Рекомендується для максимального поширення і використання неліцензійних матеріалів.

Автори, які публікуються в цьому журналі, погоджуються з наступними умовами:

1. Автори залишають за собою право на авторство своєї роботи та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons Attribution License, яка дозволяє іншим особам вільно розповсюджувати опубліковану роботу з обов'язковим посиланням на авторів оригінальної роботи та першу публікацію роботи в цьому журналі.

2. Автори мають право укладати самостійні додаткові угоди, які стосуються неексклюзивного поширення роботи в тому вигляді, в якому вона була опублікована цим журналом (наприклад, розміщувати роботу в електронному сховищі установи або публікувати у складі монографії), за умови збереження посилання на першу публікацію роботи в цьому журналі.