Технології автоматизації в обслуговуванні суднових систем: проблеми та шляхи покращення через міжгалузевий досвід

DOI:

https://doi.org/10.31498/2225-6733.51.2025.344906Ключові слова:

морська індустрія, автоматизація, міжгалузевий досвід, прогнозне обслуговування, обслуговування за станом, дистанційний моніторинг, штучний інтелект, надійністьАнотація

Розглянуто міжгалузеве запозичення передових технологій автоматизації з авіаційної, залізничної, автомобільної, енергетичної, аерокосмічної та логістичної сфер для підвищення надійності, безпеки та ефективності технічного обслуговування морського транспорту. Зроблено акцент на важливості переходу від традиційного регламентного обслуговування до підходів, що базуються на фактичному технічному стані та прогнозуванні відмов. На основі аналізу сучасних рішень в інших галузях, розглянуто можливості адаптації таких інновацій у морській індустрії: впровадження дистанційного моніторингу обладнання, цифрових двійників, IoT (інтернет речей)-сенсорів, систем діагностики та машинного навчання для аналізу технічного стану, використання дронів та автономних роботів для інспекції та аварійних робіт, а також розробка комплексних цифрових платформ управління технічним обслуговуванням. Стаття демонструє, що такі технології вже довели свою ефективність у суміжних секторах – зниження кількості аварій на 30–70%, зменшення витрат на ремонти до 40%, скорочення простоїв на 20–50%. Водночас у морській галузі ці підходи все ще впроваджуються повільно, що зумовлено нестачею відкритих баз для навчання моделей прогнозування та відсутністю єдиних стандартів обміну технічною інформацією. Підкреслено необхідність системного підходу до інтеграції прогнозного обслуговування у морський транспорт, створення нормативної бази, розвитку цифрової інфраструктури флоту, підготовки персоналу до роботи з новими інструментами моніторингу й аналізу. У роботі наведено приклади вже реалізованих ініціатив: дистанційний моніторинг суднових енергетичних установок, використання сертифікованих дронів для інспекції танків, аналітичні платформи управління обслуговуванням флоту, а також описано потенційні майбутні розробки – дрони-ремонтники, автономні модулі пожежогасіння, цифрові паспорти “здоров’я” суден. Результати дослідження свідчать, що саме впровадження прогнозного обслуговування може стати ключовим напрямом цифрової трансформації морської індустрії. Це дозволить не лише підвищити безвідмовність суден і безпеку екіпажів, але й суттєво знизити експлуатаційні витрати, мінімізувати екологічні ризики та забезпечити вищий рівень готовності флоту до сучасних викликів

Посилання

Towards Predictive Maintenance in the Maritime Industry: A Component-Based Overview / A. S. Kalafatelis et al. Journal of Marine Science and Engineering, 2025. Vol. 13, no. 3. Article 425. DOI: https://doi.org/10.3390/jmse13030425.

Adortech Technical Blog. Minimizing railway downtime with predictive maintenance in railway. URL: https://adortech.com/blog/minimizing-railway-downtime-with-predictive-maintenance-in-railway (дата звернення: 15.09.2025).

Canaday H. What’s holding back predictive maintenance? Aviation Week Network. URL: https://aviationweek.com/mro/whats-holding-back-predictive-maintenance (дата звернення: 15.09.2025).

Zhong Hong. Predictive Maintenance in Manufac-turing: Reducing Downtime and Costs with AI. URL: https://medium.com/@zhonghong9998/predictive-maintenance-in-manufacturing-reducing-downtime-and-costs-with-ai-3374290c1388 (дата звернення: 15.09.2025).

Low A. K. J., Sim K. S., Lew K. L. Review on Automated Storage and Retrieval System for Ware-house. Journal of Informatics and Web Engineering. 2024. Vol. 3, no. 3. Pp. 77-97, DOI: https://doi.org/10.33093/jiwe.2024.3.3.5.

Sheng S. Wind Turbine Gearbox Condition Moni-toring Vibration Analysis Benchmarking Datasets. Data set. Open Energy Data Initiative (OEDI). National Renewable Energy Laboratory, 2014. DOI: https://doi.org/10.25984/1844194.

Renewable Energy World. Smart monitoring is the key to unlocking more value from wind energy, URL: https://www.renewableenergyworld.com/wind-power/turbines-equipment/smart-monitoring-is-the-key-to-unlocking-more-value-from-wind-energy/ (дата звернення: 15.09.2025).

Svilicic B., Rudan I., Jugović A., Zec D. A Study on Cyber Security Threats in a Shipboard Integrated Navigational System. Journal of Marine Science and Engineering. 2019. Vol. 7, no. 10. Article 364. DOI: https://doi.org/10.3390/jmse7100364.

Riviera Maritime Media. Remote monitoring moves to the mainstream. URL: https://www.rivieramm.com/opinion/opinion/remote-monitoring-moves-to-the-mainstream-36670 (дата звернення: 15.09.2025).

Annual Review 2025. International Air Transport Association. 2025. 59 p. URL: https://www.iata.org/contentassets/c81222d96c9a4e0bb4ff6ced0126f0bb/iata-annual-review-2025.pdf (дата звернення: 15.09.2025).

Predictive maintenance of rail infrastructure. URL: https://www.brunel.ac.uk/research/projects/predictive-maintenance-of-rail-infrastructure (дата звернення: 15.09.2025).

Kidd D. G. Improving the safety relevance of automatic emergency braking testing programs: An examination of common characteristics of police-reported rear-end crashes in the United States. Traffic Injury Prevention. 2022. Vol. 23, no. sup1. DOI: https://doi.org/10.1080/15389588.2022.2090544.

Safety of nuclear power plants: Commissioning and operation: specific safety requirements. Vienna: International Atomic Energy Agency, 2011. 55 p.

World Nuclear Association. Safety of nuclear power reactors. URL: https://world-nuclear.org/information-library/safety-and-security/safety-of-plants/safety-of-nuclear-power-reactors (дата звернення: 15.09.2025).

Nuclear power is the most reliable energy source and it’s not even close. URL: https://www.energy.gov/ne/articles/nuclear-power-most-reliable-energy-source-and-its-not-even-close (дата звернення: 15.09.2025).

Proven Advanced Predictive Maintenance for Energy & Utilities, Number Analytics. URL: https://www.numberanalytics.com/blog/proven-advanced-predictive-maintenance-energy-utilities (дата звернення: 15.09.2025).

Sustainable LLM Inference for Edge AI: Evaluating Quantized LLMs for Energy Efficiency, Output Accuracy, and Inference Latency / E. J. Husom et al. ACM Transactions on Internet of Things. 2025. Pp. 1-34. DOI: https://doi.org/10.1145/3767742.

Jalilian S., SalarKaleji F., Kazimov T. Fault detec-tion, isolation and recovery (FDIR) in satellite onboard software. Proqram mühəndisliyinin aktual elmi-praktiki problemləri I respublika konfransının materialları, Bakı, Azərbaycan, 17 May 2017. Pp. 329-332. DOI: https://doi.org/10.25045/ncsofteng.2017.87.

Menon A. Automation and robotics in space, Blue Marble Space Institute of Science. URL: https://bmsis.org/automation-and-robotics-in-space (дата звернення: 15.09.2025).

Lee S. The predictive Maintenance Impact on Aerospace&Defense. URL: https://www.numberanalytics.com/blog/the-predictive-maintenance-impact (дата звернення: 15.09.2025).

Gokulakannan B., Danush B., Senthil Kumar J. Autonomous with GPS based controlled mobile robot for material handling in warehouse. Journal of Dynamics and Control. 2025. Vol. 9, no. 3. Pp. 60-69. DOI: https://doi.org/10.71058/jodac.v9i3004.

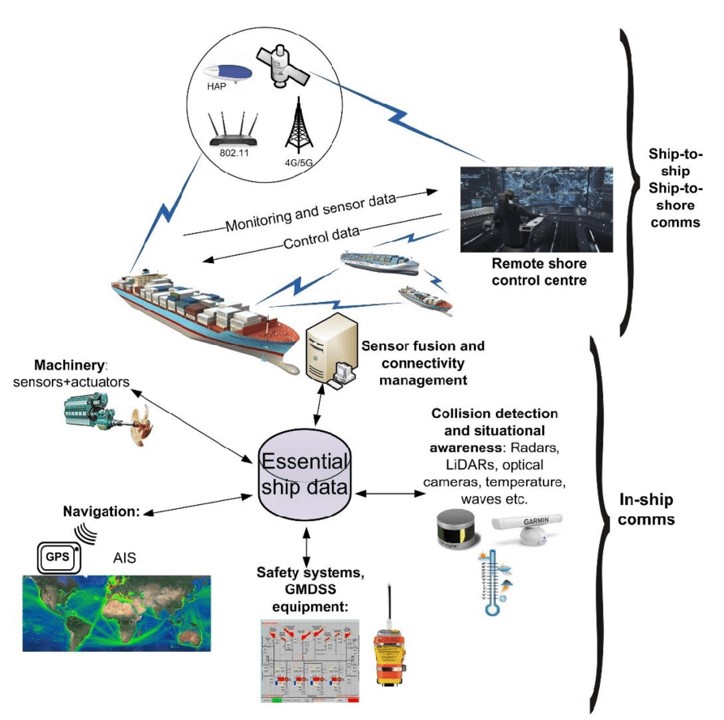

Connectivity for autonomous ships: Architecture, use cases, and research challenges / M. Hoyhtya et al. 2017 International Conference on Information and Communication Technology Convergence (ICTC), Jeju, Korea, 8-20 Oct. 2017. Pp. 345–350. DOI: https://doi.org/10.1109/ictc.2017.8191000.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Журнал "Вісник Приазовського державного технічного університету. Серія: Технічні науки" видається під ліцензією СС-BY (Ліцензія «Із зазначенням авторства»).

Дана ліцензія дозволяє поширювати, редагувати, поправляти і брати твір за основу для похідних навіть на комерційній основі із зазначенням авторства. Це найзручніша з усіх пропонованих ліцензій. Рекомендується для максимального поширення і використання неліцензійних матеріалів.

Автори, які публікуються в цьому журналі, погоджуються з наступними умовами:

1. Автори залишають за собою право на авторство своєї роботи та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons Attribution License, яка дозволяє іншим особам вільно розповсюджувати опубліковану роботу з обов'язковим посиланням на авторів оригінальної роботи та першу публікацію роботи в цьому журналі.

2. Автори мають право укладати самостійні додаткові угоди, які стосуються неексклюзивного поширення роботи в тому вигляді, в якому вона була опублікована цим журналом (наприклад, розміщувати роботу в електронному сховищі установи або публікувати у складі монографії), за умови збереження посилання на першу публікацію роботи в цьому журналі.