Development of a technology for the production of germinated flaxseed using plasma-chemically activated aqueous solutions

DOI:

https://doi.org/10.15587/1729-4061.2023.284810Keywords:

flaxseed, plasma-chemical activation, germination, germinated seeds, biologically active substancesAbstract

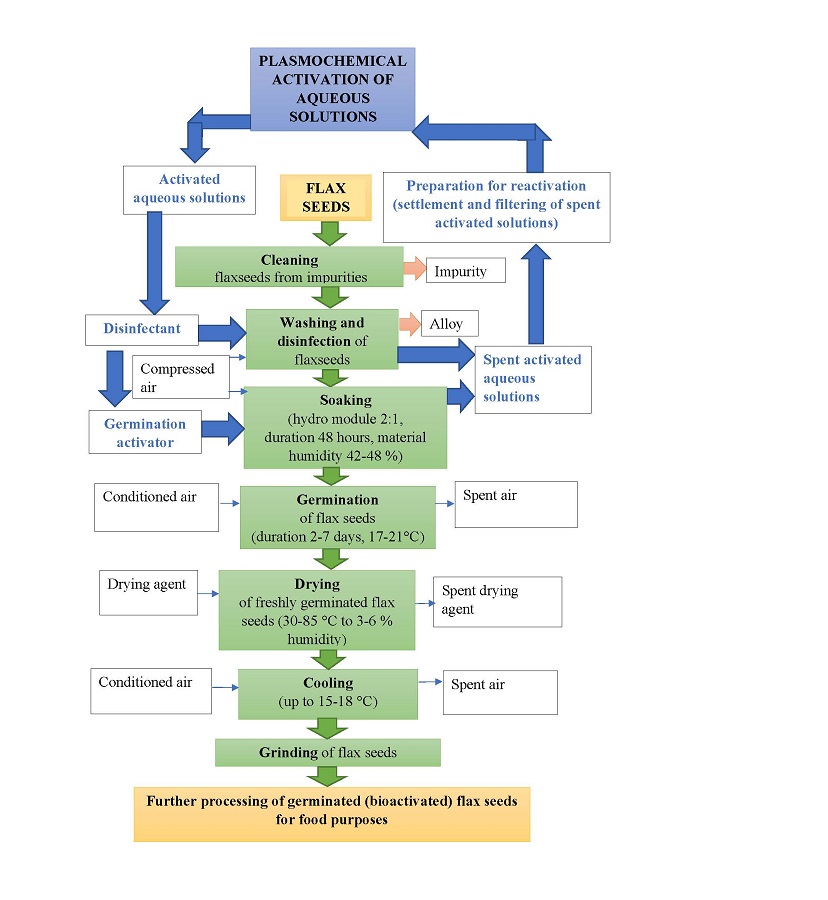

The result of the research is the development of a technology for the production of germinated flaxseed using plasma-chemically activated aqueous solutions. The object of research was flaxseed. An urgent technological problem is the intensification of the bioactivation process of flaxseed and its effective disinfection. The expediency of using plasma-chemically activated aqueous solutions as an intensifier of the process of flaxseed germination and an effective disinfectant of food raw materials was experimentally proven. It is shown that the use of plasma-chemical activation of process solutions not only accelerates flaxseed germination, but also contributes to a more active accumulation of biologically valuable components in flax raw materials. The composition of flaxseed as a raw material derivative was analyzed. Germinated flaxseed, which is considered a high-value component of food products, was studied separately. An increase in the moisture content of flaxseed during the soaking process by 0.7–1.7 % was recorded. Seedling development increases by 2–9 mm. The germination energy and capacity increase by 5–12 %. The biomass of germinated seeds increases by 39–56 %. In the process of germination, the content of proteins in flaxseed increases from 21.88 to 23.71 %, reducing sugars from 2.37 to 4.02 %. The total content of amino acids increases from 3.64 to 10.38 % compared to the control, and 10 times compared to the raw material. A significant accumulation of vitamins was noted: B1, B2, B3, B5, B6, B7, B9, C, E. In addition, plasma-chemically activated solutions effectively disinfect germinated flaxseed.

The technology can be applied in the production of enrichment components of food products. The developed technology will receive special attention in the production of functional food products

References

- Kraevska, S., Yeshchenko, O., Stetsenko, N. (2019). Optimization of the technological process of flax seed germination. Food Science and Technology, 13 (3). doi: https://doi.org/10.15673/fst.v13i3.1453

- Gutiérrez, C., Rubilar, M., Jara, C., Verdugo, M., Sineiro, J., Shene, C. (2010). Flaxseed and flaxseed cake as a source of compounds for food industry. Journal of Soil Science and Plant Nutrition, 10 (4), 454–463. doi: https://doi.org/10.4067/s0718-95162010000200006

- Sebei, K., Debez, A., Herchi, W., Boukhchina, S., Kallel, H. (2007). Germination kinetics and seed reserve mobilization in two flax (Linum usitatissimum L.) cultivars under moderate salt stress. Journal of Plant Biology, 50 (4), 447–454. doi: https://doi.org/10.1007/bf03030681

- Wang, H., Wang, J., Guo, X., Brennan, C. S., Li, T., Fu, X. et al. (2016). Effect of germination on lignan biosynthesis, and antioxidant and antiproliferative activities in flaxseed (Linum usitatissimum L.). Food Chemistry, 205, 170–177. doi: https://doi.org/10.1016/j.foodchem.2016.03.001

- Katare, C., Saxena, S., Agrawal, S., Prasad, G. (2012). Flax Seed: A Potential Medicinal Food. Journal of Nutrition & Food Sciences, 02 (01). doi: https://doi.org/10.4172/2155-9600.1000120

- Gutte, K. B., Sahoo, A. K., Ranveer, R. C. (2015). Bioactive Components of Flaxseed and its Health Benefits. International Journal of Pharmaceutical Sciences Review and Research, 31 (1), 42–51. Available at: https://www.researchgate.net/publication/273441906_Bioactive_Components_of_Flaxseed_and_its_Health_Benefits

- Kraevska, S., Stetsenko, N., Korol, O. (2017). Comparing Between The Amino Acid Composition Of Flax Seeds Before And After Germination. Agrobiodiversity for Improving Nutrition, Health and Life Quality, 253–257. doi: https://doi.org/10.15414/agrobiodiversity.2017.2585-8246.253-257

- Singh, K. K., Mridula, D., Rehal, J., Barnwal, P. (2011). Flaxseed: A Potential Source of Food, Feed and Fiber. Critical Reviews in Food Science and Nutrition, 51 (3), 210–222. doi: https://doi.org/10.1080/10408390903537241

- Edel, A. L., Aliani, M., Pierce, G. N. (2015). Stability of bioactives in flaxseed and flaxseed-fortified foods. Food Research International, 77, 140–155. doi: https://doi.org/10.1016/j.foodres.2015.07.035

- Ghosal, S., Bhattacharyya, D. K., Bhowal, J. (2022). Production, characterization, and storage stability of nutritionally enriched flaxseed‐based spread. Journal of Food Processing and Preservation, 46 (5). doi: https://doi.org/10.1111/jfpp.16574

- Goyal, A., Sharma, V., Upadhyay, N., Gill, S., Sihag, M. (2014). Flax and flaxseed oil: an ancient medicine & modern functional food. Journal of Food Science and Technology, 51 (9), 1633–1653. doi: https://doi.org/10.1007/s13197-013-1247-9

- Kovalova, O., Vasylieva, N., Stankevych, S., Zabrodina, I., Haliasnyi, I., Gontar, T. et al. (2023). Determining the effect of plasmochemically activated aqueous solutions on the bioactivation process of sea buckthorn seeds. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 99–111. doi: https://doi.org/10.15587/1729-4061.2023.275548

- Minevich, I. E., Nechiporenko, A. P., Goncharova, A. A., Sitnikova, V. E. (2021). Dynamics of macronutrients during short-term germination of flax seeds. Proceedings of Universities. Applied Chemistry and Biotechnology, 11 (3), 449–459. doi: https://doi.org/10.21285/2227-2925-2021-11-3-449-459

- Herchi, W., Bahashwan, S., Sebei, K., Ben Saleh, H., Kallel, H., Boukhchina, S. (2015). Effects of germination on chemical composition and antioxidant activity of flaxseed (Linum usitatissimum) oil. Grasas y Aceites, 66 (1), e057. doi: https://doi.org/10.3989/gya.0463141

- Villeneuve, S., Power, K. A., Guévremont, E., Mondor, M., Tsao, R., Wanasundara, J. P. D. et al. (2014). Effect of a Short-Time Germination Process on the Nutrient Composition, Microbial Counts and Bread-Making Potential of Whole Flaxseed. Journal of Food Processing and Preservation, 39 (6), 1574–1586. doi: https://doi.org/10.1111/jfpp.12385

- Wu, Y., Wang, H., Wang, Y., Brennan, C. S., Anne Brennan, M., Qiu, C., Guo, X. (2020). Comparison of lignans and phenolic acids in different varieties of germinated flaxseed (Linum usitatissimum L.). International Journal of Food Science & Technology, 56 (1), 196–204. doi: https://doi.org/10.1111/ijfs.14619

- Li, X., Li, J., Dong, S., Li, Y., Wei, L., Zhao, C. et al. (2019). Effects of germination on tocopherol, secoisolarlciresinol diglucoside, cyanogenic glycosides and antioxidant activities in flaxseed (Linum usitatissimumL.). International Journal of Food Science & Technology, 54 (7), 2346–2354. doi: https://doi.org/10.1111/ijfs.14098

- Kajla, P., Sharma, A., Sood, D. R. (2014). Flaxseed – a potential functional food source. Journal of Food Science and Technology, 52 (4), 1857–1871. doi: https://doi.org/10.1007/s13197-014-1293-y

- Liu, J., Shim, Y. Y., Tse, T. J., Wang, Y., Reaney, M. J. T. (2018). Flaxseed gum a versatile natural hydrocolloid for food and non-food applications. Trends in Food Science & Technology, 75, 146–157. doi: https://doi.org/10.1016/j.tifs.2018.01.011

- Bekhit, A. E.-D. A., Shavandi, A., Jodjaja, T., Birch, J., Teh, S., Mohamed Ahmed, I. A. et al. (2018). Flaxseed: Composition, detoxification, utilization, and opportunities. Biocatalysis and Agricultural Biotechnology, 13, 129–152. doi: https://doi.org/10.1016/j.bcab.2017.11.017

- Kurt, O. (2012). A predictive model for the effects of temperature on the germination period of flax seeds (Linum usitatissimum L.). Turkish Journal of Agriculture and Forestry, 36 (6), 654–658. doi: https://doi.org/10.3906/tar-1202-13

- Bayat, M., Zargar, M., Murtazova, K. M.-S., Nakhaev, M. R., Shkurkin, S. I. (2022). Ameliorating Seed Germination and Seedling Growth of Nano-Primed Wheat and Flax Seeds Using Seven Biogenic Metal-Based Nanoparticles. Agronomy, 12 (4), 811. doi: https://doi.org/10.3390/agronomy12040811

- Kovaliova, O., Chursinov, Y., Kalyna, V., Khromenko, T., Kunitsia, E. (2020). Investigation of the intensive technology of food sprouts using organic acids. EUREKA: Life Sciences, 2, 45–53. doi: https://doi.org/10.21303/2504-5695.2020.001204

- Pivovarov, O., Kovaliova, O. (2019). Features of grain germination with the use of aqueous solutions of fruit acids. Food Science and Technology, 13 (1). doi: https://doi.org/10.15673/fst.v13i1.1334

- Kovaliova, O., Tchoursinov, Y., Kalyna, V., Koshulko, V., Kunitsia, E., Chernukha, A. et al. (2020). Identification of patterns in the production of a biologically-active component for food products. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 61–68. doi: https://doi.org/10.15587/1729-4061.2020.200026

- Pivovarov, O., Kovaliova, O., Koshulko, V. (2020). Effect of plasmochemically activated aqueous solution on process of food sprouts production. Ukrainian Food Journal, 9 (3), 576–587. doi: https://doi.org/10.24263/2304-974x-2020-9-3-7

- Kovaliova, O., Pivovarov, O., Koshulko, V. (2020). Study of hydrothermal treatment of dried malt with plasmochemically activated aqueous solutions. Food Science and Technology, 14 (3). doi: https://doi.org/10.15673/fst.v14i3.1799

- Pivovarov, O., Kovaliova, O., Khromenko, T., Shuliakevych, Z. (2017). Features of obtaining malt with use of aqueous solutions of organic acids. Food Science and Technology, 11 (4). doi: https://doi.org/10.15673/fst.v11i4.728

- Fang, Y., Franke, C., Manthei, A., McMullen, L., Temelli, F., Gänzle, M. G. (2021). Effects of high-pressure carbon dioxide on microbial quality and germination of cereal grains and beans. The Journal of Supercritical Fluids, 175, 105272. doi: https://doi.org/10.1016/j.supflu.2021.105272

- Zhao, Y., Patange, A., Sun, D., Tiwari, B. (2020). Plasma‐activated water: Physicochemical properties, microbial inactivation mechanisms, factors influencing antimicrobial effectiveness, and applications in the food industry. Comprehensive Reviews in Food Science and Food Safety, 19 (6), 3951–3979. doi: https://doi.org/10.1111/1541-4337.12644

- Bourke, P., Ziuzina, D., Boehm, D., Cullen, P. J., Keener, K. (2018). The Potential of Cold Plasma for Safe and Sustainable Food Production. Trends in Biotechnology, 36 (6), 615–626. doi: https://doi.org/10.1016/j.tibtech.2017.11.001

- Lin, C.-M., Chu, Y.-C., Hsiao, C.-P., Wu, J.-S., Hsieh, C.-W., Hou, C.-Y. (2019). The Optimization of Plasma-Activated Water Treatments to Inactivate Salmonella Enteritidis (ATCC 13076) on Shell Eggs. Foods, 8 (10), 520. doi: https://doi.org/10.3390/foods8100520

- Pivovarov, O. A., Kovaleva, O. S., Chursinov, J. O. (2020). Prevention of biofouling of industrial reverse water supply systems by plasma water treatment. 3 nd International Scientific and Technical Internet Conference “Innovative development of resource-saving technologies and sustainable use of natural resources”. Petroșani: UNIVERSITAS Publishing, 50–52. Available at: https://dspace.dsau.dp.ua/handle/123456789/5295

- Pivovarov, О., Kovalova, О., Koshulko, V., Aleksandrova, A. (2022). Study of use of antiseptic ice of plasma-chemically activated aqueous solutions for the storage of food raw materials. Food Science and Technology, 15 (4). doi: https://doi.org/10.15673/fst.v15i4.2260

- Kovaliova, O., Pivovarov, O., Kalyna, V., Tchoursinov, Y., Kunitsia, E., Chernukha, A. et al. (2020). Implementation of the plasmochemical activation of technological solutions in the process of ecologization of malt production. Eastern-European Journal of Enterprise Technologies, 5 (10 (107)), 26–35. doi: https://doi.org/10.15587/1729-4061.2020.215160

- Pivovarov, О., Kovaliova, О., Koshulko, V. (2022). Effect of plasma-chemically activated aqueous solutions on the process of disinfection of food production equipment. Food Science and Technology, 16 (3). doi: https://doi.org/10.15673/fst.v16i3.2392

- Greene, W. (2017). Econometric Analysis. London: Pearson Learning Solutions, 1176.

- Wooldridge, J. M. (2012). Introductory Econometrics: A Modern Approach. Boston, MA: Cengage Learning, 910.

- Erkmen, O. (2022). Microbiological analysis of foods and food processing environments. Academic Press. doi: https://doi.org/10.1016/c2021-0-01219-0

- Vasylieva, N. (2013). Forecasting of prices in the field of crops-growing in Ukraine and regions. Economic Annals-XXI, 11-12 (2), 26–29. Available at: http://ea21journal.world/index.php/ea-v136-07/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Olena Kovaliova, Natalia Vasylieva, Serhii Stankevych, Inna Zabrodina, Oleksandra Mandych, Tatyana Hontar, Ivan Haliasnyi, Oleh Kotliar, Oleksandr Yanchyk, Oleg Bogatov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.