Determining the effect of raw materials moisture and lipid content on the technological properties of the extruded protein-fat system

DOI:

https://doi.org/10.15587/1729-4061.2023.285132Keywords:

extrusion, protein-fat system, meal, corn grits, moisture content, lipid content, porosityAbstract

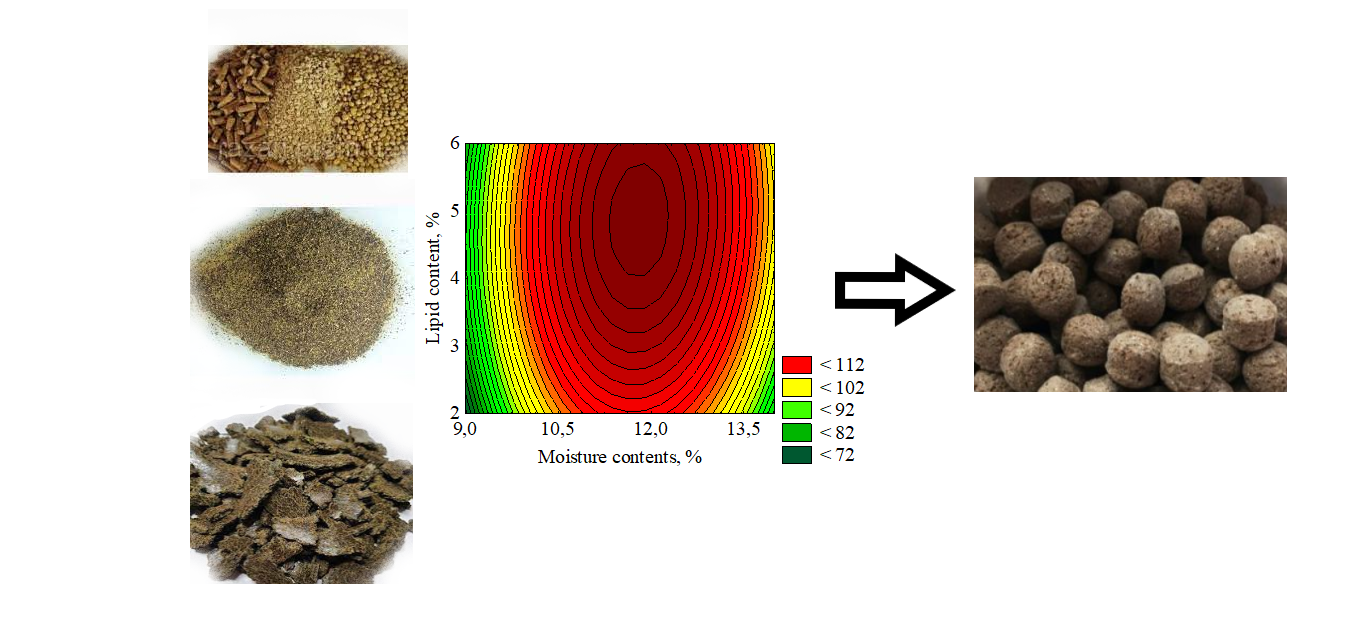

The way to solve the problem of correcting technological indicators, in particular porosity and moisture content, in extruded protein-fat systems based on soybean, rapeseed, hemp meal, and corn grits is considered. The peculiarity of the work is the substantiation of the rational ratio of the content of moisture and lipids in the raw components of the extrudate, which is an important aspect of rationalizing the composition and improving the texture of innovative extruded products based on the specified raw materials.

The object of the research is technological indicators, in particular the porosity and moisture content of the extruded protein-fat system, depending on the moisture and lipid content in the raw components. A rational ratio of moisture content (10.5...12.5 %) and lipids (3.5...5.0 %) in the raw material for the extruded protein-fat system was determined. The use of refined palm olein as an oil product resistant to oxidative deterioration, which should be added to raw components in order to correct the technological properties of the finished product, is substantiated.

The developed protein-fat system of reasonable composition has an advantage over a commercial similar product in terms of crude protein content (29.0 % vs. 8.2 %), porosity (130.0 % vs. 105.0 %) and cost ($ 916/t vs. $ 2,798/t). The obtained data are explained by the fact that a complex of components was used, some of which are production waste, with reasonable moisture and lipid content, which improved the technological characteristics of the extrudate. An applied aspect of using this scientific result is the possibility of rationalizing the extrusion process of oilseed meal to achieve the desired texture, porosity and stability of the lipid component of the product

References

- Sokolov, V. M., Gorbenko, V. V., Vinnik, I. A., Mekhed, O. M. (2006). Processing the Ni- And Cr-bearing oxidized scarfing granulates with liquid cast iron. Extraction and Processing Division: Sohn International Symposium, 1, 453–462.

- Danchenko, Y., Andronov, V., Barabash, E., Obigenko, T., Rybka, E., Meleshchenko, R., Romin, A. (2017). Research of the intramolecular interactions and structure in epoxyamine composites with dispersed oxides. Eastern-European Journal of Enterprise Technologies, 6 (12 (90)), 4–12. doi: https://doi.org/10.15587/1729-4061.2017.118565

- Vambol, S., Bogdanov, I., Vambol, V., Suchikova, Y., Lopatina, H., Tsybuliak, N. (2017). Research into effect of electrochemical etching conditions on the morphology of porous gallium arsenide. Eastern-European Journal of Enterprise Technologies, 6 (5 (90)), 22–31. doi: https://doi.org/10.15587/1729-4061.2017.118725

- Vambol, S., Vambol, V., Kondratenko, O., Koloskov, V., Suchikova, Y. (2018). Substantiation of expedience of application of high-temperature utilization of used tires for liquefied methane production. Journal of Achievements in Materials and Manufacturing Engineering, 87 (2), 77–84. doi: https://doi.org/10.5604/01.3001.0012.2830

- Kovaliova, O., Tchoursinov, Y., Kalyna, V., Koshulko, V., Kunitsia, E., Chernukha, A. et al. (2020). Identification of patterns in the production of a biologically-active component for food products. Eastern-European Journal of Enterprise Technologies, 2 (11 (104)), 61–68. doi: https://doi.org/10.15587/1729-4061.2020.200026

- Loboichenko, V. M., Vasyukov, A. E., Tishakova, T. S. (2017). Investigations of Mineralization of Water Bodies on the Example of River Waters of Ukraine. Asian Journal of Water, Environment and Pollution, 14 (4), 37–41. doi: https://doi.org/10.3233/ajw-170035

- Sadkovyi, V., Pospelov, B., Andronov, V., Rybka, E., Krainiukov, O., Rud, A. et al. (2020). Construction of a method for detecting arbitrary hazard pollutants in the atmospheric air based on the structural function of the current pollutant concentrations. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 14–22. doi: https://doi.org/10.15587/1729-4061.2020.218714

- Pospelov, B., Andronov, V., Rybka, E., Krainiukov, O., Maksymenko, N., Meleshchenko, R. et al. (2020). Mathematical model of determining a risk to the human health along with the detection of hazardous states of urban atmosphere pollution based on measuring the current concentrations of pollutants. Eastern-European Journal of Enterprise Technologies, 4 (10 (106)), 37–44. doi: https://doi.org/10.15587/1729-4061.2020.210059

- Vambol, S., Vambol, V., Sychikova, Y., Deyneko, N. (2017). Analysis of the ways to provide ecological safety for the products of nanotechnologies throughout their life cycle. Eastern-European Journal of Enterprise Technologies, 1 (10 (85)), 27–36. doi: https://doi.org/10.15587/1729-4061.2017.85847

- Vambol, S., Bogdanov, I., Vambol, V., Suchikova, Y., Kondratenko, O., Hurenko, O., Onishchenko, S. (2017). Research into regularities of pore formation on the surface of semiconductors. Eastern-European Journal of Enterprise Technologies, 3 (5 (87)), 37–44. doi: https://doi.org/10.15587/1729-4061.2017.104039

- Petik, I., Litvinenko, O., Kalyna, V., Ilinska, O., Raiko, V., Filenko, O. et al. (2023). Development of extruded animal feed based on fat and oil industry waste. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 112–120. doi: https://doi.org/10.15587/1729-4061.2023.275509

- Wallace, T., Gibbons, D., O’Dwyer, M., Curran, T. P. (2017). International evolution of fat, oil and grease (FOG) waste management – A review. Journal of Environmental Management, 187, 424–435. doi: https://doi.org/10.1016/j.jenvman.2016.11.003

- Tsykhanovska, I., Evlash, V., Alexandrov, A., Lazarieva, T., Svidlo, K., Gontar, T. et al. (2018). Substantiation of the mechanism of interaction between biopolymers of ryeandwheat flour and the nanoparticles of the magnetofооd food additive in order to improve moistureretaining capacity of dough. Eastern-European Journal of Enterprise Technologies, 2 (11 (92)), 70–80. doi: https://doi.org/10.15587/1729-4061.2018.126358

- Danchenko, Y., Andronov, V., Kariev, A., Lebedev, V., Rybka, E., Meleshchenko, R., Yavorska, D. (2017). Research into surface properties of disperse fillers based on plant raw materials. Eastern-European Journal of Enterprise Technologies, 5 (12 (89)), 20–26. doi: https://doi.org/10.15587/1729-4061.2017.111350

- Petik, I., Belinska, A., Kunitsia, E., Bochkarev, S., Ovsiannikova, T., Kalyna, V. et al. (2021). Processing of ethanol-containing waste of oil neutralization in the technology of hand cleaning paste. Eastern-European Journal of Enterprise Technologies, 1 (10 (109)), 23–29. doi: https://doi.org/10.15587/1729-4061.2021.225233

- Singh, S., Gamlath, S., Wakeling, L. (2007). Nutritional aspects of food extrusion: a review. International Journal of Food Science & Technology, 42 (8), 916–929. doi: https://doi.org/10.1111/j.1365-2621.2006.01309.x

- Papchenko, V., Matveeva, T., Bochkarev, S., Belinska, A., Kunitsia, E., Chernukha, A. et al. (2020). Development of amino acid balanced food systems based on wheat flour and oilseed meal. Eastern-European Journal of Enterprise Technologies, 3 (11 (105)), 66–76. doi: https://doi.org/10.15587/1729-4061.2020.203664

- Sentís-Moré, P., Ortega-Olivé, N., Mas-Capdevila, A., Romero-Fabregat, M.-P. (2022). Impact of centrifugation and vacuum filtration step on the yield and molecular weight distribution of protein hydrolysates from rapeseed and sunflower meals. LWT, 165, 113741. doi: https://doi.org/10.1016/j.lwt.2022.113741

- Malomo, S. A., Aluko, R. E. (2015). Conversion of a low protein hemp seed meal into a functional protein concentrate through enzymatic digestion of fibre coupled with membrane ultrafiltration. Innovative Food Science & Emerging Technologies, 31, 151–159. doi: https://doi.org/10.1016/j.ifset.2015.08.004

- Kamali Rousta, L., Bodbodak, S., Nejatian, M., Ghandehari Yazdi, A. P., Rafiee, Z., Xiao, J., Jafari, S. M. (2021). Use of encapsulation technology to enrich and fortify bakery, pasta, and cereal-based products. Trends in Food Science & Technology, 118, 688–710. doi: https://doi.org/10.1016/j.tifs.2021.10.029

- Singh, J. P., Kaur, A., Singh, B., Singh, N., Singh, B. (2019). Physicochemical evaluation of corn extrudates containing varying buckwheat flour levels prepared at various extrusion temperatures. Journal of Food Science and Technology, 56 (4), 2205–2212. doi: https://doi.org/10.1007/s13197-019-03703-y

- Mazaheri Tehrani, M., Ehtiati, A., Sharifi Azghandi, S. (2017). Application of genetic algorithm to optimize extrusion condition for soy-based meat analogue texturization. Journal of Food Science and Technology, 54 (5), 1119–1125. doi: https://doi.org/10.1007/s13197-017-2524-9

- Zhang, B., Liu, G., Ying, D., Sanguansri, L., Augustin, M. A. (2017). Effect of extrusion conditions on the physico-chemical properties and in vitro protein digestibility of canola meal. Food Research International, 100, 658–664. doi: https://doi.org/10.1016/j.foodres.2017.07.060

- Mridula, D., Sethi, S., Tushir, S., Bhadwal, S., Gupta, R. K., Nanda, S. K. (2017). Co-extrusion of food grains-banana pulp for nutritious snacks: optimization of process variables. Journal of Food Science and Technology, 54 (9), 2704–2716. doi: https://doi.org/10.1007/s13197-017-2707-4

- Saldanha do Carmo, C., Varela, P., Poudroux, C., Dessev, T., Myhrer, K., Rieder, A. et al. (2019). The impact of extrusion parameters on physicochemical, nutritional and sensorial properties of expanded snacks from pea and oat fractions. LWT, 112, 108252. doi: https://doi.org/10.1016/j.lwt.2019.108252

- Zahari, I., Purhagen, J. K., Rayner, M., Ahlström, C., Helstad, A., Landers, M. et al. (2023). Extrusion of high-moisture meat analogues from hempseed protein concentrate and oat fibre residue. Journal of Food Engineering, 354, 111567. doi: https://doi.org/10.1016/j.jfoodeng.2023.111567

- Delgado, E., Valles-Rosales, D. J., Flores, N. C., Reyes-Jáquez, D. (2021). Evaluation of fish oil content and cottonseed meal with ultralow gossypol content on the functional properties of an extruded shrimp feed. Aquaculture Reports, 19, 100588. doi: https://doi.org/10.1016/j.aqrep.2021.100588

- Rashid, M. T., Liu, K., Han, S., Jatoi, M. A., Sarpong, F. (2023). Optimization of Extrusion Treatments, Quality Assessments, and Kinetics Degradation of Enzyme Activities during Storage of Rice Bran. Foods, 12 (6), 1236. doi: https://doi.org/10.3390/foods12061236

- Plastivtsi ekstrudovani multyzlakovi «Molodist». Available at: https://prom.ua/ua/p1521753798-hlopya-ekstrudirovannye-multizlakovye.html

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Victoriіa Papchenko, Galyna Stepankova, Olena Karatieieva, Iryna Balandina, Denys Shapovalenko, Andrii Kariuk, Yevhenii Statyvka, Olha Bakumenko, Andrii Melnyk, Serhii Нorbas

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.