Evaluation of a biomass combustion furnace using different kinds of combustion chamber casing materials

DOI:

https://doi.org/10.15587/1729-4061.2023.288834Keywords:

coconut shell briquettes, cylindrical shapes, household briquette stoves, thermal characteristicsAbstract

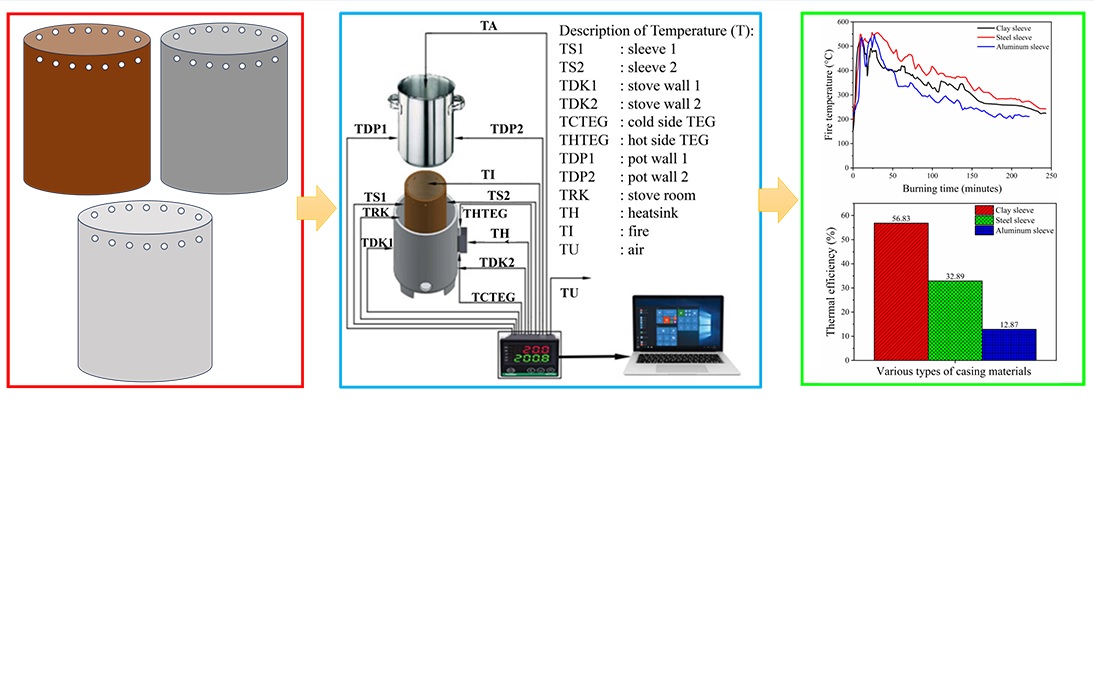

This research systematically evaluates a biomass combustion furnace, focusing on the influence of varying combustion chamber casing materials. The study employs controlled laboratory experiments to investigate the impact of different casing materials on combustion performance, thermal efficiency, and practical applications such as water boiling capacity. The research uses distinct materials, including clay, steel, and aluminum, for combustion chamber casings while maintaining consistent dimensions. The central experimental apparatus, an aluminum stove, was meticulously crafted, adhering to precise measurements. Coconut shell briquettes served as the primary fuel source for this investigation. The results reveal intriguing dynamics in combustion behavior. Notably, the choice of combustion chamber casing material significantly affects fire temperature, sleeve wall temperature, thermal efficiency, and the ability to boil water. Clay emerges as a standout performer, achieving high thermal efficiency (56.8 %), substantial water boiling capacity (25 liters), and efficient fuel consumption (1.28 kg of burnt briquettes). However, steel casing materials excel in generating the highest fire temperatures (up to 557 °C), underscoring their exceptional heat-conducting properties. Aluminum has fast temperature responses but may not retain heat like clay. The findings help optimize biomass combustion furnaces and associated applications. Material selection is crucial to attaining combustion goals like efficiency, temperature generation, or practical heat. These discoveries could lead to more efficient and ecologically friendly biomass combustion systems for sustainable energy and resource use

References

- Njenga, M., Karanja, N., Karlsson, H., Jamnadass, R., Iiyama, M., Kithinji, J., Sundberg, C. (2014). Additional cooking fuel supply and reduced global warming potential from recycling charcoal dust into charcoal briquette in Kenya. Journal of Cleaner Production, 81, 81–88. doi: https://doi.org/10.1016/j.jclepro.2014.06.002

- Yuliah, Y., Kartawidjaja, M., Suryaningsih, S., Ulfi, K. (2017). Fabrication and characterization of rice husk and coconut shell charcoal based bio-briquettes as alternative energy source. IOP Conference Series: Earth and Environmental Science, 65, 012021. doi: https://doi.org/10.1088/1755-1315/65/1/012021

- Amoako, G., Mensah-Amoah, P. (2018). Determination of calorific values of coconut shells and coconut husks. Journal of Materials Science Research and Reviews, 2 (2). Available at: https://ir.ucc.edu.gh/xmlui/handle/123456789/6153

- Lukas, A. G., Lombok, J. Z., Anom, I. D. K. (2018). Briquettes Made with Mixtures of Salak Seed (Salacca zalacca) Charcoal and Coconut Shell Charcoal and the Potential as an Alternative Energy Source. International Journal of Applied Engineering Research, 13 (12), 10588–10592. Available at: https://www.ripublication.com/ijaer18/ijaerv13n12_64.pdf

- Musabbikhah, Saptoadi, H., Subarmono, Wibisono, M. A. (2016). Optimization of temperature and time for drying and carbonization to increase calorific value of coconut shell using Taguchi method. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.4943430

- Sagdinakiadtikul, T., Supakata, N. (2016). The application of using rice straw coconut shell and rice husk for briquette and charcoal production. International Journal of Energy, Environment and Economics, 24 (2/3), 283–292. Available at: https://www.proquest.com/docview/1903095179?fromopenview=true&pq-origsite=gscholar

- Djafar, Z., Suluh, S., Amaliyah, N., Piarah, W. H. (2022). Comparison of the Performance of Biomass Briquette Stoves on Three Types of Stove Wall Materials. International Journal of Design & Nature and Ecodynamics, 16 (6), 145–149. doi: https://doi.org/10.18280/ijdne.170119

- Djafar, Z., Amaliyah, N., Suluh, S., Isra, M., Piarah, W. H. (2020). The Performance of Clay Furnace with Variation in the Diameters of the Briquette Burning Chamber. IOP Conference Series: Materials Science and Engineering, 875 (1), 012068. doi: https://doi.org/10.1088/1757-899x/875/1/012068

- Wang, J., Lou, H. H., Yang, F., Cheng, F. (2016). Development and performance evaluation of a clean-burning stove. Journal of Cleaner Production, 134, 447–455. doi: https://doi.org/10.1016/j.jclepro.2016.01.068

- Orhevba, B. A., Olatunji, O. I., Obasa, P. A. (2018). Performance evaluation of a modified briquette stove. Nigerian Research Journal of Engineering and Environmental Sciences, 3 (2), 898–908. Available at: https://www.researchgate.net/publication/334330905_Performance_evaluation_of_a_modified_briquette_stove

- Tyagi, S. K., Pandey, A. K., Sahu, S., Bajala, V., Rajput, J. P. S. (2012). Experimental study and performance evaluation of various cook stove models based on energy and exergy analysis. Journal of Thermal Analysis and Calorimetry, 111 (3), 1791–1799. doi: https://doi.org/10.1007/s10973-012-2348-9

- Hailu, A. (2022). Development and performance analysis of top lit updraft: natural draft gasifier stoves with various feed stocks. Heliyon, 8 (8), e10163. doi: https://doi.org/10.1016/j.heliyon.2022.e10163

- Bokov, V., Sisa, O., Mirzak, V., Medvedieva, O. (2020). Pressing technology and burning quality of spherical fuel briquettes made from autumn leaves. Eastern-European Journal of Enterprise Technologies, 2 (1 (104)), 60–72. doi: https://doi.org/10.15587/1729-4061.2020.198724

- Okino, J., Komakech, A. J., Wanyama, J., Ssegane, H., Olomo, E., Omara, T. (2021). Performance Characteristics of a Cooking Stove Improved with Sawdust as an Insulation Material. Journal of Renewable Energy, 2021, 1–12. doi: https://doi.org/10.1155/2021/9969806

- Akolgo, G. A., Essandoh, E. O., Gyamfi, S., Atta-Darkwa, T., Kumi, E. N., Maia, C. M. B. de F. (2018). The potential of a dual purpose improved cookstove for low income earners in Ghana – Improved cooking methods and biochar production. Renewable and Sustainable Energy Reviews, 82, 369–379. doi: https://doi.org/10.1016/j.rser.2017.09.044

- Dang, H., Wang, G., Wang, C., Ning, X., Zhang, J., Mao, X. et al. (2021). Comprehensive Study on the Feasibility of Pyrolysis Biomass Char Applied to Blast Furnace Injection and Tuyere Simulation Combustion. ACS Omega, 6 (31), 20166–20180. doi: https://doi.org/10.1021/acsomega.1c01677

- Rasoulkhani, M., Ebrahimi-Nik, M., Abbaspour-Fard, M. H., Rohani, A. (2018). Comparative evaluation of the performance of an improved biomass cook stove and the traditional stoves of Iran. Sustainable Environment Research, 28 (6), 438–443. doi: https://doi.org/10.1016/j.serj.2018.08.001

- Bondarenko, I., Kutniashenko, O., Toporov, A., Anishchenko, L., Ziuz, O., Dunayev, I. et al. (2020). Improving the efficiency of equipment and technology of waste briquetting. Eastern-European Journal of Enterprise Technologies, 6 (10 (108)), 36–52. doi: https://doi.org/10.15587/1729-4061.2020.220349

- Murali, G., Channankaiah, P., Hasan, I. E., Anbarasan, P. (2015). Performance study of briquettes from agricultural waste for wood stove with catalytic combustor. International Journal of ChemTech Research, 8 (1), 30–36. Available at: https://sphinxsai.com/2015/ch_vol8_no1/1/(30-36)%20V8N1.pdf

- Panwar, N. L. (2010). Performance Evaluation of Developed Domestic Cook Stove with Jatropha Shell. Waste and Biomass Valorization, 1 (3), 309–314. doi: https://doi.org/10.1007/s12649-010-9040-8

- Ahiduzzaman, Md., Islam, A. K. M. S. (2013). Development of Biomass Stove for Heating up Die Barrel of Rice Husk Briquette Machine. Procedia Engineering, 56, 777–781. doi: https://doi.org/10.1016/j.proeng.2013.03.194

- Kumar, M., Kumar, S., Tyagi, S. K. (2013). Design, development and technological advancement in the biomass cookstoves: A review. Renewable and Sustainable Energy Reviews, 26, 265–285. doi: https://doi.org/10.1016/j.rser.2013.05.010

- MacCarty, N., Bryden, K. M. (2013). A Heat Transfer Model for the Conceptual Design of a Biomass Cookstove for Developing Countries. ASME 2013 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. doi: https://doi.org/10.1115/detc2013-12650

- Bentson, S., Evitt, D., Still, D., Lieberman, D., MacCarty, N. (2022). Retrofitting stoves with forced jets of primary air improves speed, emissions, and efficiency: Evidence from six types of biomass cookstoves. Energy for Sustainable Development, 71, 104–117. doi: https://doi.org/10.1016/j.esd.2022.09.013

- Ambreen, T., Saleem, A., Park, C. W. (2019). Pin-fin shape-dependent heat transfer and fluid flow characteristics of water- and nanofluid-cooled micropin-fin heat sinks: Square, circular and triangular fin cross-sections. Applied Thermal Engineering, 158, 113781. doi: https://doi.org/10.1016/j.applthermaleng.2019.113781

- Wang, J., Gan, Y., Liang, J., Tan, M., Li, Y. (2019). Sensitivity analysis of factors influencing a heat pipe-based thermal management system for a battery module with cylindrical cells. Applied Thermal Engineering, 151, 475–485. doi: https://doi.org/10.1016/j.applthermaleng.2019.02.036

- Li, X., He, L., Qian, P., Huang, Z., Luo, C., Liu, M. (2021). Heat transfer enhancement of droplet two-phase flow in cylindrical microchannel. Applied Thermal Engineering, 186, 116474. doi: https://doi.org/10.1016/j.applthermaleng.2020.116474

- Ikram, M. Md., Saha, G., Saha, S. C. (2023). Unsteady conjugate heat transfer characteristics in hexagonal cavity equipped with a multi-blade dynamic modulator. International Journal of Heat and Mass Transfer, 200, 123527. doi: https://doi.org/10.1016/j.ijheatmasstransfer.2022.123527

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Sallolo Suluh, Dennis Lorenza, Rigel Sampelolo, GAN Pongdatu, Dina Ramba, Agus Widyianto

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.