Substantiating the feasibility of processing the secondary product obtained after osmotic dehydration of dried apricots

DOI:

https://doi.org/10.15587/1729-4061.2024.309658Keywords:

derivative product, apricot, fortified sugar, food concentrates, osmotic dehydration, carotenoidsAbstract

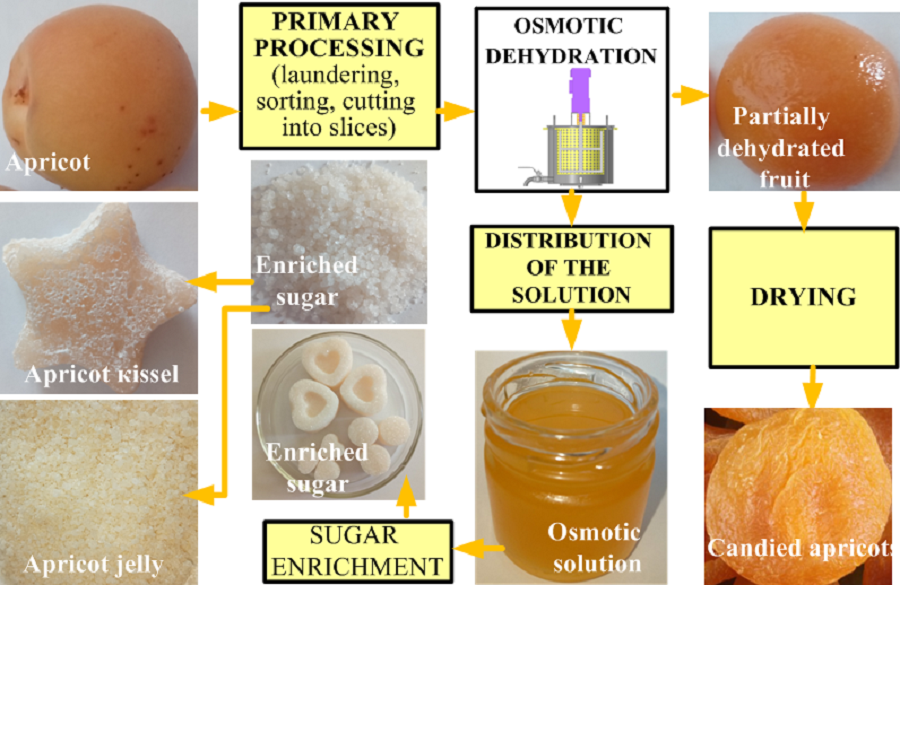

The object of research is the production technology of dried apricots by the method of osmotic dehydration and the derived products that are formed in the process. An improved technology for processing the secondary product of apricot production has been proposed, which is based on increasing the osmotic pressure in the cells of plant raw materials by increasing the concentration of dry substances. The improved technology involves the use of the process of osmotic dehydration in a 70 % sugar solution with a temperature of up to 55±5 °C as an alternative to the blanching process. This provides a reduction in drying time to 1 hour due to the partial transition of water from the fruit cells into the sugar solution. The spent osmotic solution contains biologically valuable substances. The mass fraction of dry substances in the spent solution decreased by 17.4 %. It was found that spent osmotic solutions contain 15.87±0.05 mg/100 carotenoids, which cause their orange color. Color stability is likely caused by the acidity of the osmotic solution (pH=3.7±0.05). As a result of hydrolysis, sucrose, which was the main component of the osmotic solution before dehydration of apricot fruits, is partially inverted into glucose (21.41±0.05) and fructose (19.99±0.05 g/100 g). Fortified sugar had a light beige color, pure without stains and impurities, sweet taste, and aroma of apricot. The jelly-like soft drink, made on the basis of a derivative product formed during the production of dried apricots, had a sweet taste, a slight aroma of apricot. The color of the meal is cream. Light straw-colored jelly, sweet in taste, with a faint aftertaste and aroma of apricot, had a jelly-like uniform consistency that can be cut. The study showed the possibility of practical application of derived products, which are usually disposed of, for production

References

- Dabija, A., Rusu, L., Codină, G. G. (2023). Studies on the Manufacturing of Food Products Using Unconventional Raw Materials. Applied Sciences, 13 (13), 7990. https://doi.org/10.3390/app13137990

- Scarano, P., Sciarrillo, R., Tartaglia, M., Zuzolo, D., Guarino, C. (2022). Circular economy and secondary raw materials from fruits as sustainable source for recovery and reuse. A review. Trends in Food Science & Technology, 122, 157–170. https://doi.org/10.1016/j.tifs.2022.02.003

- Albert, C., Codină, G. G., Héjja, M., András, C. D., Chetrariu, A., Dabija, A. (2022). Study of Antioxidant Activity of Garden Blackberries (Rubus fruticosus L.) Extracts Obtained with Different Extraction Solvents. Applied Sciences, 12 (8), 4004. https://doi.org/10.3390/app12084004

- Feng, X., Sun, J., Liu, B., Zhou, X., Jiang, L., Jiang, W. (2022). Effect of gradient concentration pre‐osmotic dehydration on keeping air‐dried apricot antioxidant activity and bioactive compounds. Journal of Food Processing and Preservation, 46 (7). https://doi.org/10.1111/jfpp.16688

- Wang, X., Feng, H. (2023). Investigating the Role Played by Osmotic Pressure Difference in Osmotic Dehydration: Interactions between Apple Slices and Binary and Multi-Component Osmotic Systems. Foods, 12 (17), 3179. https://doi.org/10.3390/foods12173179

- Giannakourou, M. C., Dermesonlouoglou, E. K., Taoukis, P. S. (2020). Osmodehydrofreezing: An Integrated Process for Food Preservation during Frozen Storage. Foods, 9 (8), 1042. https://doi.org/10.3390/foods9081042

- Yadav, A. K., Singh, S. V. (2012). Osmotic dehydration of fruits and vegetables: a review. Journal of Food Science and Technology, 51 (9), 1654–1673. https://doi.org/10.1007/s13197-012-0659-2

- Moraga, M. J., Moraga, G., Martínez-Navarrete, N. (2011). Effect of the re-use of the osmotic solution on the stability of osmodehydro-refrigerated grapefruit. LWT - Food Science and Technology, 44 (1), 35–41. https://doi.org/10.1016/j.lwt.2010.05.018

- Shete, Y. V., Chavan, S. M., Champawat, P. S., Jain, S. K. (2018). Reviews on osmotic dehydration of fruits and vegetables. Journal of Pharmacognosy and Phytochemistry, 7 (2), 1964–1969. Available at: https://www.phytojournal.com/archives/2018/vol7issue2/PartAB/7-2-141-966.pdf

- Fernández, P. R., Lovera, N., Ramallo, L. A. (2020). Sucrose syrup reuse during one‐ and multi‐stage osmotic dehydration of pineapple. Journal of Food Process Engineering, 43 (6). https://doi.org/10.1111/jfpe.13399

- Maldonado, R. R., Pedreira, A. J. R. M., Cristianini, L. B., Guidi, M. F., Capato, M. O., Ávila, P. F. et al. (2020). Application of soluble fibres in the osmotic dehydration of pineapples and reuse of effluent in a beverage fermented by water kefir. LWT, 132, 109819. https://doi.org/10.1016/j.lwt.2020.109819

- Chwastek, A., Klewicka, E., Klewicki, R., Sójka, M. (2015). Lactic Acid Fermentation of Red Beet Juice Supplemented with Waste Highbush Blueberry-Sucrose Osmotic Syrup as a Method of Probiotic Beverage Production. Journal of Food Processing and Preservation, 40 (4), 780–789. https://doi.org/10.1111/jfpp.12659

- Giannakourou, M. C., Lazou, A. E., Dermesonlouoglou, E. K. (2020). Optimization of Osmotic Dehydration of Tomatoes in Solutions of Non-Conventional Sweeteners by Response Surface Methodology and Desirability Approach. Foods, 9 (10), 1393. https://doi.org/10.3390/foods9101393

- Dermesonlouoglou, E. K., Giannakourou, M. C. (2018). Modelling dehydration of apricot in a non-conventional multi-component osmotic solution: effect on mass transfer kinetics and quality characteristics. Journal of Food Science and Technology, 55 (10), 4079–4089. https://doi.org/10.1007/s13197-018-3334-4

- Samilyk, M., Bal’-Prylipko, L., Korniienko, D., Paska, M., Ryzhkova, T., Yatsenko, I. et al. (2023). Determination of quality indicators of sugar fortified with a by-product of elderberry processing. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 65–72. https://doi.org/10.15587/1729-4061.2023.284885

- Jan, N., Anjum, S., Wani, S. M., Mir, S. A., Malik, A. R., Wani, S. A. et al. (2022). Influence of Canning and Storage on Physicochemical Properties, Antioxidant Properties, and Bioactive Compounds of Apricot (Prunus armeniaca L.) Wholes, Halves, and Pulp. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.850730

- Dermesonlouoglou, E. K., Giannakourou, M. C. (2018). Modelling dehydration of apricot in a non-conventional multi-component osmotic solution: effect on mass transfer kinetics and quality characteristics. Journal of Food Science and Technology, 55 (10), 4079–4089. https://doi.org/10.1007/s13197-018-3334-4

- Zhou, W., Niu, Y., Ding, X., Zhao, S., Li, Y., Fan, G. et al. (2020). Analysis of carotenoid content and diversity in apricots (Prunus armeniaca L.) grown in China. Food Chemistry, 330, 127223. https://doi.org/10.1016/j.foodchem.2020.127223

- Pintea, A., Dulf, F. V., Bunea, A., Socaci, S. A., Pop, E. A., Opriță, V.-A. et al. (2020). Carotenoids, Fatty Acids, and Volatile Compounds in Apricot Cultivars from Romania – A Chemometric Approach. Antioxidants, 9 (7), 562. https://doi.org/10.3390/antiox9070562

- Naryal, A., Acharya, S., Kumar Bhardwaj, A., Kant, A., Chaurasia, O. P., Stobdan, T. (2019). Altitudinal effect on sugar contents and sugar profiles in dried apricot (Prunus armeniaca L.) fruit. Journal of Food Composition and Analysis, 76, 27–32. https://doi.org/10.1016/j.jfca.2018.11.003

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Maryna Samilyk, Mykhaylo Tkachuk, Mariia Paska, Taisia Ryzhkova, Svetlana Tkachuk, Alla Petrenko, Dmytro Hrinchenko, Petro Gurskyi, Liubov Savchuk, Tetyana Yarmosh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.