Identifying the influence of the pitch of hammers with cutting edges on the average length of feed crushed in hammer grinders

DOI:

https://doi.org/10.15587/1729-4061.2024.310045Keywords:

grinder, length of grinding, edges of adjacent hammers, angle of stem arrangementAbstract

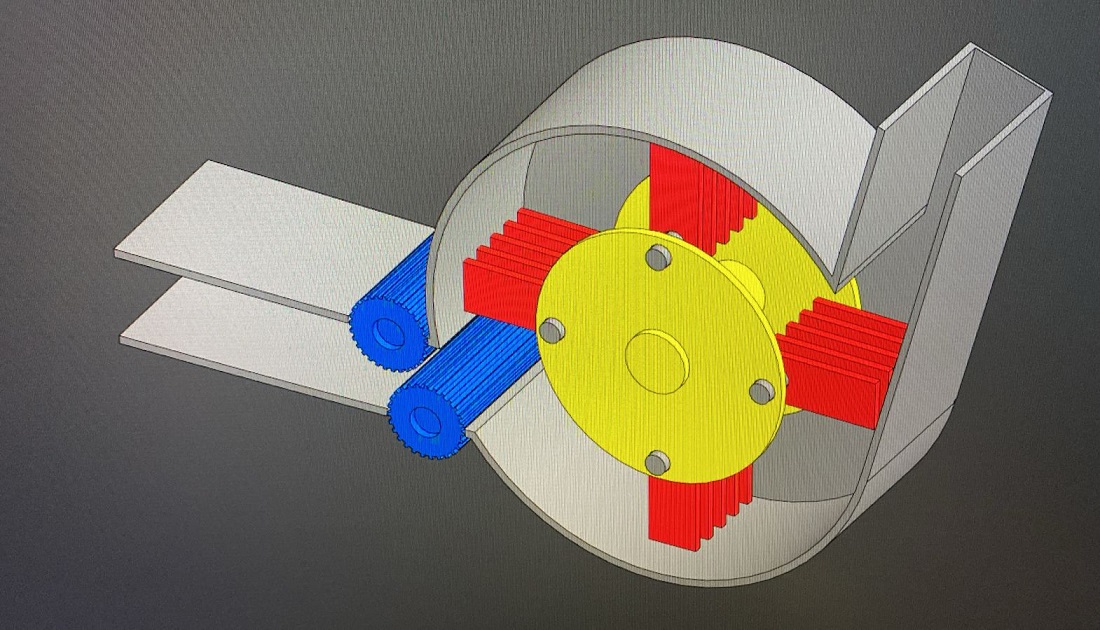

The object of the research is to identify the influence of the pitch of the hammers with cutting edges on the determination of the average length of feed, crushed from by-product stem raw materials in hammer crushers. However, a problem was identified such as the lack of an analytical expression for determining the average length of chopped stem feed by a hammer grinder depending on the distance between the edges of adjacent hammers. With a simultaneous change in the angles of the location of the stem with the maximum size in the layer and, using the methods of probability theory for determining the mathematical descriptions of the function of two arguments, in this study an analytical expression was obtained for determining the average length of particles crushed by hammer crushers depending on the distance between the faces of adjacent hammers. Hammers with cutting edges are used to crush feed from by-product stem raw materials. The end working part of the hammer is milled at an angle of 90°, i.e. two cutting edges are processed at the end of the hammer. As a result of the practical calculations, the average length of feed crushed from by-product stem raw materials was determined depending on the parameters of the hammer crusher. From the resulting graph of the influence of the distance between the faces of adjacent hammers on the average length of crushed particles, it is evident that when the distance between the faces of adjacent hammers changes, the average length of crushed particles varies within the range of 36.19...53.39 mm. To verify the reliability of the obtained expression, experiments were carried out on a crusher with a distance between the faces of adjacent hammers of 20 mm. In this case, the average length of the crushed particles was equal to 38.75 mm, and the theoretical value was 40.16 mm. The difference between them was 3.64 %, which proves the reliability of the obtained analytical expression. The conducted theoretical studies with the receipt of an analytical expression, ensuring the determination of the average length of feed, chopped from by-product stem raw materials, is the solution to an important problem in the development of theoretical foundations of chopping machines, significantly affecting the efficiency of mechanization and operation of feed choppers in practice

Supporting Agency

- This research has been/was/is funded by the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan (Grant No. AP19679802).

References

- Iskakov, R., Sugirbay, A. (2023). Technologies for the Rational Use of Animal Waste: A Review. Sustainability, 15 (3), 2278. https://doi.org/10.3390/su15032278

- Iskakov, R. M., Iskakova, A. M., Nurushev, M. Z., Khaimuldinova, A. K., Karbayev, N. K. (2021). Method for the Production of Fat from Raw Materials and Animal Waste. Journal of Pure and Applied Microbiology, 15 (2), 716–724. https://doi.org/10.22207/jpam.15.2.23

- Jinxin, W., Zhiping, Z., Yuezheng, L., Xiaoyi, Z., Lixiang, Z. (2023). Reliability Analysis and Optimization of Forage Crushers Based on Bayesian Network. International Journal of Performability Engineering, 19 (10), 700. https://doi.org/10.23940/ijpe.23.10.p7.700709

- Ding, L., Li, J., Kan, Z., Lei, S., Li, N., Ren, H. (2022). Wear Behavior between a Jujube Branch and a Hammer Claw of a Jujube Branch Crusher. Applied Engineering in Agriculture, 38 (5), 719–727. https://doi.org/10.13031/aea.15004

- Mou, X., Wan, F., Wu, J., Luo, Q., Xin, S., Ma, G. et al. (2024). Simulation Analysis and Multiobjective Optimization of Pulverization Process of Seed-Used Watermelon Peel Pulverizer Based on EDEM. Agriculture, 14 (2), 308. https://doi.org/10.3390/agriculture14020308

- Kuzmenko, V., Bratishko, V., Subota, S., Kholodiuk, O. (2023). Influence of moisture on particle size of plant raw materials after grinding. 22nd International Scientific Conference Engineering for Rural Development Proceedings. https://doi.org/10.22616/erdev.2023.22.tf122

- Sherov, K. T., Alikulov, D. E., Sikhimbayev, M. R., Sherov, A. K., Absadykov, B. N., Imanbaev, E. B., Gabdysalyk, R. (2021). The method of selecting the optimal layouts of the size limit deviations during assembly. News of the National Academy of Sciences of the Republic of Kazakhstan. Series of geology and technology sciences, 1 (445), 144–150. https://doi.org/10.32014/2021.2518-170x.20

- Zhang, J., Feng, B., Yu, X., Zhao, C., Li, H., Kan, Z. (2022). Experimental Study on the Crushing Properties of Corn Stalks in Square Bales. Processes, 10 (1), 168. https://doi.org/10.3390/pr10010168

- Zhao, Y., Zhai, Z., Gao, B., Lan, Y. (2024). Numerical prediction and optimization of aerodynamic noise of straw crushers by considering the straw-crushing process. Physics of Fluids, 36 (4). https://doi.org/10.1063/5.0204245

- Abilzhanuly, T. (2019). Method of Fineness Adjustment of Shredded Particles of Stem Fodder in Open-type Machines. EurAsian Journal of BioSciences, 13 (1), 625–631.

- Shukhanov, S. N., Vasil'yev, N. F. (2011). Moderirovaniye protsessa razrusheniya zernovykh chastits na bezreshetochnom izmel'chitele. Khraneniye i pererabotka sel'khozsyr'ya, 2, 27–28.

- Globin, A. N. (2017). Moderirovaniye protsessa dozirovannoy vydachi shtrafnykh stebel'nykh kormov. Tekhnologii, sredstva mekhanizatsii i energeticheskoye oborudovaniye, 1 (37), 5–15.

- Abilzhanuly, T., Iskakov, R., Abilzhanov, D., Darkhan, O. (2023). Determination of the average size of preliminary grinded wet feed particles in hammer grinders. Eastern-European Journal of Enterprise Technologies, 1 (1 (121)), 34–43. https://doi.org/10.15587/1729-4061.2023.268519

- Astanakulov, K., Karshiev, F., Gapparov, S., Khudaynazarov, D., Azizov, S. (2021). Mini crusher-shredder for farms. E3S Web of Conferences, 264, 04038. https://doi.org/10.1051/e3sconf/202126404038

- Zhang, X., Gan, S., Zheng, K., Li, Y., Liang, D. (2015). Design and experiment on cut roll feeding type horizontal shaft flail machine for banana pseudostem crushing and returning. Nongye Gongcheng Xuebao/Transactions of the Chinese Society of Agricultural Engineering, 4, 33–41. http://dx.doi.org/10.3969/j.issn.1002-6819.2015.04.005

- Revenko, I., Khmelovskyi, V., Revenko, Y., Rebenko, V., Potapova, S. (2023). Justification of parameters affecting increase of hammer crusher productivity. 22nd International Scientific Conference Engineering for Rural Development Proceedings. https://doi.org/10.22616/erdev.2023.22.tf142

- Maiviatov, F., Karshiev, F., Gapparov, S. (2021). Movement of crushed stem particles when they interact with hammers. IOP Conference Series: Earth and Environmental Science, 868 (1), 012060. https://doi.org/10.1088/1755-1315/868/1/012060

- Graham, R. (2022). Designing a device to assist shredder hammer-grid bar clearance tuning. Proceedings of the Australian Society of Sugar Cane Technologists.

- Ulanov, I. A. (1976). Mashiny dlya izmel'cheniya kormov (teoriya i raschet). Saratov, 86.

- Маmatov, F., Karshiev, F., Umirov, A., Gapparov, S., Shamayev, Y., Axmedova, D., Khodiboev, Y. (2024). Determination of grinding condition by grain elasticity and hammer width for sustainable feed production in livestock farming. BIO Web of Conferences, 105, 05008. https://doi.org/10.1051/bioconf/202410505008

- Venttsel', Ye. S. (2001). Teoriya veroyatnostey. Moscow: Vysshaya shkola, 575.

- Aytbayev, M. M., Kurmanov, A. K. (2019). Razrabotka i obosnovaniye konstruktivno-rezhimnykh parametrov drobilki termoobrabotannykh kormov. Kostanay: Kostanayskiy sotsial'no-tekhnicheskiy universitet, 104.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Tokhtar Abilzhanuly, Ruslan Iskakov, Daniyar Abilzhanov, Alexandr Gulyarenko, Valery Khan

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.