Development of technology for food products with emulsion structure based on pea groats and pea aquafaba

DOI:

https://doi.org/10.15587/1729-4061.2025.323339Keywords:

pea groats, aquafaba, vegetable appetizers, emulsion structure, rheological indicators, microstructureAbstract

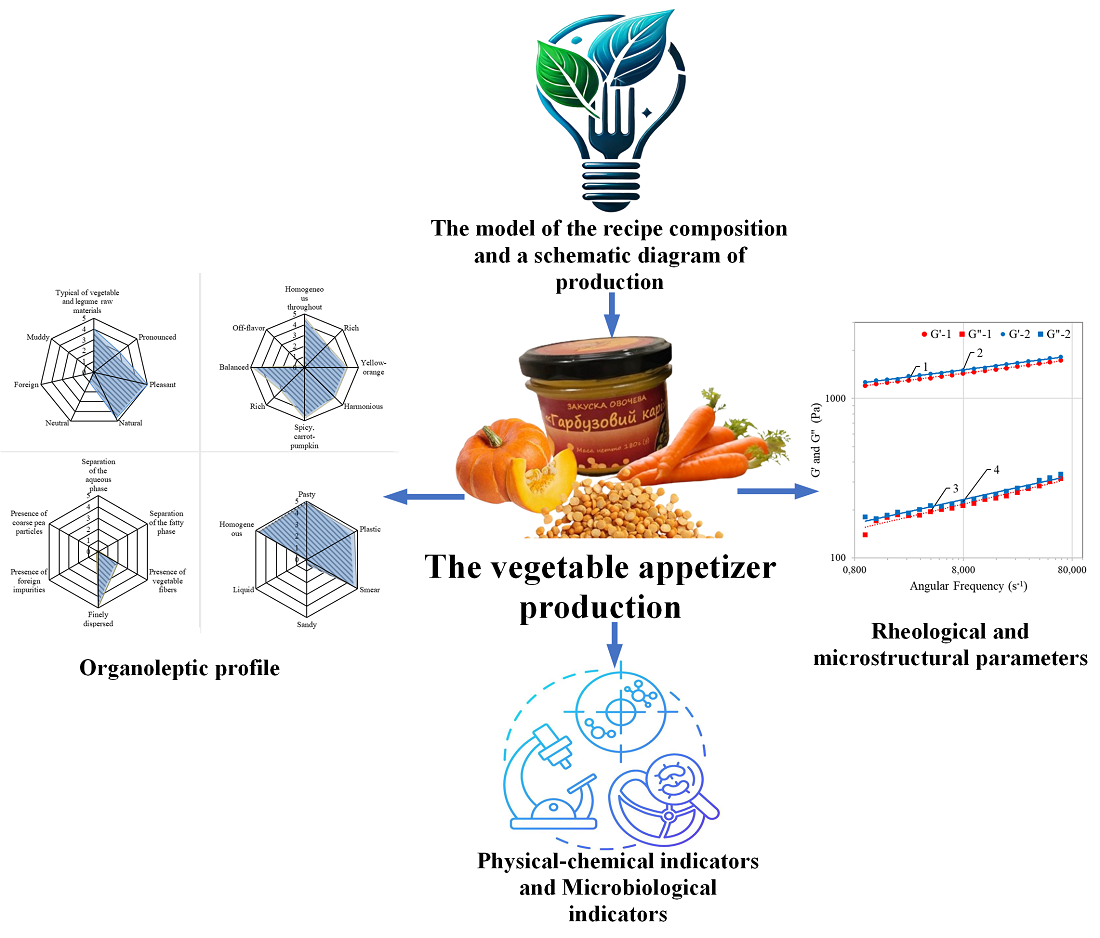

The object of this study is a vegetable appetizer, as well as its sensory, physicochemical, microbiological, rheological, microstructural indicators, and their changes after 30 days of storage.

The main task addressed within the framework of the study was the implementation of both pea groats (the basic raw material) and pea aquafaba (an intermediate semi-finished product) in one technological flow of food production. This approach contributes to the rational use of resources, the implementation of scientifically based parameters of the technological process, and the practical implementation of sustainable development concepts through the valorization of intermediate semi-finished products.

A model of the recipe composition and a schematic diagram of food products with an emulsion structure based on pea groats and pea aquafaba have been developed. It has been experimentally determined that the developed products are characterized by high sensory indicators that remain stable during storage. The mass fraction of dry matter in the studied samples was 45.1 %, the mass fraction of protein was 4.3 %, and the carbohydrates were 13.6 %. The water activity in freshly prepared appetizers was 0.910, and after 30 days of storage, it was 0.902. Rheological and microstructural indicators confirmed the formation of a stable multicomponent structure.

A distinctive feature of the experimental results is that the emulsion structure of the developed food product is provided with the technological properties of aquafaba.

The technological solutions proposed in this work aim to make food products that meet the growing demand for plant-based, functional, and economically affordable products. The practical implementation of the devised technology could contribute to meeting consumer demands and introducing innovative trends in the development of the food industry, through resource efficiency of production processes

References

- Olsmats, E., Rennie, A. R. (2024). Pea protein [Pisum sativum] as stabilizer for oil/water emulsions. Advances in Colloid and Interface Science, 326, 103123. https://doi.org/10.1016/j.cis.2024.103123

- Sridharan, S., Meinders, M. B. J., Bitter, J. H., Nikiforidis, C. V. (2020). Pea flour as stabilizer of oil-in-water emulsions: Protein purification unnecessary. Food Hydrocolloids, 101, 105533. https://doi.org/10.1016/j.foodhyd.2019.105533

- Koksel, F., Masatcioglu, M. T. (2018). Physical properties of puffed yellow pea snacks produced by nitrogen gas assisted extrusion cooking. LWT, 93, 592–598. https://doi.org/10.1016/j.lwt.2018.04.011

- Kilicli, M., Özmen, D., Bayram, M., Toker, O. S. (2023). Usage of green pea aquafaba modified with ultrasonication in production of whipped cream. International Journal of Gastronomy and Food Science, 32, 100724. https://doi.org/10.1016/j.ijgfs.2023.100724

- Damian, J. J., Huo, S., Serventi, L. (2018). Phytochemical content and emulsifying ability of pulses cooking water. European Food Research and Technology, 244 (9), 1647–1655. https://doi.org/10.1007/s00217-018-3077-5

- Oktay, M., Kirkin Gözükirmizi, C. (2023). Utilization of the aquafaba of canned chickpea and green pea in the production of vegan mayonnaise. Harran Tarım ve Gıda Bilimleri Dergisi, 27 (1), 94–102. https://doi.org/10.29050/harranziraat.1149631

- Hrynchenko, O., Dehtiar, V., Radchenko, A., Pak, A., Smetanska, I., Percevoy, F. (2024). Revealing the effect of hydrothermal processing of legumes on the accumulation of dry matter in aquafaba. Eastern-European Journal of Enterprise Technologies, 5 (11 (131)), 51–61. https://doi.org/10.15587/1729-4061.2024.313890

- Sachko, A., Sema, O., Grinchenko, O., Gubsky, S. (2023). Canned Beans Aquafaba as an Egg White Substitute in the Technology of Low-Fat Mayonnaise. The 4th International Electronic Conference on Applied Sciences, 206. https://doi.org/10.3390/asec2023-16291

- McClements, D. J. (2015). Food Emulsions. CRC Press, 714. https://doi.org/10.1201/b18868

- Alvarez, M., Fuentes, R., Canet, W. (2015). Effects of Pressure, Temperature, Treatment Time, and Storage on Rheological, Textural, and Structural Properties of Heat-Induced Chickpea Gels. Foods, 4 (2), 80–114. https://doi.org/10.3390/foods4020080

- Sudheesh, C., Sunooj, K. V., Sinha, S. K., George, J., Kumar, S., Murugesan, P. et al. (2019). Impact of energetic neutral nitrogen atoms created by glow discharge air plasma on the physico-chemical and rheological properties of kithul starch. Food Chemistry, 294, 194–202. https://doi.org/10.1016/j.foodchem.2019.05.067

- Guimarães, C. F., Gasperini, L., Ribeiro, R. S., Carvalho, A. F., Marques, A. P., Reis, R. L. (2020). High-throughput fabrication of cell-laden 3D biomaterial gradients. Materials Horizons, 7 (9), 2414–2421. https://doi.org/10.1039/d0mh00818d

- Horalchuk, A. B., Pyvovarov, P. P., Hrynchenko, O. O., Pohozhykh, M. I., Polevych, V. V., Hurskyi, P. V. (2006). Reolohichni metody doslidzhennia syrovyny i kharchovykh produktiv ta avtomatyzatsiya rozrakhunkiv reolohichnykh kharakterystyk. Kharkiv: KhDUKhT, 63. https://doi.org/10.13140/RG.2.1.2739.7847

- Mezger, T. G. (2012). The Rheology Handbook. Vincentz Network, 432. https://doi.org/10.1515/9783748600367

- Pycia, K., Juszczak, L. (2022). The Effect of the Addition of Hazelnut or Walnut Flour on the Rheological Characteristics of Wheat Dough. Materials, 15 (3), 782. https://doi.org/10.3390/ma15030782

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Olha Hrynchenko, Anna Radchenko, Valentyna Dehtiar, Nataliya Grynchenko, Maksym Serik

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.