Designing the structure and determining the operating parameters of a microwave dehydrator for obtaining phyto-concentrates

DOI:

https://doi.org/10.15587/1729-4061.2025.335177Keywords:

microwave field, dehydrator, phyto-concentrate, productivity, solvent, ascorbic acidAbstract

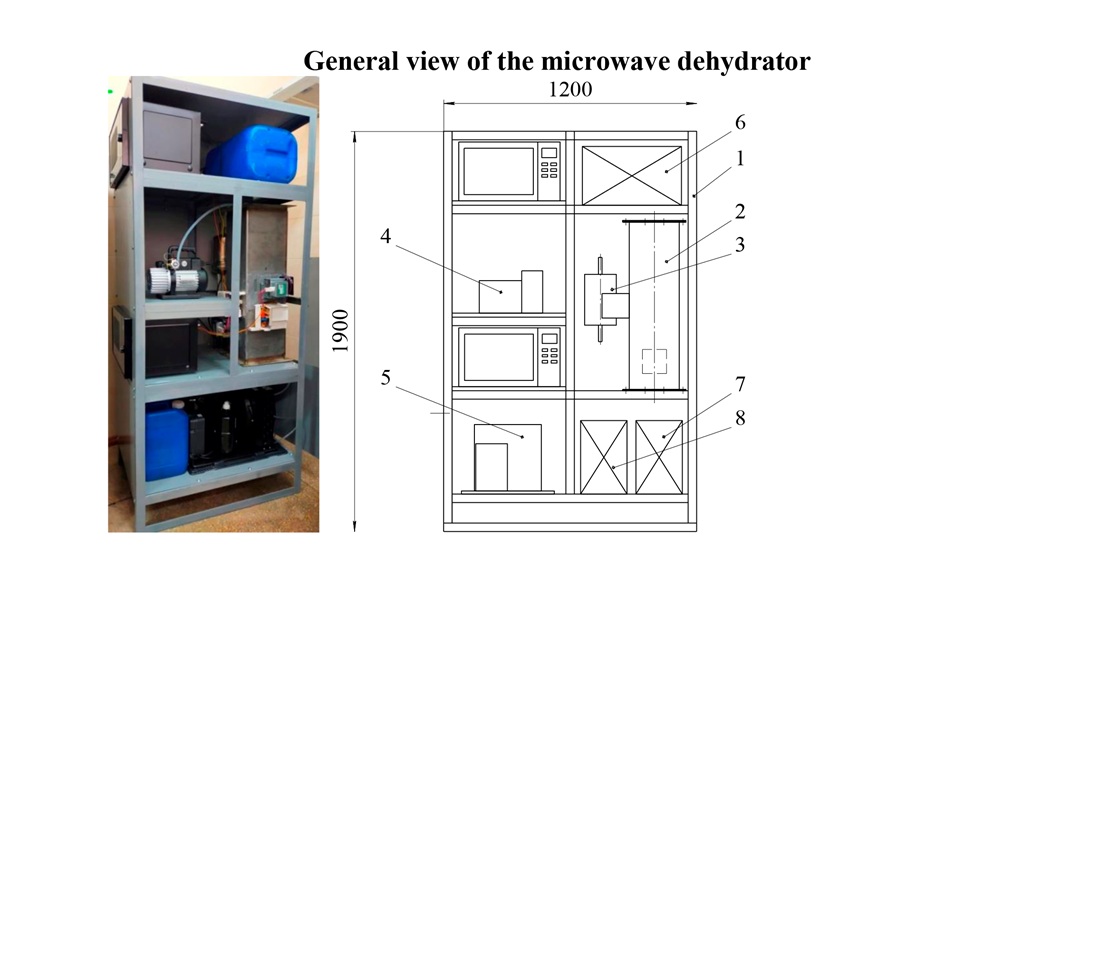

This study's object is the process of obtaining phyto-concentrates using a continuous microwave dehydrator. The task addressed is associated with the concentration of food solutions in existing evaporators: product sticking to heat exchange surfaces, change in product quality, the need for additional systems for mixing, high energy consumption, inability to achieve high concentrations.

The structure of a microwave dehydrator operates under periodic and continuous modes. The dehydrator's productivity has been determined depending on microwave field power, solution type, as well as product type. Wine, apple, and grape juices; coffee and echinacea extracts, as well as extracts with acetone solvent, were investigated as solutions. For water-containing products, the productivity value varied in the range of 0.28…0.32 kg/h.

The dehydrator's operating modes have been defined, enabling the preservation of heat-sensitive components of the raw materials. The highest content of ascorbic acid was found in the concentrate of actinidia berries (375 mg) and bioflavonoids (18.5 mg). The concentrate of grape juice exceeds the control sample (directly squeezed juice) by 6.5 times.

The high quality indicators of the product and low energy consumption of the dehydrator are attributed to the selectivity of microwave heating, which has a directed effect on polar molecules of moisture and solvent, without overheating the raw materials. The dehydrator was operated under a continuous mode, which makes it possible to increase productivity, processing quality, reduce metal consumption, and simplify its structure. The energy efficiency of the dehydrator is also based on the fact that due to its use it is possible to exclude a conventional dryer from the technological chain.

A feature of the dehydrator design is the lack of need for constant operation of the vacuum pump, which ultimately reduces energy consumption.

The scope of its application includes food and processing sectors, production of phyto-concentrates, functional drinks, as well as additives. Conditions of use: small businesses and farms working with heat-sensitive raw materials

References

- Burdo, O. G., Terziev, S. G., Gavrilov, A. V., Sirotyuk, I. V., Shcherbich, M. V. (2020). System of Innovative Energy Technologies of Food Raw Material Dehydration. Problemele Energeticii Regionale, 2 (46), 92–107. https://doi.org/10.5281/zenodo.3898317

- Ibis, O. I., Bugday, Y. B., Aljurf, B. N., Goksu, A. O., Solmaz, H., Oztop, M. H., Sumnu, G. (2024). Crystallization of sucrose by using microwave vacuum evaporation. Journal of Food Engineering, 365, 111847. https://doi.org/10.1016/j.jfoodeng.2023.111847

- Carvalho, G. R., Monteiro, R. L., Laurindo, J. B., Augusto, P. E. D. (2021). Microwave and microwave-vacuum drying as alternatives to convective drying in barley malt processing. Innovative Food Science & Emerging Technologies, 73, 102770. https://doi.org/10.1016/j.ifset.2021.102770

- Dumpler, J., Moraru, C. I. (2024). Microwave vacuum drying of dairy cream: Processing, reconstitution, and whipping properties of a novel dairy product. Journal of Dairy Science, 107 (2), 774–789. https://doi.org/10.3168/jds.2023-23657

- Kalinke, I., Kulozik, U. (2024). Enhancing Microwave Freeze Drying: Exploring Maximum Drying Temperature and Power Input for Improved Energy Efficiency and Uniformity. Food and Bioprocess Technology, 17 (12), 5357–5371. https://doi.org/10.1007/s11947-024-03438-5

- Kalinke, I., Röder, J., Unterbuchberger, G., Kulozik, U. (2025). Microwave-assisted freeze drying: The role of power input and temperature control on energy efficiency and uniformity. Journal of Food Engineering, 390, 112410. https://doi.org/10.1016/j.jfoodeng.2024.112410

- Sujinda, N., Varith, J., Shamsudin, R., Jaturonglumlert, S., Chamnan, S. (2021). Development of a closed-loop control system for microwave freeze-drying of carrot slices using a dynamic microwave logic control. Journal of Food Engineering, 302, 110559. https://doi.org/10.1016/j.jfoodeng.2021.110559

- Wu, Y., Mu, R., Li, G., Li, M., Lv, W. (2022). Research progress in fluid and semifluid microwave heating technology in food processing. Comprehensive Reviews in Food Science and Food Safety, 21 (4), 3436–3454. https://doi.org/10.1111/1541-4337.12978

- Li, M., Zhou, C., Wang, B., Zeng, S., Mu, R., Li, G. et al. (2023). Research progress and application of ultrasonic‐ and microwave‐assisted food processing technology. Comprehensive Reviews in Food Science and Food Safety, 22 (5), 3707–3731. https://doi.org/10.1111/1541-4337.13198

- Zhou, S., Chen, W., Fan, K. (2024). Recent advances in combined ultrasound and microwave treatment for improving food processing efficiency and quality: A review. Food Bioscience, 58, 103683. https://doi.org/10.1016/j.fbio.2024.103683

- Hameed, A., Maan, A. A., Khan, M. K. I., Mahmood Khan, I., Niazi, S., Waheed Iqbal, M. et al. (2023). Evaporation kinetics and quality attributes of grape juice concentrate as affected by microwave and vacuum processing. International Journal of Food Properties, 26 (1), 1596–1611. https://doi.org/10.1080/10942912.2023.2218062

- Pinto, R. O. M., do Nascimento, R. B., Jermolovicius, L. A., Jurkiewicz, C., Gut, J. A. W., Pinto, U. M., Landgraf, M. (2021). Microbiological feasibility of microwave processing of coconut water. LWT, 145, 111344. https://doi.org/10.1016/j.lwt.2021.111344

- Kutlu, N., Pandiselvam, R., Saka, I., Kamiloglu, A., Sahni, P., Kothakota, A. (2021). Impact of different microwave treatments on food texture. Journal of Texture Studies, 53 (6), 709–736. https://doi.org/10.1111/jtxs.12635

- Guzik, P., Kulawik, P., Zając, M., Migdał, W. (2021). Microwave applications in the food industry: an overview of recent developments. Critical Reviews in Food Science and Nutrition, 62 (29), 7989–8008. https://doi.org/10.1080/10408398.2021.1922871

- Araujo, R. G., Rodríguez-Jasso, R. M., Ruíz, H. A., Govea-Salas, M., Pintado, M., Aguilar, C. N. (2021). Recovery of bioactive components from avocado peels using microwave-assisted extraction. Food and Bioproducts Processing, 127, 152–161. https://doi.org/10.1016/j.fbp.2021.02.015

- Akpinar, E. K. (2004). Energy and exergy analyses of drying of red pepper slices in a convective type dryer. International Communications in Heat and Mass Transfer, 31 (8), 1165–1176. https://doi.org/10.1016/j.icheatmasstransfer.2004.08.014

- Kavak Akpinar, E., Midilli, A., Bicer, Y. (2005). Energy and exergy of potato drying process via cyclone type dryer. Energy Conversion and Management, 46 (15-16), 2530–2552. https://doi.org/10.1016/j.enconman.2004.12.008

- Mustaffar, A., Phan, A., Boodhoo, K. (2018). Hybrid heat pipe screw dryer: A novel, continuous and highly energy-efficient drying technology. Chemical Engineering and Processing - Process Intensification, 128, 199–215. https://doi.org/10.1016/j.cep.2018.04.035

- Asghar, M. T., Yusof, Y. A., Mokhtar, M. N., Yaacob, M. E., Ghazali, H. M., Varith, J. et al. (2020). Processing of coconut sap into sugar syrup using rotary evaporation, microwave, and open-heat evaporation techniques. Journal of the Science of Food and Agriculture, 100 (10), 4012–4019. https://doi.org/10.1002/jsfa.10446

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleg Burdo, Igor Bezbakh, Mykola Kepin, Alla Burdo, Igor Yevtushenko, Natalya Bahmutian, Lyudmila Phylipova, Dmytro Kharenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.