Розробка конструкції та визначення режимних параметрів мікрохвильового дегідратора для отримання фіто концентратів

DOI:

https://doi.org/10.15587/1729-4061.2025.335177Ключові слова:

мікрохвильове поле, дегідратор, фіто концентрат, продуктивність, розчинник, аскорбінова кислотаАнотація

Об’єктом дослідження є процес отримання фіто концентратів з використанням мікрохвильового дегідратора безперервної дії. Вирішувались проблеми пов'язані з концентруванням харчових розчинів в існуючих випарних апаратах: пригоряння продукту до теплообмінних поверхонь, зміна якості продукту, необхідність додаткових систем для перемішування, високі енерговитрати, неможливість досягнення високих концентрацій.

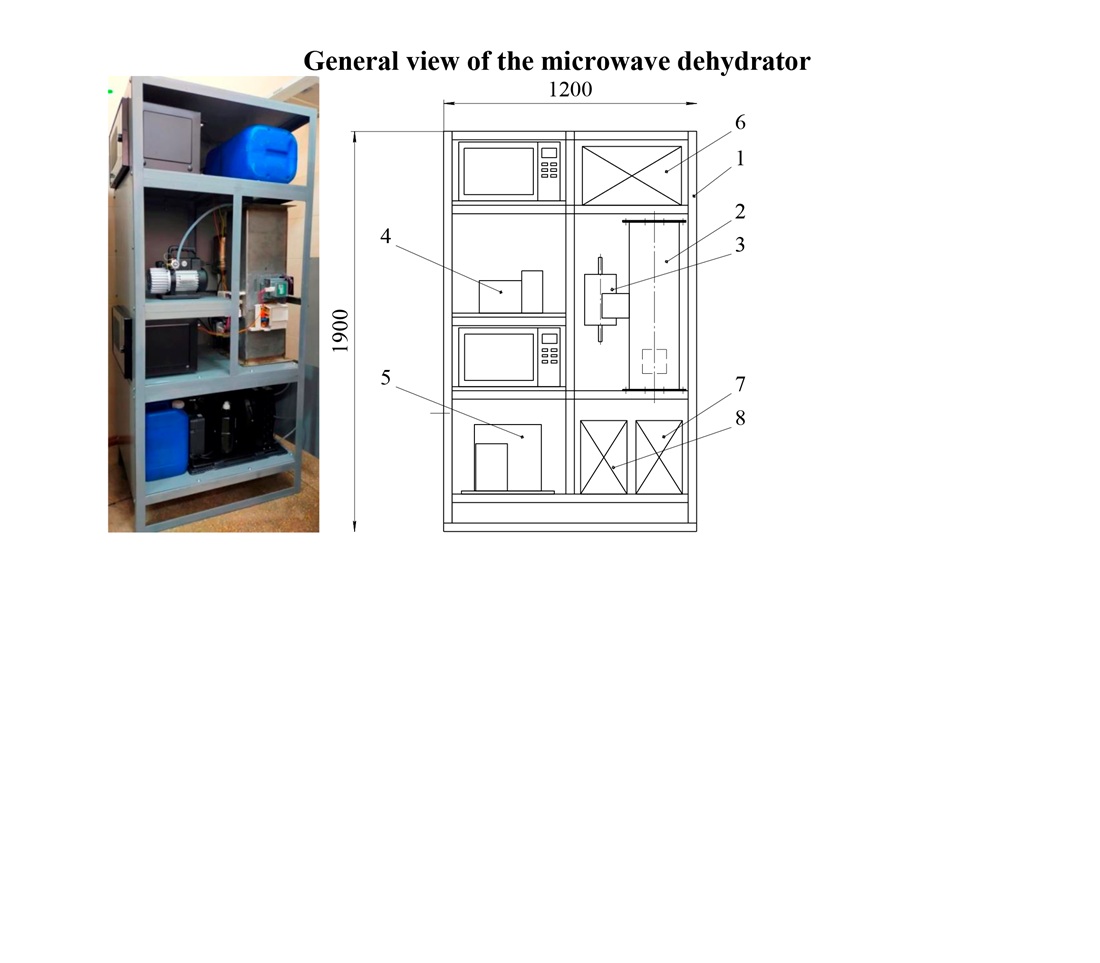

Конструкція мікрохвильового дегідратору працює у періодичному та безперервному режимі. Визначено продуктивність дегідратора в залежності від: потужності мікрохвильового поля, типу розчину та продукту. В якості розчинів досліджено вино, соки із яблука та винограду; екстракти кави, ехінацеї, екстракти із розчинником ацетоном. Для водовмісних продуктів значення продуктивності змінюється в діапазоні 0,28…0,32 кг/год.

Визначено режими роботи дегідратора, що забезпечують збереження термочутливих компонентів сировини. Найбільший вміст аскорбінової кислоти має концентрат з ягід актинідії (375 мг), біофлаваноїдів (18,5 мг). Концентрат з соку виноградного перевищує контрольний зразок (сік прямого віджиму) у 6,5 разів.

Високі якісні показники продукту та низьке енергоспоживання дегідратора пояснюється вибірковістю мікрохвильового нагрівання, що спрямовано впливає на полярні молекули вологи та розчинника, не перегріваючи сировину. Робота дегідратора проводилась у режимі безперервної дії, що дозволяє підвищити продуктивність, якість обробки, знизити металоємність та спростити конструкцію. Енергоефективність дегідратора також визначається тим, що за рахунок його застосування можливо виключити з технологічного ланцюгу традиційну сушарку.

Особливістю конструкції дегідратора є відсутність потреби в постійній роботі вакуумного насоса, що знижує енергоспоживання.

Сфера застосування – харчова та переробна промисловість, виробництво фітоконцентратів, функціональних напоїв, добавок. Умови використання – малі підприємства та фермерські господарства, що працюють з термочутливою сировиною

Посилання

- Burdo, O. G., Terziev, S. G., Gavrilov, A. V., Sirotyuk, I. V., Shcherbich, M. V. (2020). System of Innovative Energy Technologies of Food Raw Material Dehydration. Problemele Energeticii Regionale, 2 (46), 92–107. https://doi.org/10.5281/zenodo.3898317

- Ibis, O. I., Bugday, Y. B., Aljurf, B. N., Goksu, A. O., Solmaz, H., Oztop, M. H., Sumnu, G. (2024). Crystallization of sucrose by using microwave vacuum evaporation. Journal of Food Engineering, 365, 111847. https://doi.org/10.1016/j.jfoodeng.2023.111847

- Carvalho, G. R., Monteiro, R. L., Laurindo, J. B., Augusto, P. E. D. (2021). Microwave and microwave-vacuum drying as alternatives to convective drying in barley malt processing. Innovative Food Science & Emerging Technologies, 73, 102770. https://doi.org/10.1016/j.ifset.2021.102770

- Dumpler, J., Moraru, C. I. (2024). Microwave vacuum drying of dairy cream: Processing, reconstitution, and whipping properties of a novel dairy product. Journal of Dairy Science, 107 (2), 774–789. https://doi.org/10.3168/jds.2023-23657

- Kalinke, I., Kulozik, U. (2024). Enhancing Microwave Freeze Drying: Exploring Maximum Drying Temperature and Power Input for Improved Energy Efficiency and Uniformity. Food and Bioprocess Technology, 17 (12), 5357–5371. https://doi.org/10.1007/s11947-024-03438-5

- Kalinke, I., Röder, J., Unterbuchberger, G., Kulozik, U. (2025). Microwave-assisted freeze drying: The role of power input and temperature control on energy efficiency and uniformity. Journal of Food Engineering, 390, 112410. https://doi.org/10.1016/j.jfoodeng.2024.112410

- Sujinda, N., Varith, J., Shamsudin, R., Jaturonglumlert, S., Chamnan, S. (2021). Development of a closed-loop control system for microwave freeze-drying of carrot slices using a dynamic microwave logic control. Journal of Food Engineering, 302, 110559. https://doi.org/10.1016/j.jfoodeng.2021.110559

- Wu, Y., Mu, R., Li, G., Li, M., Lv, W. (2022). Research progress in fluid and semifluid microwave heating technology in food processing. Comprehensive Reviews in Food Science and Food Safety, 21 (4), 3436–3454. https://doi.org/10.1111/1541-4337.12978

- Li, M., Zhou, C., Wang, B., Zeng, S., Mu, R., Li, G. et al. (2023). Research progress and application of ultrasonic‐ and microwave‐assisted food processing technology. Comprehensive Reviews in Food Science and Food Safety, 22 (5), 3707–3731. https://doi.org/10.1111/1541-4337.13198

- Zhou, S., Chen, W., Fan, K. (2024). Recent advances in combined ultrasound and microwave treatment for improving food processing efficiency and quality: A review. Food Bioscience, 58, 103683. https://doi.org/10.1016/j.fbio.2024.103683

- Hameed, A., Maan, A. A., Khan, M. K. I., Mahmood Khan, I., Niazi, S., Waheed Iqbal, M. et al. (2023). Evaporation kinetics and quality attributes of grape juice concentrate as affected by microwave and vacuum processing. International Journal of Food Properties, 26 (1), 1596–1611. https://doi.org/10.1080/10942912.2023.2218062

- Pinto, R. O. M., do Nascimento, R. B., Jermolovicius, L. A., Jurkiewicz, C., Gut, J. A. W., Pinto, U. M., Landgraf, M. (2021). Microbiological feasibility of microwave processing of coconut water. LWT, 145, 111344. https://doi.org/10.1016/j.lwt.2021.111344

- Kutlu, N., Pandiselvam, R., Saka, I., Kamiloglu, A., Sahni, P., Kothakota, A. (2021). Impact of different microwave treatments on food texture. Journal of Texture Studies, 53 (6), 709–736. https://doi.org/10.1111/jtxs.12635

- Guzik, P., Kulawik, P., Zając, M., Migdał, W. (2021). Microwave applications in the food industry: an overview of recent developments. Critical Reviews in Food Science and Nutrition, 62 (29), 7989–8008. https://doi.org/10.1080/10408398.2021.1922871

- Araujo, R. G., Rodríguez-Jasso, R. M., Ruíz, H. A., Govea-Salas, M., Pintado, M., Aguilar, C. N. (2021). Recovery of bioactive components from avocado peels using microwave-assisted extraction. Food and Bioproducts Processing, 127, 152–161. https://doi.org/10.1016/j.fbp.2021.02.015

- Akpinar, E. K. (2004). Energy and exergy analyses of drying of red pepper slices in a convective type dryer. International Communications in Heat and Mass Transfer, 31 (8), 1165–1176. https://doi.org/10.1016/j.icheatmasstransfer.2004.08.014

- Kavak Akpinar, E., Midilli, A., Bicer, Y. (2005). Energy and exergy of potato drying process via cyclone type dryer. Energy Conversion and Management, 46 (15-16), 2530–2552. https://doi.org/10.1016/j.enconman.2004.12.008

- Mustaffar, A., Phan, A., Boodhoo, K. (2018). Hybrid heat pipe screw dryer: A novel, continuous and highly energy-efficient drying technology. Chemical Engineering and Processing - Process Intensification, 128, 199–215. https://doi.org/10.1016/j.cep.2018.04.035

- Asghar, M. T., Yusof, Y. A., Mokhtar, M. N., Yaacob, M. E., Ghazali, H. M., Varith, J. et al. (2020). Processing of coconut sap into sugar syrup using rotary evaporation, microwave, and open-heat evaporation techniques. Journal of the Science of Food and Agriculture, 100 (10), 4012–4019. https://doi.org/10.1002/jsfa.10446

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Oleg Burdo, Igor Bezbakh, Mykola Kepin, Alla Burdo, Igor Yevtushenko, Natalya Bahmutian, Lyudmila Phylipova, Dmytro Kharenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.