Design of a combined apparatus for low-temperature processing of confectionery products based on plant-based multicomponent semi-finished products

DOI:

https://doi.org/10.15587/1729-4061.2025.335468Keywords:

plant polycomponent semi-finished products, combined IR device, low-temperature processing, Peltier elements, functional confectionery productsAbstract

The object of this study is the process of low-temperature processing of confectionery products, in particular marshmallows made on the basis of plant polycomponent semi-finished products, taking into account the parameters of infrared heating and preliminary air preparation. The task relates to the lack of effective technologies for low-temperature processing of confectionery products with plant polycomponent semi-finished products to preserve their quality and functionality.

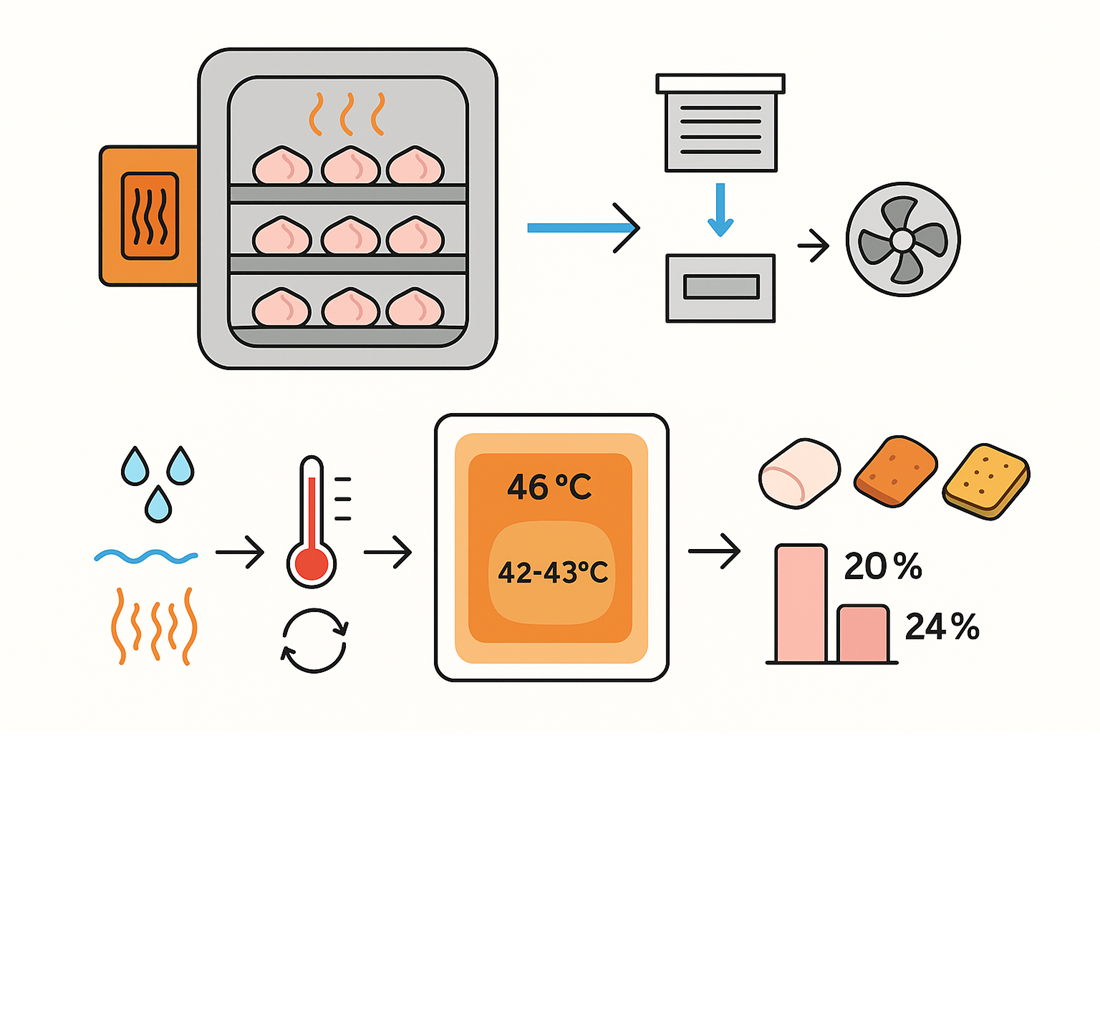

A model of a combined apparatus for low-temperature processing of confectionery products, in particular marshmallows made on the basis of plant polycomponent semi-finished products, is given. The apparatus has a rectangular chamber with rounded edges for uniform heat flow, a film-like resistive electric heater of the radiant type (30…120°C), replaceable functional trays, and an autonomous ventilation system based on Peltier elements. Air is recirculated with preliminary drying and heating up to 45°C.

The uniformity of the heat flux distribution on the receiving surface has been confirmed: the central temperature was 46.0°C, the contour temperature was within 42.0…43.1°C. This thermal regime helps stabilize the structure of confectionery products during low-temperature processing. The experimental process of drying marshmallows demonstrates effective dehydration: classic marshmallows lose up to 20% of moisture in 50 min, marshmallows with plant polycomponent semi-finished products – up to 22% in 70 min, and marshmallows with plant polycomponent semi-finished products and amaranth – up to 24% in 80 min. The data indicate the need to extend the drying time of samples with plant ingredients because of their increased hydrophilicity.

Sensory evaluation has confirmed the high quality of the finished confectionery products. The highest indicators were obtained for marshmallows with RPN and amaranth (aroma – 5.0; taste – 4.9; structure – 4.8). The designed structure became the basis for assembling a device with high-quality low-temperature processing of confectionery products. The device is suitable for the production of pastilles, snacks, bakery products, and drying of plant raw materials in pharmaceuticals and cosmetics

References

- Li, S., Wang, Y., Xue, Z., Jia, Y., Li, R., He, C., Chen, H. (2021). The structure-mechanism relationship and mode of actions of antimicrobial peptides: A review. Trends in Food Science & Technology, 109, 103–115. https://doi.org/10.1016/j.tifs.2021.01.005

- Żołnierczyk, A. K., Pachura, N., Bąbelewski, P., Taghinezhad, E. (2023). Sensory and Biological Activity of Medlar (Mespilus germanica) and Quince ‘Nivalis’ (Chaenomeles speciosa): A Comperative Study. Agriculture, 13 (5), 922. https://doi.org/10.3390/agriculture13050922

- Zahorulko, A., Zagorulko, A., Yancheva, M., Savinok, O., Yakovets, L., Zhelievа, T. et al. (2023). Improving the production technique of meat chopped semi-finished products with the addition of dried semi-finished product with a high degree of readiness. Eastern-European Journal of Enterprise Technologies, 2 (11 (122)), 6–14. https://doi.org/10.15587/1729-4061.2023.276249

- Zahorulko, A., Cherevko, O., Zagorulko, A., Yancheva, M., Budnyk, N., Nakonechna, Y. et al. (2021). Design of an apparatus for low-temperature processing of meat delicacies. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 6–12. https://doi.org/10.15587/1729-4061.2021.240675

- Huang, D., Yang, P., Tang, X., Luo, L., Sunden, B. (2021). Application of infrared radiation in the drying of food products. Trends in Food Science &Technology, 110, 765–777. https://doi.org/10.1016/j.tifs.2021.02.039

- Tikhomirov, D., Khimenko, A., Kuzmichev, A., Budnikov, D., Bolshev, V. (2024). Raising the Drying Unit for Fruits and Vegetables Energy Efficiency by Application of Thermoelectric Heat Pump. Agriculture, 14 (6), 922. https://doi.org/10.3390/agriculture14060922

- Kumar, C., Karim, M. A., Joardder, M. U. H. (2014). Intermittent drying of food products: A critical review. Journal of Food Engineering, 121, 48–57. https://doi.org/10.1016/j.jfoodeng.2013.08.014

- Ramachandran, R. P., Nadimi, M., Cenkowski, S., Paliwal, J. (2024). Advancement and Innovations in Drying of Biopharmaceuticals, Nutraceuticals, and Functional Foods. Food Engineering Reviews, 16 (4), 540–566. https://doi.org/10.1007/s12393-024-09381-7

- Zahorulko, A., Zagorulko, A., Yancheva, M., Ponomarenko, N., Tesliuk, H., Silchenko, E. et al. (2020). Increasing the efficiency of heat and mass exchange in an improved rotary film evaporator for concentration of fruit-and-berry puree. Eastern-European Journal of Enterprise Technologies, 6 (8 (108)), 32–38. https://doi.org/10.15587/1729-4061.2020.218695

- Shirkole, S. S., Mujumdar, A. S., Raghavan, G. S. V.; Jafari, S. M., Malekjani, N. (Eds.) (2023). Drying of foods: Principles, practices and new developments. Drying Technology in Food Processing. Woodhead Publishing, 3–29. https://doi.org/10.1016/b978-0-12-819895-7.00020-1

- Cansu, Ü. (2024). Utilization of Infrared Drying as Alternative to Spray- and Freeze-Drying for Low Energy Consumption in the Production of Powdered Gelatin. Gels, 10 (8), 522. https://doi.org/10.3390/gels10080522

- Aboud, S. A., Altemimi, A. B., R. S. Al-HiIphy, A., Yi-Chen, L., Cacciola, F. (2019). A Comprehensive Review on Infrared Heating Applications in Food Processing. Molecules, 24 (22), 4125. https://doi.org/10.3390/molecules24224125

- Riadh, M. H., Ahmad, S. A. B., Marhaban, M. H., Soh, A. C. (2015). Infrared Heating in Food Drying: An Overview. Drying Technology, 33 (3), 322–335. https://doi.org/10.1080/07373937.2014.951124

- Leong, S. Y., Oey, I. (2022). Application of Novel Thermal Technology in Foods Processing. Foods, 11 (1), 125. https://doi.org/10.3390/foods11010125

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

- Overcoming common freeze drying challenges. GEA. Available at: https://www.gea.com/ru/expert-knowledge/overcoming-common-freeze-drying-challenges-ebook/

- Kiranoudis, C. T., Maroulis, Z. B., Marinos-Kouris, D., Tsamparlis, M. (1997). Design of tray dryers for food dehydration. Journal of Food Engineering, 32 (3), 269–291. https://doi.org/10.1016/s0260-8774(97)00010-1

- Boruah, A., Nath, P. C., Nayak, P. K., Bhaswant, M., Saikia, S., Kalita, J. et al. (2025). Impact of Tray and Freeze Drying on Physico-Chemical and Functional Properties of Underutilized Garcinia lanceifolia (Rupohi thekera). Foods, 14 (4), 705. https://doi.org/10.3390/foods14040705

- Poole, S. F., Amin, O. J., Solomon, A., Barton, L. X., Campion, R. P., Edmonds, K. W. et al. (2024). Thermally stable Peltier controlled vacuum chamber for electrical transport measurements. Review of Scientific Instruments, 95 (3). https://doi.org/10.1063/5.0186155

- Fernandes, P., Gaspar, P. D., Silva, P. D. (2023). Peltier Cell Integration in Packaging Design for Minimizing Energy Consumption and Temperature Variation during Refrigerated Transport. Designs, 7 (4), 88. https://doi.org/10.3390/designs7040088

- Tsotsas, E., Mujumdar, A. S. (Eds.) (2014). Modern Drying Technology. https://doi.org/10.1002/9783527631704

- Múnera-Tangarife, R. D., Solarte-Rodríguez, E., Vélez-Pasos, C., Ochoa-Martínez, C. I. (2021). Factors Affecting the Time and Process of CMC Drying Using Refractance Window or Conductive Hydro-Drying. Gels, 7 (4), 257. https://doi.org/10.3390/gels7040257

- Freeze drying. Wikipedia. Available at: https://en.wikipedia.org/wiki/Freeze_drying

- Zang, Z., Huang, X., He, C., Zhang, Q., Jiang, C., Wan, F. (2023). Improving Drying Characteristics and Physicochemical Quality of Angelica sinensis by Novel Tray Rotation Microwave Vacuum Drying. Foods, 12 (6), 1202. https://doi.org/10.3390/foods12061202

- Voronenko, I., Klymenko, N., Nahorna, O. (2022). Challenges to Ukraine’s Innovative Development in a Digital Environment. Management and Production Engineering Review, 13 (4), 48–58. https://doi.org/10.24425/mper.2022.142394

- Zavidna, L., Trut, O., Slobodianiuk, O., Voronenko, I., Vartsaba, V. (2022). Application of Anti-Crisis Measures for the Sustainable Development of the Regional Economy in the Context of Doing Local Business in a Post-COVID Environment. International Journal of Sustainable Development and Planning, 17 (5), 1685–1693. https://doi.org/10.18280/ijsdp.170535

- Zahorulko, A. M., Zahorulko, O. Ye. (2021). Pat. No. 149981 UA. Plivkopodibnyi rezystyvnyi elektronahrivach vyprominiuiuchoho typu. MPK H05B 3/36, B01D 1/22, G05D 23/19. No. u202102839; declareted: 28. 05.2021; published: 23.12.2021, Bul. No. 51, 4.

- Shevchenko, A., Fursik, O., Drobot, V., Shevchenko, O. (2023). The Use of Wastes from the Flour Mills and Vegetable Processing for the Enrichment of Food Products. Bioconversion of Wastes to Value-Added Products. CRC Press, 1–35. https://doi.org/10.1201/9781003329671-1

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Andrii Zahorulko, Iryna Voronenko, Mykola Nikolaienko, Sofiia Minenko, Nataliia Ponomarenko, Ruslan Zakharchenko, Eldar Ibaiev , Nataliia Tytarenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.