Development and optimization of technology of soft cheese production from camel milk

DOI:

https://doi.org/10.15587/1729-4061.2025.335523Keywords:

camel milk, soft cheese, coagulation temperature, coagulant dose, cheese yieldAbstract

The object of this study is the soft cheese production from camel milk (Camelus dromedarius), with a specific focus on curd formation and the structural and quality characteristics of the final product.

The study addresses a key problem, namely it’s the weak gelation and unstable curd structure of camel milk, resulting from its atypical protein composition, which complicates its use in cheese making. The main task was to identify optimal values of coagulant dose and coagulation temperature to enhance both cheese yield and quality.

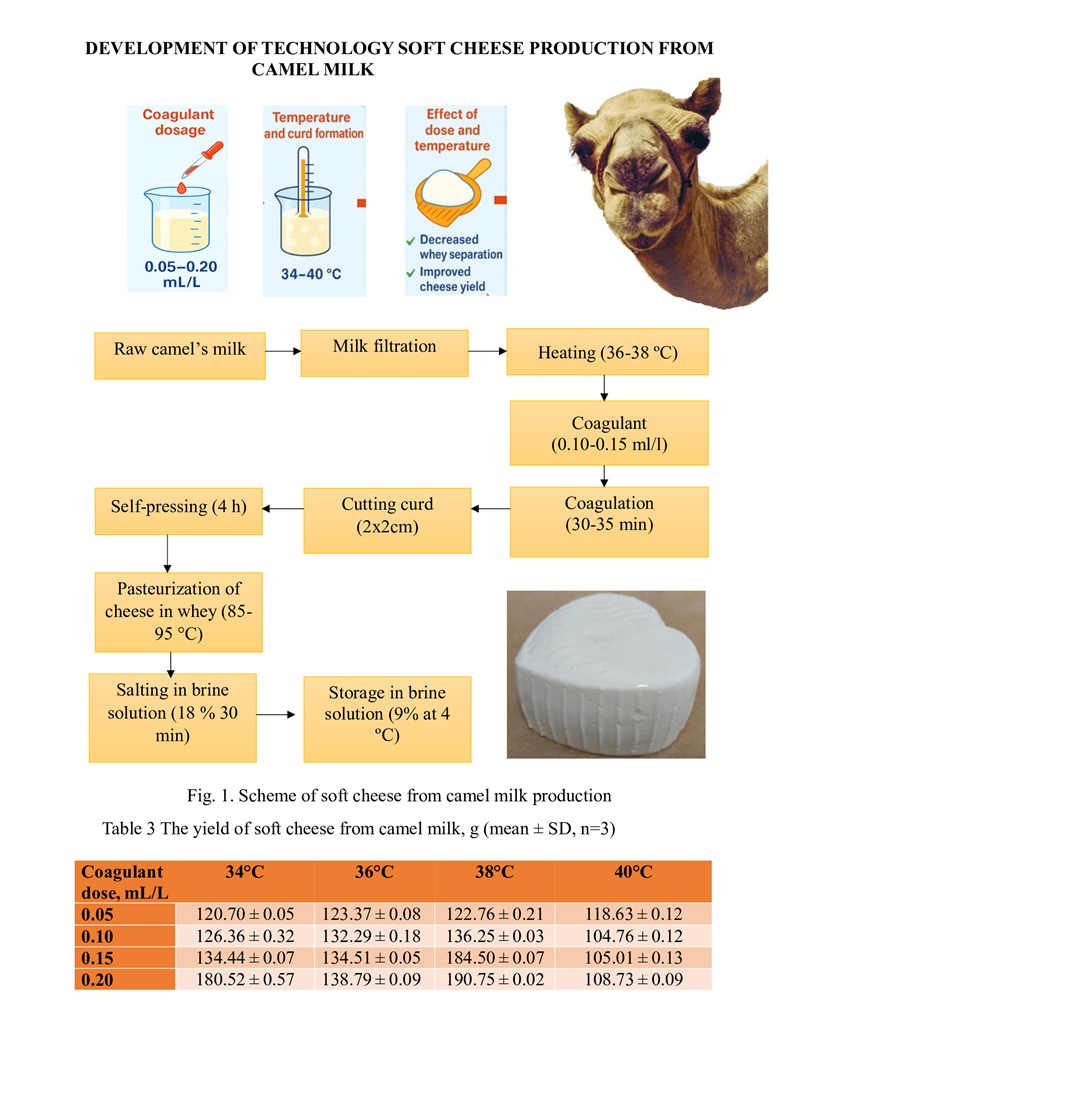

Experimental studies evaluated the effects of ChyMax® M 1000 at doses of 0.05–0.20 ml/l and coagulation temperatures of 34–40°C on key technological indicators such as yield, syneresis, moisture retention, and textural attributes. Both factors significantly influenced the development of curd and final product quality. The most favorable results were obtained at a coagulant dose of 0.10–0.15 ml/l and a coagulation temperature of 36–38°C. Under these conditions, cheese yield reached up to 184.5 g/l, with improved moisture content (up to 60.5%), moderate syneresis, and enhanced textural characteristics. These outcomes are attributed to increased proteolytic activity and improved gel matrix formation at the optimal conditions. The key distinguishing feature of the results is the identified balance of coagulant dose and temperature, which led to stable curd structure and higher cheese yield.

A technological scheme for the soft cheese production from camel milk was developed, offering potential for industrial-scale application. The proposed process is suitable for dairy enterprises seeking to diversify their product range with functional and regionally adapted soft cheeses based on camel milk

References

- Bilal, Z., Amutova, F., Kabdullina, Z., Utemuratova, D., Kondybayev, A., Akhmetsadykova, S. et al. (2025). Study of biological safety of camel milk after treatment with different antibiotics. PLOS One, 20 (4), e0321807. https://doi.org/10.1371/journal.pone.0321807

- Konuspayeva, G., Camier, B., Aleilawi, N., Al‐Shumeimyri, M., Al‐Hammad, K., Algruin, K. et al. (2016). Manufacture of dry‐ and brine‐salted soft camel cheeses for the camel dairy industry. International Journal of Dairy Technology, 70 (1), 92–101. https://doi.org/10.1111/1471-0307.12319

- Alia, O. A. E., Zine-Eddine, Y., Ajbli, N., Kzaiber, F., Oussama, A., Boutoial, K. (2023). Optimization of camel milk coagulation: the use of coagulants of microbiological and plant origin. Acta Scientiarum Polonorum Technologia Alimentaria, 22 (1), 81–91. https://doi.org/10.17306/j.afs.2023.1106

- Gabrilyants, E., Alibekov, R. (2024). The influence of lactic acid bacteria on a number of aspects of the process of producing cheese from camel milk. Bulletin of the L. N. Gumilyov Eurasian National University. Bioscience Series, 149 (4), 63–74. https://doi.org/10.32523/2616-7034-2024-149-4-63-74

- Mihretie, Y., Tadesse, N., Amakelew, S., Fikru, S. (2018). Cheese production from camel milk using lemon juice as a coagulant. Journal of Environmental and Agricultural Sciences, 17, 11–19. https://doi.org/10.13140/RG.2.2.27716.37760

- Omrani, A., Sboui, A., Hannachi, H., Hamouda, M., Dbara, M., Hammadi, M. et al. (2024). Optimisation of soft camel cheese production coagulated with green carob extract using response surface methodology: Yield, physicochemical, microbial, sensorial, and rheological properties. International Journal of Dairy Technology, 77 (4), 1159–1170. https://doi.org/10.1111/1471-0307.13118

- Konuspayeva, G., Camier, B., Gaucheron, F., Faye, B. (2014). Some parameters to process camel milk into cheese. Emirates Journal of Food and Agriculture, 26 (4), 354. https://doi.org/10.9755/ejfa.v26i4.17277

- Al-zoreky, N. S., Almathen, F. S. (2021). Using recombinant camel chymosin to make white soft cheese from camel milk. Food Chemistry, 337, 127994. https://doi.org/10.1016/j.foodchem.2020.127994

- IDF Standard 157: 2007/ISO 11815 Milk – Determination of total milk-clotting activity of bovine rennets (2007). ISO and IDF. Available at: https://cdn.standards.iteh.ai/samples/43876/16e0de8955e74c1fbc8f912e96c85b7b/ISO-11815-2007.pdf

- Official Methods of Analysis (1997). Arlington: Association of Official Analytical Chemists.

- Kamal, M., Foukani, M., Karoui, R. (2017). Effects of heating and calcium and phosphate mineral supplementation on the physical properties of rennet-induced coagulation of camel and cow milk gels. Journal of Dairy Research, 84 (2), 220–228. https://doi.org/10.1017/s0022029917000152

- Panthi, R. R., Kelly, A. L., Sheehan, J. J., Bulbul, K., Vollmer, A. H., & McMahon, D. J. (2019). Influence of protein concentration and coagulation temperature on rennet-induced gelation characteristics and curd microstructure. Journal of Dairy Science, 102(1), 177–189. https://doi.org/10.3168/jds.2018-15039

- Fox, P. F., McSweeney, P. L. H. (Eds.) (2013). Advanced Dairy Chemistry, Volume 1A: Proteins: Basic Aspects. Springer. https://doi.org/10.1007/978-1-4614-4714-6

- Walstra, P., Walstra, P., Wouters, J. T. M., Geurts, T. J. (2005). Dairy Science and Technology. Boca Raton: CRC Press, 808. https://doi.org/10.1201/9781420028010

- Warncke, M., Keienburg, S., Kulozik, U. (2021). Cold-Renneted Milk Powders for Cheese Production: Impact of Casein/Whey Protein Ratio and Heat on the Gelling Behavior of Reconstituted Rennet Gels and on the Survival Rate of Integrated Lactic Acid Bacteria. Foods, 10 (7), 1606. https://doi.org/10.3390/foods10071606

- Bekele, B., Hansen, E. B., Eshetu, M., Ipsen, R., Hailu, Y. (2019). Effect of starter cultures on properties of soft white cheese made from camel (Camelus dromedarius) milk. Journal of Dairy Science, 102 (2), 1108–1115. https://doi.org/10.3168/jds.2018-15084

- Mbye, M., Ayyash, M., Abu-Jdayil, B., Kamal-Eldin, A. (2022). The Texture of Camel Milk Cheese: Effects of Milk Composition, Coagulants, and Processing Conditions. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.868320

- Madadlou, A., Khosroshahi, A., Mousavi, S. M., Djome, Z. E. (2006). Microstructure and Rheological Properties of Iranian White Cheese Coagulated at Various Temperatures. Journal of Dairy Science, 89 (7), 2359–2364. https://doi.org/10.3168/jds.s0022-0302(06)72308-6

- Bunka, F., Pachlová, V., Nenutilová, L. (2013). Texture Properties of Dutch-Type Cheese as a Function of Its Location and Ripening. International Journal of Food Properties, 16 (5), 1016–1027. https://doi.org/10.1080/10942912.2011.575496

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Eleonora Gabrilyants, Aidana Utebaeva, Ravshanbek Alibekov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.