Design of a shelf pneumatic classifier for separating a polydisperse mixture of granulated superphosphate

DOI:

https://doi.org/10.15587/1729-4061.2022.267037Keywords:

granular fertilizers, pneumatic classifier, energy consumption, energy efficiency, fine fraction, carryover, energy savingAbstract

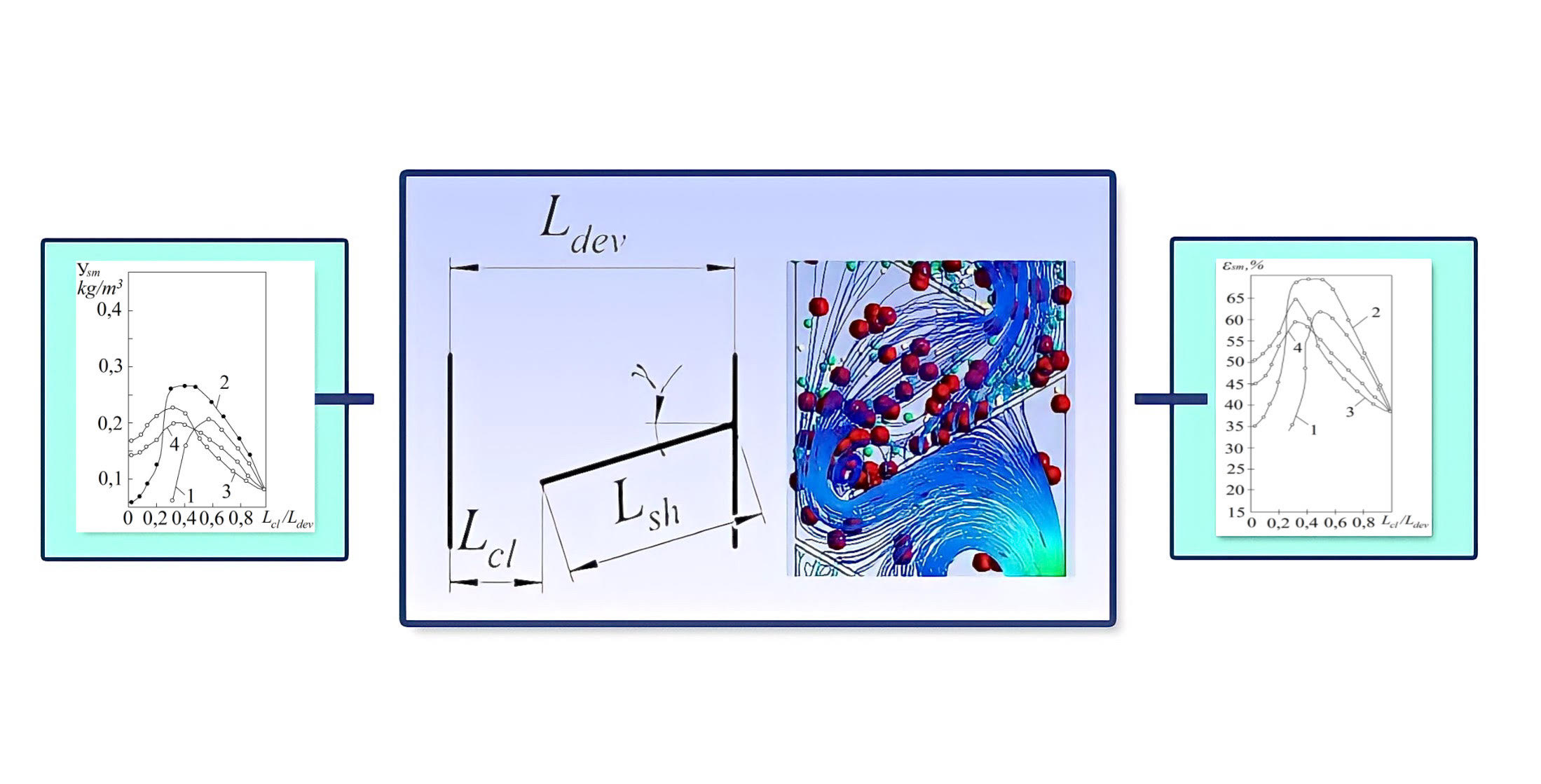

The object of this study is a polydisperse mixture of granular superphosphate. It is emphasized that existing technologies of granulation and processing of granules lead to the formation of dusty fractions of small particles. The content of small fractions in the finished product should be minimal and, in connection with this problem, the task is to remove small particles from the mixture. The purpose of the current experimental study is to classify a polydisperse mixture of granular superphosphate in a pneumatic classifier. The device includes an inclined perforated shelf with an unloading space between its end and the wall of the apparatus. It has been experimentally revealed that the maximum efficiency of extraction into the entrainment of small particles is achieved with a width of the discharge space equal to 0.5 of the length of the cross-sectional side of the apparatus; the degree of perforation of the shelf is 5 %; the angle of inclination of the shelf is 25–30°; the speed of the gas flow in the free section of the apparatus is 3.7 m/s. It is shown that the degree of extraction into the entrainment of a small fraction less than 1 mm in size reaches 70–75 %, the content of the small fraction in the carry-over is 96–98 %, and the large fraction is less than 5 %. By processing experimental data, an empirical equation was built that makes it possible to determine the concentration of particles in the gas stream for individual fractions of the material. It is shown that due to the implementation of an active aerodynamic weighing mode, the shelf pneumatic classifier works at specific loads for air flow rate less than the typical designs of fluidized bed separators. It is noted that the effective operation of the shelf pneumatic classifier in the production of granular mineral fertilizers is ensured at a productivity of no more than 10–12 t/h. With greater productivity, there is a need to install several devices in the technological line

References

- Giroto, A. S., do Valle, S. F., Guimarães, G. G. F., Molina, A., Reis, H. P. G., Fernandes, D. M. et al. (2020). Tailoring Efficient Materials for NPK All-in-One Granular Fertilization. Industrial & Engineering Chemistry Research, 59 (41), 18387–18395. doi: https://doi.org/10.1021/acs.iecr.0c02985

- Sherkuziev, D. (2021). Simple superphosphate by two-stage acid treatment of phosphate raw materials. IOP Conference Series: Earth and Environmental Science, 939 (1), 012057. doi: https://doi.org/10.1088/1755-1315/939/1/012057

- Fazullin, R. K., Khalitov, R. A., Khuziahmetov, R. K., Matuhin, E. L., Fazullina, A. A. (2020). Granular nitrogen and nitrogen-potassium fertilizers containing sulfur from the spent acid mixture of nitrocellulose production. IOP Conference Series: Materials Science and Engineering, 862 (6), 062034. doi: https://doi.org/10.1088/1757-899x/862/6/062034

- Erro, J., Urrutia, O., Baigorri, R., Fuentes, M., Zamarreño, A. M., Garcia-Mina, J. M. (2016). Incorporation of humic-derived active molecules into compound NPK granulated fertilizers: main technical difficulties and potential solutions. Chemical and Biological Technologies in Agriculture, 3 (1). doi: https://doi.org/10.1186/s40538-016-0071-7

- Otwinowski, H., Krzywanski, J., Urbaniak, D., Wylecial, T., Sosnowski, M. (2021). Comprehensive Knowledge-Driven AI System for Air Classification Process. Materials, 15 (1), 45. doi: https://doi.org/10.3390/ma15010045

- Yu, Y., Wang, L., Liu, J. (2022). Analysis of numerical simulation models for the turbo air classifier. Materialwissenschaft Und Werkstofftechnik, 53 (5), 644–657. doi: https://doi.org/10.1002/mawe.202100130

- Jia, F., Mou, X., Fang, Y., Chen, C. (2021). A New Rotor-Type Dynamic Classifier: Structural Optimization and Industrial Applications. Processes, 9 (6), 1033. doi: https://doi.org/10.3390/pr9061033

- He, Y., Duan, C., Wang, H., Zhao, Y., Tao, D. (2010). Separation of metal laden waste using pulsating air dry material separator. International Journal of Environmental Science & Technology, 8 (1), 73–82. doi: https://doi.org/10.1007/bf03326197

- Pavlenko, I. V., Yukhymenko, M. P., Lytvynenko, A. V., Bocko, J. (2019). Solving the Nonstationary Problem of the Disperse Phase Concentration during the Pneumoclassification Process of Mechanical Mixtures. Journal of Engineering Sciences, 6 (1), F1–F5. doi: https://doi.org/10.21272/jes.2019.6(1).f1

- Banjac, V., Pezo, L., Pezo, M., Vukmirović, Đ., Čolović, D., Fišteš, A., Čolović, R. (2017). Optimization of the classification process in the zigzag air classifier for obtaining a high protein sunflower meal – Chemometric and CFD approach. Advanced Powder Technology, 28 (3), 1069–1078. doi: https://doi.org/10.1016/j.apt.2017.01.013

- Mann, H., Roloff, C., Hagemeier, T., Thévenin, D., Tomas, J. (2017). Model-based experimental data evaluation of separation efficiency of multistage coarse particle classification in a zigzag apparatus. Powder Technology, 313, 145–160. doi: https://doi.org/10.1016/j.powtec.2017.03.003

- Yukhymenko, M., Ostroha, R., Litvinenko, A., Bocko, J. (2017). Estimation of gas flow dustiness in the main pipelines of booster compressor stations. IOP Conference Series: Materials Science and Engineering, 233, 012026. doi: https://doi.org/10.1088/1757-899x/233/1/012026

- Shapiro, M., Galperin, V. (2005). Air classification of solid particles: a review. Chemical Engineering and Processing: Process Intensification, 44 (2), 279–285. doi: https://doi.org/10.1016/j.cep.2004.02.022

- Liu, Z., Xie, Y., Wang, Y., Yu, J., Gao, S., Xu, G. (2012). Tandem fluidized bed elutriator – Pneumatic classification of coal particles in a fluidized conveyer. Particuology, 10 (5), 600–606. doi: https://doi.org/10.1016/j.partic.2012.03.005

- Zhou, E., Shan, Y., Li, L., Shen, F., Byambajav, E., Zhang, B., Shi, C. (2021). Study on the Fluidization Quality Characterization Method and Process Intensification of Fine Coal Separation in a Vibrated Dense Medium Fluidized Bed. ACS Omega, 6 (22), 14268–14277. doi: https://doi.org/10.1021/acsomega.1c01034

- Aziz, M. A. A., Isa, K. Md., Miles, N. J., Rashid, R. A. (2018). Pneumatic jig: effect of airflow, time and pulse rates on solid particle separation. International Journal of Environmental Science and Technology, 16 (1), 11–22. doi: https://doi.org/10.1007/s13762-018-1648-4

- Ambrós, W. M., Sampaio, C. H., Cazacliu, B. G., Conceição, P. N., dos Reis, G. S. (2019). Some observations on the influence of particle size and size distribution on stratification in pneumatic jigs. Powder Technology, 342, 594–606. doi: https://doi.org/10.1016/j.powtec.2018.10.029

- Ambrós, W. M. (2020). Jigging: A Review of Fundamentals and Future Directions. Minerals, 10 (11), 998. doi: https://doi.org/10.3390/min10110998

- Varukha, D. A., Smirnov, V. А., Edl, M., Demianenko, M. M., Yukhymenko, M. P., Pavlenko, I. V., Liaposhchenko, O. O. (2018). Modelling of Separation and Air Classification Processes of Aerodisperse Systems in the Shelving Device. Journal of Engineering Sciences, 5 (1), F5–F9. doi: https://doi.org/10.21272/jes.2018.5(1).f2

- Yukhymenko, M., Artyukhov, A., Ostroha, R., Artyukhova, N., Krmela, J., Bocko, J. (2021). Multistage Shelf Devices with Fluidized Bed for Heat-Mass Transfer Processes: Experimental Studies and Practical Implementation. Applied Sciences, 11 (3), 1159. doi: https://doi.org/10.3390/app11031159

- Ostroha, R., Yukhymenko, M., Yakushko, S., Artyukhov, A. (2017). Investigation of the kinetic laws affecting the organic suspension granulation in the fluidized bed. Eastern-European Journal of Enterprise Technologies, 4 (1 (88)), 4–10. doi: https://doi.org/10.15587/1729-4061.2017.107169

- Yukhymenko, M., Ostroha, R., Lytvynenko, A., Mikhajlovskiy, Y., Bocko, J. (2020). Cooling Process Intensification for Granular Mineral Fertilizers in a Multistage Fluidized Bed Device. Lecture Notes in Mechanical Engineering, 249–257. doi: https://doi.org/10.1007/978-3-030-50491-5_24

- Leva, M. (1951). Elutriation of Fines from Fluidized Systems. Chem. Eng. Prog., 47 (1), 39–45.

- Osberg, G. L., Charlesworth, D. H. (1951). Elutriation in a Fluidized Bed. Chem. Eng. Prog., 47 (11), 566–570.

- Kunii, D., Levenspiel, O. (1969). Entrapment and elutriation from fluidized beds. Journal of Chemical Engineering of Japan, 2 (1), 84–88. doi: https://doi.org/10.1252/jcej.2.84

- Davidson, J. F., Harrison, D. (Eds.) (1985). Fluidization. Academic Press, 733.

- Pemberton, S. T., Davidson, J. F. (1986). Elutriation from fluidized beds – I. Particle ejection from the dense phase into the freeboard. Chemical Engineering Science, 41 (2), 243–251. doi: https://doi.org/10.1016/0009-2509(86)87005-1

- Pemberton, S. T., Davidson, J. F. (1986). Elutriation from fluidized beds – II. Disengagement of particles from gas in the freeboard. Chemical Engineering Science, 41 (2), 253–262. doi: https://doi.org/10.1016/0009-2509(86)87006-3

- Liu, Y.-D., Kimura, S. (1993). Fluidization and entrainment of difficult-to-fluidize fine powdermixed with easy-to-fluidize large particles. Powder Technology, 75 (2), 189–196. doi: https://doi.org/10.1016/0032-5910(93)80081-k

- Rodrı́guez, J. M., Sánchez, J. R., Alvaro, A., Florea, D. F., Estévez, A. M. (2000). Fluidization and elutriation of iron oxide particles. A study of attrition and agglomeration processes in fluidized beds. Powder Technology, 111 (3), 218–230. doi: https://doi.org/10.1016/s0032-5910(99)00292-2

- Monazam, E. R., Breault, R. W., Weber, J., Layfield, K. (2017). Elutriation of fines from binary particle mixtures in bubbling fluidized bed cold model. Powder Technology, 305, 340–346. doi: https://doi.org/10.1016/j.powtec.2016.09.046

- Zenz, F. A., Weil, N. A. (1958). A theoretical-empirical approach to the mechanism of particle entrainment from fluidized beds. AIChE Journal, 4 (4), 472–479. doi: https://doi.org/10.1002/aic.690040417

- Fournol, A. B., Bergougnou, M. A., Baker, C. G. J. (1973). Solids entrainment in a large gas fluidized bed. The Canadian Journal of Chemical Engineering, 51 (4), 401–404. doi: https://doi.org/10.1002/cjce.5450510402

- Malewski, J. (2017). On accuracy of sieve analysis. In Proceedings of the Annual Conference on Aggregates KruszMin’17. Wroclaw, 103–111.

- Sieve analysis. Taking a Close Look at Quality (2009). Retsch GmbH Haan: Haan, 52.

- Green, D. W., Southard, M. Z. (2019). Perry’s Chemical Engineers’ Handbook. McGraw Hill Professional.

- Hartnett, J. P. (Ed.) (1968). Analytical Heat Diffusion Theory. Academic Press. doi: https://doi.org/10.1016/b978-0-12-459756-3.x5001-9

- Yukhimenko, N., Vakal, S. (2016). The exergy analysis of energy efficiency of the technology of granulated phosphorus-potassium fertilizers. Eastern-European Journal of Enterprise Technologies, 5 (6 (83)), 4–10. doi: https://doi.org/10.15587/1729-4061.2016.77182

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Mykola Yukhymenko, Ruslan Ostroha, Jozef Bocko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.