Identification of combustion regularities of fuel mixtures from Azolla biomass, goat manure biochar and goat manure bio-oil for FCC furnace

DOI:

https://doi.org/10.15587/1729-4061.2023.267274Keywords:

FCC, biochar, biomass, goat manure, fuel mixture, combustion, AzollaAbstract

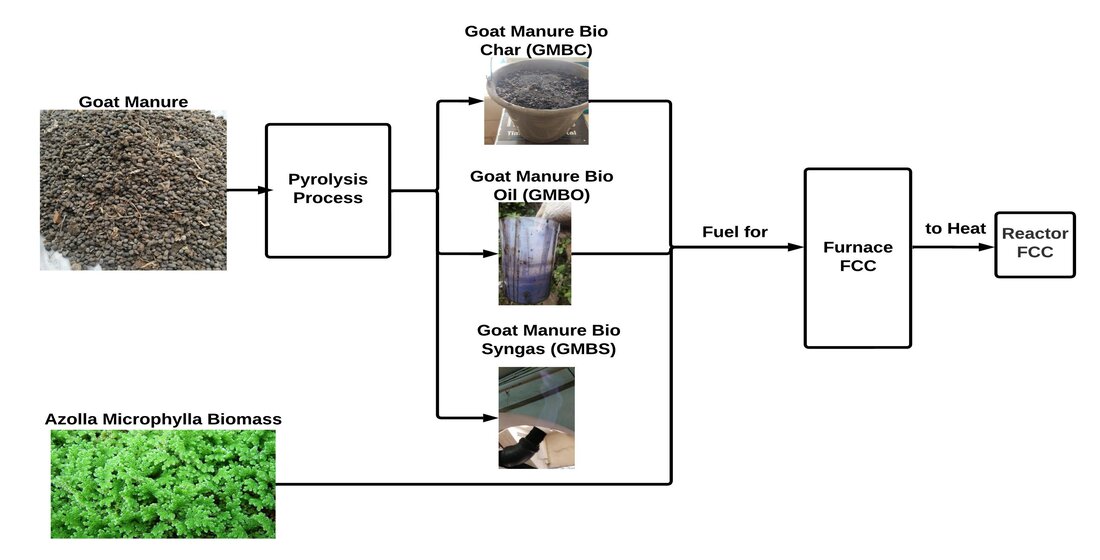

Fluid catalytic cracking (FCC) is a method of cracking vegetable oils into simpler fractions and green fuel oils. One component of the FCC system is the FCC furnace. The FCC furnace is where the combustion process occurs and provides high heat transfer throughout the FCC system, especially for heating the reactor. The reactor temperature is the catalyst cracking temperature. The cracking temperature of the catalyst depends on the feed oil used in the cracking process, such as crude palm oil at 450‒550 °C or crude bio-oil at 300 °C. The fuel for heating an FCC furnace is usually coal. To reduce coal, we use a mixture of Azolla microphylla biomass with biochar and bio-oil from goat manure. The aim of this study was to analyze the mixture of Azolla microphylla biomass with biochar and bio-oil from goat manure to obtain sufficient furnace temperature to heat the FCC reactor, perform analytical calculations to obtain the volume of flue gas formed from the combustion reaction. We conducted two experiments; the first experiment used a mixture of 1 kg of Goat Manure Biochar (GMBC) with 0.5 kg of Azolla microphylla and the second experiment used a mixture of one kg of GMBC with 0.5 kg of Azolla microphylla plus 300 ml of Goat Manure Bio-oil (GMBO). A fuel mixture of one kilogram GMBC with 0.5 kg Azolla is not effective in combustion because the maximum temperature in the furnace is 177 °C but the fuel mixture of one kg GMBC, 0.5 kg Azolla and 300 ml GMBO has a furnace temperature of 472.75 °C, which can heat the stripper up to 313.25 °C so that cracking can occur in the raw bio-oil. Analysis of combustion results showed an increase in total CO2 volume from experiment one and experiment two of 0.966

Supporting Agency

- The authors would like to thank the Directorate of Research and Community Service, Universitas Indonesia, for funding this research project under the PUTI Q3 Program 2022.

References

- Roni, M. S., Chowdhury, S., Mamun, S., Marufuzzaman, M., Lein, W., Johnson, S. (2017). Biomass co-firing technology with policies, challenges, and opportunities: A global review. Renewable and Sustainable Energy Reviews, 78, 1089–1101. doi: https://doi.org/10.1016/j.rser.2017.05.023

- Agbor, E., Zhang, X., Kumar, A. (2014). A review of biomass co-firing in North America. Renewable and Sustainable Energy Reviews, 40, 930–943. doi: https://doi.org/10.1016/j.rser.2014.07.195

- Bhuiyan, A. A., Blicblau, A. S., Islam, A. K. M. S., Naser, J. (2018). A review on thermo-chemical characteristics of coal/biomass co-firing in industrial furnace. Journal of the Energy Institute, 91 (1), 1–18. doi: https://doi.org/10.1016/j.joei.2016.10.006

- Maciejończyk, N., Pełka, G., Luboń, W., Malik, D. (2019). Analysis of the Flue Gas Produced During the Coal and Biomass Co-combustion in a Solid Fuel Boiler. Renewable Energy Sources: Engineering, Technology, Innovation, 239–246. doi: https://doi.org/10.1007/978-3-030-13888-2_23

- Syuriadi, A., Siswantara, A. I., Nurhakim, F. R., Irbah, Y. N., Al Rizky, B., Zulfa, F. A. et al. (2022). Analysis of the effect of biomass variants (fish waste, tamanu waste and duckweed) on the characteristics of syngas, bio oil, and carbon charcoal produced in the pyrolysis process. Eastern-European Journal of Enterprise Technologies, 3 (6 (117)), 41–46. doi: https://doi.org/10.15587/1729-4061.2022.253750

- Sood, A., Uniyal, P. L., Prasanna, R., Ahluwalia, A. S. (2011). Phytoremediation Potential of Aquatic Macrophyte, Azolla. AMBIO, 41 (2), 122–137. doi: https://doi.org/10.1007/s13280-011-0159-z

- Hamdan, H. Z., Houri, A. F. (2021). CO2 sequestration by propagation of the fast-growing Azolla spp. Environmental Science and Pollution Research, 29 (12), 16912–16924. doi: https://doi.org/10.1007/s11356-021-16986-6

- Miranda, A. F., Biswas, B., Ramkumar, N., Singh, R., Kumar, J., James, A. et al. (2016). Aquatic plant Azolla as the universal feedstock for biofuel production. Biotechnology for Biofuels, 9 (1). doi: https://doi.org/10.1186/s13068-016-0628-5

- Golzary, A., Hosseini, A., Saber, M. (2020). Azolla filiculoides as a feedstock for biofuel production: cultivation condition optimization. International Journal of Energy and Water Resources, 5 (1), 85–94. doi: https://doi.org/10.1007/s42108-020-00092-3

- Chouhan, A., Sarma, A. (2013). Critical Analysis of Process Parameters for Bio-oil Production via Pyrolysis of Biomass: A Review. Recent Patents on Engineering, 7 (2), 98–114. doi: https://doi.org/10.2174/18722121113079990005

- Pirbazari, S. M., Norouzi, O., Kohansal, K., Tavasoli, A. (2019). Experimental studies on high-quality bio-oil production via pyrolysis of Azolla by the use of a three metallic/modified pyrochar catalyst. Bioresource Technology, 291, 121802. doi: https://doi.org/10.1016/j.biortech.2019.121802

- Prabakaran, S., Mohanraj, T., Arumugam, A., Sudalai, S. (2022). A state-of-the-art review on the environmental benefits and prospects of Azolla in biofuel, bioremediation and biofertilizer applications. Industrial Crops and Products, 183, 114942. doi: https://doi.org/10.1016/j.indcrop.2022.114942

- Dewanto, M. A. R., Januartrika, A. A., Dewajani, H., Budiman, A. (2017). Catalytic and thermal cracking processes of waste cooking oil for bio-gasoline synthesis. AIP Conference Proceedings. doi: https://doi.org/10.1063/1.4978172

- Makertihartha, I. G. B. N., Fitradi, R. B., Ramadhani, A. R., Laniwati, M., Muraza, O., Subagjo (2020). Biogasoline Production from Palm Oil: Optimization of Catalytic Cracking Parameters. Arabian Journal for Science and Engineering, 45 (9), 7257–7266. doi: https://doi.org/10.1007/s13369-020-04354-4

- Wibowo, S., Efiyanti, L., Pari, G. (2020). Catalytic and Thermal Cracking of Bio-Oil from Oil-Palm Empty Fruit Bunches, in Batch Reactor. Indonesian Journal of Chemistry, 20 (5), 1000. doi: https://doi.org/10.22146/ijc.44076

- Bhuiyan, A. A., Naser, J. (2015). Computational modelling of co-firing of biomass with coal under oxy-fuel condition in a small scale furnace. Fuel, 143, 455–466. doi: https://doi.org/10.1016/j.fuel.2014.11.089

- Zhao, J., Deng, J., Song, J., Shu, C.-M. (2019). Effectiveness of a high-temperature-programmed experimental system in simulating particle size effects on hazardous gas emissions in bituminous coal. Safety Science, 115, 353–361. doi: https://doi.org/10.1016/j.ssci.2019.02.008

- Poddar, S., Sarat Chandra Babu, J. (2021). Modelling and optimization of a pyrolysis plant using swine and goat manure as feedstock. Renewable Energy, 175, 253–269. doi: https://doi.org/10.1016/j.renene.2021.04.120

- Pourkarimi, S., Hallajisani, A., Alizadehdakhel, A., Nouralishahi, A. (2021). Bio-oil production by pyrolysis of Azolla filiculoides and Ulva fasciata macroalgae. Global Journal of Environmental Science and Management, 7 (3), 331–346. doi: https://doi.org/10.22034/GJESM.2021.03.02

- Touray, N., Tsai, W.-T., Chen, H.-R., Liu, S.-C. (2014). Thermochemical and pore properties of goat-manure-derived biochars prepared from different pyrolysis temperatures. Journal of Analytical and Applied Pyrolysis, 109, 116–122. doi: https://doi.org/10.1016/j.jaap.2014.07.004

- Erdogdu, A. E., Polat, R., Ozbay, G. (2019). Pyrolysis of goat manure to produce bio-oil. Engineering Science and Technology, an International Journal, 22 (2), 452–457. doi: https://doi.org/10.1016/j.jestch.2018.11.002

- Type K Thermocouple. Available at: http://www.thermocoupleinfo.com/type-k-thermocouple.htm

- Septiana, R. et al. (2019). Calibration of K-Type Thermocouple and MAX6675 Module with Reference DS18B20 Thermistor Based on Arduino DAQ. Prosiding SNTTM XVIII. Available at: http://prosiding.bkstm.org/prosiding/2019/PTM01.pdf

- Paraschiv, L. S., Serban, A., Paraschiv, S. (2020). Calculation of combustion air required for burning solid fuels (coal / biomass / solid waste) and analysis of flue gas composition. Energy Reports, 6, 36–45. doi: https://doi.org/10.1016/j.egyr.2019.10.016

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Tanwir Ahmad Farhan, Ahmad Indra Siswantara, Ahmad Syihan Auzani, Adi Syuriadi, Candra Damis Widiawaty, Muhammad Hilman Gumelar Syafei, Iwan Susanto

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.