Determining the influence of compressor flow path abrasive wear on the gas turbine engine characteristics

DOI:

https://doi.org/10.15587/1729-4061.2023.275546Keywords:

gas turbine engine, axial compressor, abrasive wear, material erosion, aerodynamic lossesAbstract

The operation of a gas turbine engine (GTE) in a dusty atmosphere leads to wear of the elements of the flowing part and, as a result, to a deterioration in its parameters and characteristics.

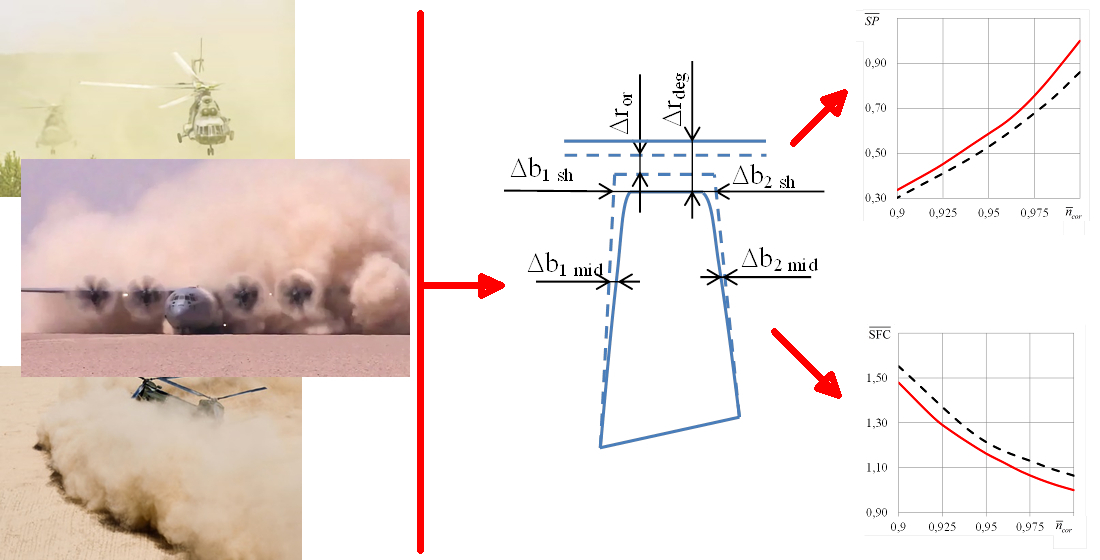

Helicopter and tank gas turbine engines operating in a dusty atmosphere, as well as gas turbine units of compressor stations operated in areas with high dust concentrations, are subjected to the greatest wear. When operating GTE under such conditions, the compressor is subjected to stronger wear. In this regard, the task addressed in this paper is determining the effect of abrasive wear of the compressor on GTE parameters. To this end, a method for calculating the GTE characteristics is built, making it possible to take into account the effect of abrasive wear of the flow path and blade crowns of the compressor.

Underlying the calculation method is a nonlinear mathematical model that makes it possible to describe the processes occurring in individual nodes and in the engine as a whole under stationary modes. A feature of this method is the two-dimensional description of the compressor in the engine system. The method reported here makes it possible to quickly estimate the effect of deviation of the geometric parameters of the flow path from the rated values on the characteristics of the compressor and engine as a whole.

The geometric parameters of the degraded-out axial compressor were simulated on the basis of wear data. The parameters and characteristics of the degraded-out compressor, as well as the gas turbine engine as a whole, were calculated. It was found that with a given wear of the flow path of the compressor, the specific power of the engine decreased by 7.5 % while specific fuel consumption increased by 6.4 %, and the stability margin decreased by 11.1 % compared to the original ones.

The results could be used to analyze and predict the operational efficiency of engines when they operate under conditions of high dustiness.

References

- Dobriakov, Iu. I. (2009) Na zemle pyl est! Problemy razrabotki effektivnogo vertoletnogo GTD. Dvigatel, 62 (2), 4–6.

- D technology helps helicopters land on sand (2011). Available at: https://www.gov.uk/government/news/3d-technology-helps-helicopters-land-on-sand

- Posmotrite, kak voennyi samolet C-130J Super Hercules saditsia i vzletaet priamo v pustyne (2017). Available at: https://carakoom.com/blog/posmotrite-kak-voennyj-samolet-c130j-super-hercules-saditsya-i-vzletaet-pryamo-v-pustyne

- Sallee, G. (1978) Performance deterioration based on existing (historical) data. JT9D jet engine diagnostics program. Ohio: NASA Lewis Research Center Cleveland, 217.

- Sirs, R. C. (1994). The Operation of Gas Turbine Engines in Hot & Sandy Conditions-Royal Air Force Experiences in the Gulf War. AGARD conference proceedings 558: Erosion, Corrosion and Foreign Object Damage Effects in Gas Turbines, Paper No. 2.

- Bojdo, N., Filippone, A. (2019). A Simple Model to Assess the Role of Dust Composition and Size on Deposition in Rotorcraft Engines. Aerospace, 6 (4), 44. doi: https://doi.org/10.3390/aerospace6040044

- Stepanov, G. Iu., Zitcer, I. M. (1986). Inertcionnye vozdukhoochistiteli. Moscow: Mashinostroenie, 184.

- Barone, D., Loth, E., Snyder, P. (2015). Efficiency of an Inertial Particle Separator. Journal of Propulsion and Power, 31 (4), 997–1002. doi: https://doi.org/10.2514/1.b35276

- Przybyła, B. S., Przysowa, R., Zapałowicz, Z. (2020). Implementation of a new inlet protection system into HEMS fleet. Aircraft Engineering and Aerospace Technology, 92 (1), 67–79. doi: https://doi.org/10.1108/aeat-11-2018-0289

- Barone, D., Loth, E., Snyder, P. (2017). Influence of particle size on inertial particle separator efficiency. Powder Technology, 318, 177–185. doi: https://doi.org/10.1016/j.powtec.2017.04.044

- Alqallaf, J., Ali, N., Teixeira, J. A., Addali, A. (2020). Solid Particle Erosion Behaviour and Protective Coatings for Gas Turbine Compressor Blades – A Review. Processes, 8 (8), 984. doi: https://doi.org/10.3390/pr8080984

- Busurgin, A. V., Egorova, A. I., Ershov V. N. (1978). Stend dlia ispytaniia osevykh kompressorov na baze turbovalnogo GTD. Energeticheskoe mashinostroenie, 25, 85–90.

- Evstifeev, A., Kazarinov, N., Petrov, Y., Witek, L., Bednarz, A. (2018). Experimental and theoretical analysis of solid particle erosion of a steel compressor blade based on incubation time concept. Engineering Failure Analysis, 87, 15–21. doi: https://doi.org/10.1016/j.engfailanal.2018.01.006

- Schmucker, J., Schaffler, A. (1994). Performance Deterioration of Axial Compressors Due to Blade Defects. AGARD conference proceedings 558: Erosion, Corrosion and Foreign Object Damage Effects in Gas Turbines, Paper No. 16.

- Dvirnik, Ia. V., Pavlenko, D. V. (2017). Vliianie pylevoi erozii na gazodinamicheskie kharakteristiki osevogo kompressora GTD. Vіsnik dvigunobuduvannia, 1, 56–66.

- Barysheva, E. S., Demin, A. E., Zelenskii, R. L. (2017). Taking into account the blades erosive wear in the modeling of characteristics of the aircraft engine multistage axial compressor. Aerospace Technic and Technology, 6 (141), 58–64.

- Boiko, L. H., Demyn, A. E., Pyzhankova, N. V. (2019). Turboshaft engine thermogasdynamic parameters calculation method based on blade-to blade description of turbomashines. Part II. Stage and multistage compressors parameters determination. Aerospace Technic and Technology, 1 (153), 18–28. doi: https://doi.org/10.32620/aktt.2019.1.02

- Gumerov, A. V., Akmaletdinov, R. G. (2011). Compressor blade erosion modeling. Vestnik Samarskogo gosudarstvennogo aerokosmicheskogo universiteta, 3 (27), 233–239.

- Potapov, V. A., Sanko, A. A. (2020). Performance simulation of multi-stage axial-flow compressor of turbo-shaft engine with account for erosive wear nonlinearity of its blades. Civil Aviation High Technologies, 23 (5), 39–53. doi: https://doi.org/10.26467/2079-0619-2020-23-5-39-53

- Beliaev, D. V., Pikula, E. R., Talyzina, V. S. (1993). Otcenka deformatcii kharakteristik osevogo kompressora v usloviiakh dlitelnoi ekspluatatcii. Izvestiia vuzov. Aviatcionnaia tekhnika, 1, 50–54.

- Li, Y. G. (2009). Gas Turbine Performance and Health Status Estimation Using Adaptive Gas Path Analysis. Proceedings of ASME Turbo Expo 2009, ASME Paper GT2009-59168. doi: https://doi.org/10.1115/gt2009-59168

- Freire, R. L. A., Barbosa, J. R. (2013). Development and Validation of a Methodology for Stationary Gas Turbine Performance Prognostic. Proceedings of ASME Turbo Expo 2013, ASME Paper GT2013-95916. doi: https://doi.org/10.1115/gt2013-95916

- GasTurb Program. Available at: http://www.gasturb.de

- Hosseini, S. H. R., Khaledi, H., Soltani, M. R. (2009). New Model Based Gas Turbine Fault Diagnostics Using 1D Engine Model and Nonlinear Identification Algorithms. Proceedings of ASME Turbo Expo 2009, ASME Paper GT2009-59439. doi: https://doi.org/10.1115/gt2009-59439

- Astrua, P., Cecchi, S., Piola, S., Silingardi, A., Bonzani, F. (2013). Axial Compressor Degradation Effects on Heavy Duty Gas Turbines Overall Performances. Proceedings of ASME Turbo Expo 2013, ASME Paper GT2013-95497. doi: https://doi.org/10.1115/gt2013-95497

- Boiko, L. G., Karpenko, E. L. (2007) Razrabotka metoda rascheta kharakteristik turbovalnogo dvigatelia s poventcovym opisaniem mnogostupenchatogo osevogo kompressora. Vіsnik dvigunobuduvannia, 3, 143–146.

- Boiko, L. G., Karpenko, E. L. (2008). Vliianie ugla ustanovki lopatki vkhodnogo napravliaiushchego apparata na ekspluatatcionnye kharakteristiki gazoturbinnogo dvigatelia. Avіatcіino-kosmіchna tekhnіka і tekhnologіia, 4 (51), 43–50.

- Boiko, L. H., Datsenko, V. A., Pyzhankova, N. V. (2019). Determination of the throttle performances of a turboshaft gte based on the method of mathematical modeling using one and two-dimensional approaches to the compressor parameters calculation. Aerospace Technic and Technology, 7, 21–30. doi: https://doi.org/10.32620/aktt.2019.7.03

- Boiko, L. G., Kislov, O. V. Pizhankova, N. V. (2018). Turboshaft engine thermogasdynamic parameters calculation method blade-to blade description turbomashines based. Part 1.Main equations. Aerospace Technic and Technology, 1 (145), 48–58. doi: https://doi.org/10.32620/aktt.2018.1.05

- Kislov, O., Ambrozhevich, M., Shevchenko, M. (2021). Development of a method to improve the calculation accuracy of specific fuel consumption for performance modeling of air-breathing engines. Eastern-European Journal of Enterprise Technologies, 2 (8 (110)), 23–30. doi: https://doi.org/10.15587/1729-4061.2021.229515

- Boyko, L., Dyomin, A. (2018). Numerical study of flows in axial compressors of aircraft gas-turbine engines. Eastern-European Journal of Enterprise Technologies, 4 (8 (94)), 40–49. doi: https://doi.org/10.15587/1729-4061.2018.139445

- Boiko, L. G., Demin, A. E., Barysheva, E. L., Maksimov, Iu. P., Fesenko, K. V. (2011). Kompleks metodov poverochnogo rascheta osevykh i tcentrobezhnykh kompressorov. Trudy XV Mezhdunarodnoi nauchno-tekhnicheskoi konferentcii po kompressornoi tekhnike, 10.

- Aviamotorostroenie. Internet-muzei rossiiskoi aviatcii. Available at: http://авиару.рф/aviamuseum/dvigateli-i-vooruzhenie/aviamotorostroenie/

- Boyko, L., Datsenko, V., Dyomin, A., Pizhankova, N. (2021). Devising a method for calculating the turboshaft gas turbine engine performance involving a blade-by-blade description of the multi-stage compressor in a two-dimensional setting. Eastern-European Journal of Enterprise Technologies, 4 (8 (112)), 59–66. doi: https://doi.org/10.15587/1729-4061.2021.238538

- Schlichting, H., Gersten, K. (2017). Boundary-layer theory. Berlin: Springer, 805. doi: https://doi.org/10.1007/978-3-662-52919-5

- Aldi, N., Morini, M., Pinelli, M., Spina, P. R., Suman, A., Venturini, M. (2013). Performance Evaluation of Non-Uniformly Fouled Axial Compressor Stages by Means of Computational Fluid Dynamic Analyses. Proceedings of ASME Turbo Expo 2013. ASME Paper GT2013-95580. doi: https://doi.org/10.1115/gt2013-95580

- Haaland, S. E. (1983). Simple and Explicit Formulas for the Friction Factor in Turbulent Pipe Flow. Journal of Fluids Engineering, 105 (1), 89–90. doi: https://doi.org/10.1115/1.3240948

- Strub, R. A., Bonciani, L., Borer, C. J., Casey, M. V., Cole, S. L., Cook, B. B. et al. (1987). Influence of the Reynolds Number on the Performance of Centrifugal Compressors. Journal of Turbomachinery, 109 (4), 541–544. doi: https://doi.org/10.1115/1.3262145

- Syverud, E., Bakken, L. E. (2006). The impact of surface roughness on axial compressor performance deterioration. Proceedings of ASME Turbo Expo 2006. ASME Paper GT2006 – 90004. doi: https://doi.org/10.1115/gt2006-90004

- Lakshminarayana B. (1970). Methods of predicting the tip clearance effects in axial flow turbomachinery. Basic Engineering, 92, 467–482.

- Nechaev, Iu. N., Fedorov, R. M., Kotovskii, V. N., Polev, A. S. (2006). Teoriia aviatcionnykh dvigatelei Ch. 1. Moskva: Izd. VVIA im. N. E. Zhukovskogo, 366.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vadym Datsenko, Ludmila Boyko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.