Improving the technology of aeration of the food system of mousse at horeca enterprises

DOI:

https://doi.org/10.15587/1729-4061.2023.275615Keywords:

collagen hydrolyzate, aerated desserts, mousses, structure-forming agent, dispersion, foamy food systemsAbstract

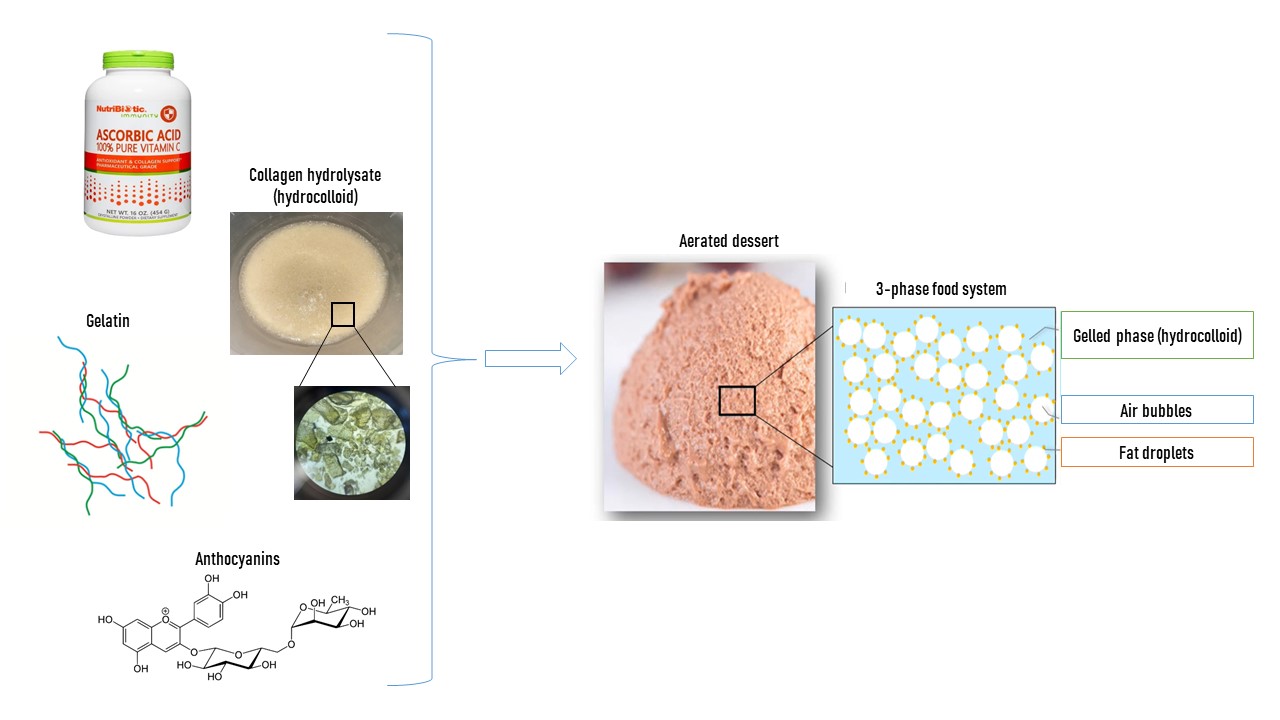

There is an interest in sweet dishes such as aerated desserts, which are gaining popularity among consumers. Raw materials of plant origin, used in the technology of aerated products, are intended mainly to improve their quality characteristics. Especially for enrichment with protein substances, micro and macro elements, vitamins, as well as to obtain a product rich in dietary fiber content. In the segment of aerated dessert products, a distinctive feature of which is the multistage of the production process and the need to use special equipment, technologies involve the use of foam and structure-forming food additives. For the formation of a whipped and stable structure, as well as the addition of surfactants that can cover the surfaces of bubbles and prevent their coalescence, food additives of various origins are used. Therefore, it is relevant to investigate the foaming ability and stability of aerated desserts and improve the technological parameters of the processes or foam structures of desserts. It is necessary to take into account the structural and mechanical properties of aerated dessert products, which are the main characteristics of the quality of aerated desserts. Thus, it is relevant to devise technologies for aerated desserts and food additives in their composition, which will serve as a stabilizing agent, as well as a dietary supplement.

A recipe for aerated dessert – mousse based on fermented milk cheese with the introduction of a complex additive into the recipe – was developed. The optimal amount of food additive in the composition of aerated dessert, which is 3 % of the recipe composition, has been established, which will ensure the stability of the food system of aerated products, in particular mousses. The influence of the additive on the structural and mechanical properties of the food system of dessert has been investigated.

The experimental data could be used for improving technologies for the production of aerated desserts.

References

- Voznenko, M. A., Bondarenko, I. I., Yatsenko, B. О., Nyemirich, O. V. (2016). Technological aspects of the manufacture of whipped artichoke powder. Scientific Messenger of LNU of Veterinary Medicine and Biotechnologies. Series: Food Technologies, 18 (2), 32–36. doi: https://doi.org/10.15421/nvlvet6806

- Munk, M. B., Erichsen, H. R., Andersen, M. L. (2014). The effects of low-molecular-weight emulsifiers in O/W-emulsions on microviscosity of non-solidified oil in fat globules and the mobility of emulsifiers at the globule surfaces. Journal of Colloid and Interface Science, 419, 134–141. doi: https://doi.org/10.1016/j.jcis.2013.12.036

- Petrut, R. F., Danthine, S., Blecker, C. (2016). Assessment of partial coalescence in whippable oil-in-water food emulsions. Advances in Colloid and Interface Science, 229, 25–33. doi: https://doi.org/10.1016/j.cis.2015.12.004

- Zhao, Q., Liu, D., Long, Z., Yang, B., Fang, M., Kuang, W., Zhao, M. (2014). Effect of sucrose ester concentration on the interfacial characteristics and physical properties of sodium caseinate-stabilized oil-in-water emulsions. Food Chemistry, 151, 506–513. doi: https://doi.org/10.1016/j.foodchem.2013.11.113

- Cardarelli, H. R., Aragon-Alegro, L. C., Alegro, J. H. A., de Castro, I. A., Saad, S. M. I. (2008). Effect of inulin and Lactobacillus paracasei on sensory and instrumental texture properties of functional chocolate mousse. Journal of the Science of Food and Agriculture, 88 (8), 1318–1324. doi: https://doi.org/10.1002/jsfa.3208

- Nechaev, A. P., Traubenberg, S. E., Kochetkova, A. A. (2001). Pischevaya khimiya. Sankt-Peterburg: GIORD, 592.

- Dziuba, N. A. (2022). Determination of pharmacological properties of the hydrolyzate of the colleague. Таuridа Scientific Herald. Series: Technical Sciences, 1, 86–95. doi: https://doi.org/10.32851/tnv-tech.2022.1.10

- Sung, W.-C., Chen, Z.-Y. (2014). UV treatment and γ irradiation processing on improving porcine and fish gelatin and qualities of their premix mousse. Radiation Physics and Chemistry, 97, 208–211. doi: https://doi.org/10.1016/j.radphyschem.2013.11.038

- Plekhanova, E. A., Bannikova, A. V., Ptichkina, N. M. (2013). Razrabotka tekhnologii i retseptur molochnykh desertov dieticheskogo naznacheniya. Tekhnika i tekhnologiya pischevykh proizvodstv, 3, 53–57.

- Xavier-Santos, D., Bedani, R., Perego, P., Converti, A., Saad, S. M. I. (2019). L. acidophilus La-5, fructo-oligosaccharides and inulin may improve sensory acceptance and texture profile of a synbiotic diet mousse. LWT, 105, 329–335. doi: https://doi.org/10.1016/j.lwt.2019.02.011

- Herremans, E., Bongaers, E., Estrade, P., Gondek, E., Hertog, M., Jakubczyk, E. et al. (2013). Microstructure–texture relationships of aerated sugar gels: Novel measurement techniques for analysis and control. Innovative Food Science & Emerging Technologies, 18, 202–211. doi: https://doi.org/10.1016/j.ifset.2013.02.003

- Vladisavljević, G. T., Wang, B., Dragosavac, M. M., Holdich, R. G. (2014). Production of food-grade multiple emulsions with high encapsulation yield using oscillating membrane emulsification. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 458, 78–84. doi: https://doi.org/10.1016/j.colsurfa.2014.05.011

- Patel, P., Parekh, T., Subhash, R. (2008). Development of Probiotic and Synbiotic Chocolate Mousse: A Functional Food. Biotechnology(Faisalabad), 7 (4), 769–774. doi: https://doi.org/10.3923/biotech.2008.769.774

- Gomez-Betancur, A. M., Carmona-Tamayo, R., Jaimes-Jaimes, J., Casanova-Yepes, H., Torres-Oquendo, J. D. (2020). Optimisation of yogurt mousse dairy protein levels: a rheological, sensory, and microstructural study. International Food Research Journal, 27 (6), 1076–1086. Available at: https://myjurnal.mohe.gov.my/filebank/published_article/101125/11.pdf

- Duquenne, B., Vergauwen, B., Capdepon, C., Boone, M. A., De Schryver, T., Van Hoorebeke, L. et al. (2016). Stabilising frozen dairy mousses by low molecular weight gelatin peptides. Food Hydrocolloids, 60, 317–323. doi: https://doi.org/10.1016/j.foodhyd.2016.04.001

- Panji, D. D, Octaviany, V., Gusnandi, D. (2019). Utilization of Jackfruit as a Substitute for Sugar and Vegetable Fat in Mousse. e-Proceeding of Applied Science, 5 (3), 2785.

- Aragon-Alegro, L. C., Alarcon Alegro, J. H., Roberta Cardarelli, H., Chih Chiu, M., Isay Saad, S. M. (2007). Potentially probiotic and synbiotic chocolate mousse. LWT - Food Science and Technology, 40 (4), 669–675. doi: https://doi.org/10.1016/j.lwt.2006.02.020

- Jiang, J., Jin, Y., Liang, X., Piatko, M., Campbell, S., Lo, S. K., Liu, Y. (2018). Synergetic interfacial adsorption of protein and low-molecular-weight emulsifiers in aerated emulsions. Food Hydrocolloids, 81, 15–22. doi: https://doi.org/10.1016/j.foodhyd.2018.02.038

- Nykyforov, R. P. (2016). Pozrobka tekhnolohiyi aerovanoi desertnoi produktsiyi na osnovi vtorynnoi molochnoi syrovyny. Obladnannia ta tekhnolohiyi kharchovykh vyrobnytstv, 34, 5–13.

- Rogov, I. V., Antipova, L. V., Dunchenko, N. I. et al. (2000). Khimiya pischi. Kn. 1. Belki: struktura, funktsii, rol' v pitanii. Moscow: Kolos, 384.

- Nikiforov, R. P., Korshunova, A. F. (2012). Obosnovanie sposoba polucheniya polufabrikata na osnove belkov obezzhirennogo moloka s povyshennymi poverkhnostno aktivnymi svoystvami. Tekhnicheskie nauki – Tekhnologii prodovol'stvennykh tovarov.

- Agarkova, E. Yu. (2020). Foam-forming properties of whey proteins hydrolysates. Bulletin of KSAU, 8, 179–185. doi: https://doi.org/10.36718/1819-4036-2020-8-179-185

- Titov, E. I., Ionova, I. I., Krasnova, I. S., Volokitina, Z. V., Kozlov, N. S. (2018). Strukturno-mekhanicheskie pokazateli kislomolochnykh produktov s gidrolizatom belka iz kozhi ryb. Voprosy pitaniya, 87 (5), 243–244.

- Arvanitoyannis, I. S., Kassaveti, A. (2008). Fish industry waste: treatments, environmental impacts, current and potential uses. International Journal of Food Science & Technology, 43 (4), 726–745. doi: https://doi.org/10.1111/j.1365-2621.2006.01513.x

- Karim, A. A., Bhat, R. (2009). Fish gelatin: properties, challenges, and prospects as an alternative to mammalian gelatins. Food Hydrocolloids, 23 (3), 563–576. doi: https://doi.org/10.1016/j.foodhyd.2008.07.002

- Horalchuk, A. B. (2016). Naukove obgruntuvannia tekhnolohiy napivfabrykativ zbyvnykh dlia kulinarnoi ta kondyterskoi produktsiyi z polifaznoiu strukturoiu. Kharkiv: KhDUKhT, 42.

- Buchheim, W. Barlord, N. M., Krog, N. (1985). Relation between microstructure, destabilization phenomena and rheological properties of whippable emulsions. Food Microstruct, 4, 221–232. Available at: https://digitalcommons.usu.edu/cgi/viewcontent.cgi?article=1111&context=foodmicrostructure

- Premixes for Mousses and other Aerated Desserts. Available at: https://www.silverson.com/us/resource-library/application-reports/premixes-for-mousses-and-other-aerated-desserts

- van Aken, G. A. (2001). Aeration of emulsions by whipping. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 190 (3), 333–354. doi: https://doi.org/10.1016/s0927-7757(01)00709-9

- Zdobnov, A. I., Tsyganenko, V. A. (2013). Sbornik retseptur blyud i kulinarnykh izdeliy: Dlya predpriyatiy obschestv. Pitaniya. Kyiv: Ariy, 680. Available at: https://ru.djvu.online/file/g7fiRO4rWdod6

- Baziwane, D., He, Q. (2003). Gelatin: The Paramount Food Additive. Food Reviews International, 19 (4), 423–435. doi: https://doi.org/10.1081/fri-120025483

- Se-Kwon, K., Yong-Tae, K., Hee-Guk, B., Pyo-Jam, P., Hisashi, I. (2001). Purification and characterization of antioxidative peptides from bovine skin. Journal of Biochemistry and Molecular Biology, 34 (3), 219–224.

- Zhang, Z., Li, G., Shi, B. (2006). Physicochemical properties of collagen, gelatin and collagen hydrolysate derived from bovine limed split wastes. Journal of the Society of Leather Technologists and Chemists, 90, 23–29.

- Dzyuba, N., Bilenka, I., Palvashova, A., Zemlyakova, E. (2017). Study into collagen hydrolyzate applicability as a structure forming agent. Eastern-European Journal of Enterprise Technologies, 5 (11 (89)), 10–17. doi: https://doi.org/10.15587/1729-4061.2017.110498

- Burdo, A. K., Dziuba, N. A., Zemliakova, O. V. (2016). Metodychni vkazivky do vykonannia laboratornykh robit z kursu «Teoretychni osnovy kharchovykh tekhnolohiy» dlia studentiv napriamu pidhotovky 6.051701 «Kharchovi tekhnolohiyi ta inzheneriya» dennoi ta zaochnoi form navchannia. Odesa: ONAKhT, 48.

- Oliinyk, M., Dzyuba, N., Stepanova, V. (2021). Designing Formulation for Aerated Desserts for the HoReCa Field. Innovative Biosystems and Bioengineering, 5 (1), 47–60. doi: https://doi.org/10.20535/ibb.2021.5.1.216258

- Telezhenko, L. M., Kushnir, N. A. (2013). Pat. No. 79357 UA. Process for producing collagen preparation. No. u201209751; declareted: 13.08.2012; published: 25.04.2013, Bul. No. 8. Available at: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=185998

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Nadya Dzyuba, Mariia Oliinyk, Iryna Kalugina, Svitlana Poplavska, Yevhenii Bortnykov, Svitlana Zakharova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.