Improving printed products manufacturing technology using 3D printing

DOI:

https://doi.org/10.15587/1729-4061.2023.275913Keywords:

printing technologies, 3D printing, printed products, graphic images, font size, text information, binding, examination method, layer-by-layer deposition, ABS plasticAbstract

The aim of the paper is to analyze the state of the printing industry in the current conditions, learn reproduction technologies on non-absorbent surfaces, and study modern technological processes of obtaining products based on 3D printing, which is the research object. The problem lies in the lack of general recommendations for using the above technology to produce printed products or their elements.

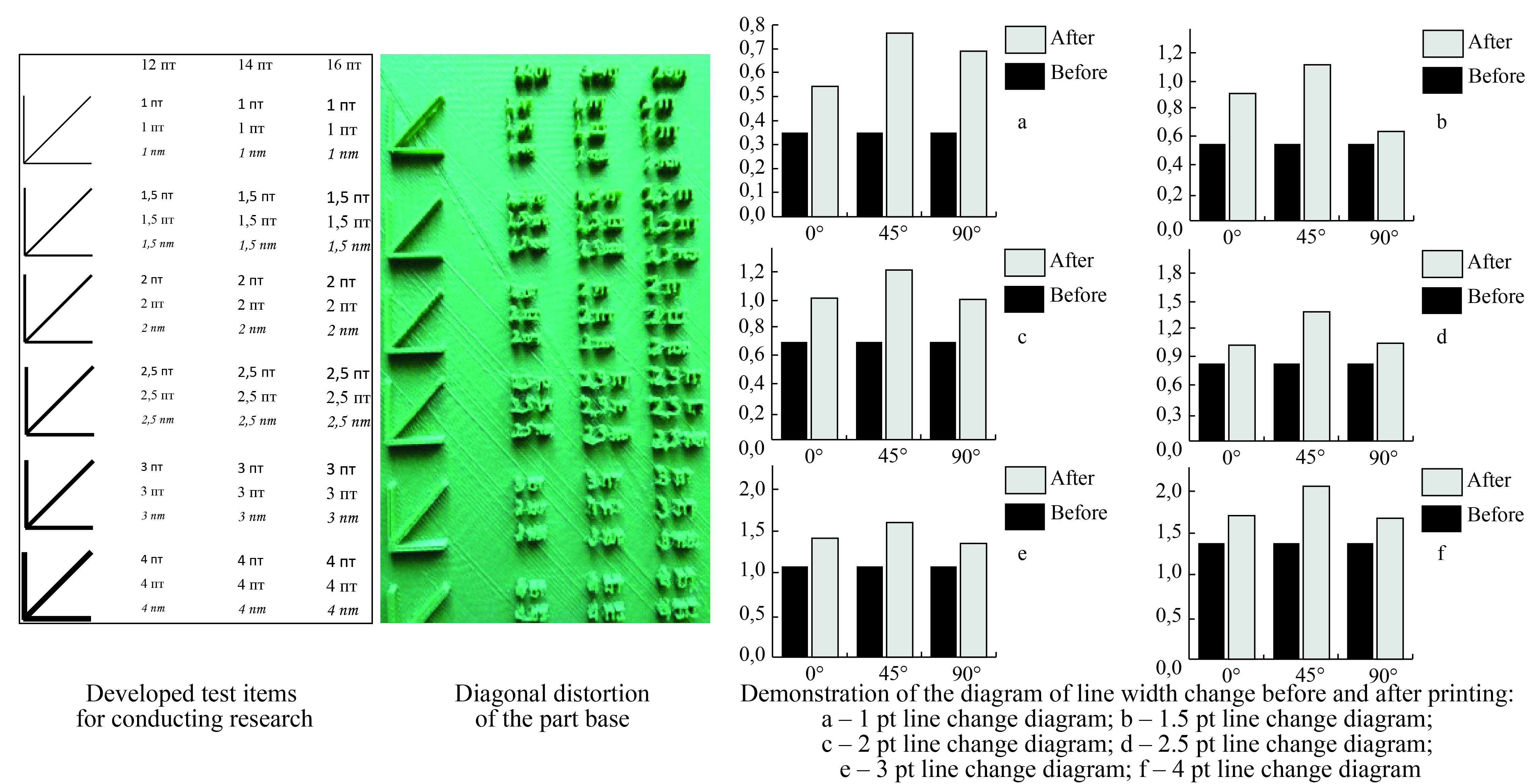

The main factors affecting the quality of finished products have been determined. The criterion to compare possible options for creating printed products was selected, namely, the examination method was considered. After processing the expert group summary, the consistency degree of opinions was determined using Kendall’s concordance coefficient. The most significant factor was identified, and further research is focused on it. Layer-by-layer deposition modeling was chosen as the technology for creating the test. Test fragments were developed, and materials and equipment to run the experiment were selected. A quantitative and qualitative assessment of the quality of 3D printing was carried out.

Following the conducted research, the shortcomings were taken into account, and a number of recommendations for further creation of the forthcoming high-quality product were made. Those recommendations refer to the optimal line width (1.5 points and more), typeface origin and font size (20 points and above) for the reproduction of text information, and thickness of the element base of printed products (minimum 2.5–3 mm).

The above recommendations allow a 3D printing product and its elements to achieve a remarkable quality level and visual appeal, as well as enable enterprises to use it as the basis of technological instructions for applying modern technologies.

References

- Yak ukrainska promyslovist dolaie voienni vyklyky. Available at: https://zn.ua/ukr/promyshliennost/jak-ukrajinska-promislovist-dolaje-vojenni-vikliki.html

- Ukrainskyi biznes pid chas viyny (2022). Nove shchomisiachne opytuvannia pidpryiemstv, 7, 43. Available at: https://business.diia.gov.ua/uploads/5/27491-rezul_tati_s_omogo_somisacnogo_opituvanna_kerivnikiv_promislovih_pidpriemstv_ukrains_kij_biznes_v_umovah_vijni.pdf

- Muraviov, O. V., Nyzhnyk, Yu. M., Petryk, V. F., Protasov, A. G., Syeryy, K. M. (2021). Current state and development prospects of additive technologies. Scientific Notes of Taurida National V.I. Vernadsky University. Series: Technical Sciences, 5, 114–119. doi: https://doi.org/10.32838/2663-5941/2021.5/18

- Sai Saran, O., Prudhvidhar Reddy, A., Chaturya, L., Pavan Kumar, M. (2022). 3D printing of composite materials: A short review. Materials Today: Proceedings, 64, 615–619. doi: https://doi.org/10.1016/j.matpr.2022.05.144

- Havenko, S. F., Hadzhynova, S. Ye., Labetska, M. T., Havenko, M. M. (2017). Research of influence of modern technologies of braille reproduction on tactile perception of information by blind and visually impaired people. Printing and publishing, 2, 107–116. Available at: http://nbuv.gov.ua/UJRN/Pivs_2016_2_14

- Labetska, M., Havenko, M. (2017). Application of 3D Technologies in Inclusive Environment. Technology and Technique of Typography (Tekhnolohiia I Tekhnika Drukarstva), 1 (55), 47–54. doi: https://doi.org/10.20535/2077-7264.1(55).2017.95073

- Anastasiadou, C., Vettese, S. (2019). “From souvenirs to 3D printed souvenirs”. Exploring the capabilities of additive manufacturing technologies in (re)-framing tourist souvenirs. Tourism Management, 71, 428–442. doi: https://doi.org/10.1016/j.tourman.2018.10.032

- Lee, D. K., Sin, K. S., Shin, C., Kim, J.-H., Hwang, K.-T., Kim, U.-S. Et al. (2023). Fabrication of 3D structure with heterogeneous compositions using inkjet printing process. Materials Today Communications, 35, 105753. doi: https://doi.org/10.1016/j.mtcomm.2023.105753

- Pekgor, M., Nikzad, M., Arablouei, R., Masood, S. (2021). Sensor-based filament fabrication with embedded RFID microchips for 3D printing. Materials Today: Proceedings, 46, 124–130. doi: https://doi.org/10.1016/j.matpr.2020.06.456

- Kushlyk-Dyvulska, O. I., Kushlyk, B. R. (2014). Osnovy teoriyi pryiniattia rishen. Kyiv: NTUU «KPI», 94. Available at: http://ela.kpi.ua/handle/123456789/6917

- Khatri, N. R., Egan, P. F. (2023). Energy Absorption of 3D Printed ABS and TPU Multimaterial Honeycomb Structures. 3D Printing and Additive Manufacturing. doi: https://doi.org/10.1089/3dp.2022.0196

- Chadha, U., Abrol, A., Vora, N. P., Tiwari, A., Shanker, S. K., Selvaraj, S. K. (2022). Performance evaluation of 3D printing technologies: a review, recent advances, current challenges, and future directions. Progress in Additive Manufacturing, 7 (5), 853–886. doi: https://doi.org/10.1007/s40964-021-00257-4

- Kumar, L. J., Pandey, P. M., Wimpenny, D. I. (Eds.) (2019). 3D Printing and Additive Manufacturing Technologies. Springer, 311. doi: https://doi.org/10.1007/978-981-13-0305-0

- Sandhu, K., Singh, S., Prakash, C., Subburaj, K., Ramakrishna, S. (Eds.) (2022). Sustainability for 3D Printing. Springer Tracts in Additive Manufacturing. Springer, 194. doi: https://doi.org/10.1007/978-3-030-75235-4

- Hui, J., Zhang, H., Lv, J., Lee, C.-H., Chen, C., Yan, Z. et al. (2023). Investigation and Prediction of Nano-Silver Line Quality upon Various Process Parameters in Inkjet Printing Process Based on an Experimental Method. 3D Printing and Additive Manufacturing. doi: https://doi.org/10.1089/3dp.2022.0292

- Perritano, J. (2018). 3D Printing. Saddleback Educational Publishing. Available at: https://worldcat.org/en/title/1020618227

- Popescu, D., Amza, C. G. (2022). 3D Printing onto Textiles: A Systematic Analysis of the Adhesion Studies. 3D Printing and Additive Manufacturing. doi: https://doi.org/10.1089/3dp.2022.0100

- Gibson, I., Rosen, D., Stucker, B. (2015) Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer, 498. doi: https://doi.org/10.1007/978-1-4939-2113-3

- Shishkovsky, I. V. (Ed.) (2016). New Trends in 3D Printing. IntechOpen, 270. doi: https://doi.org/10.5772/61398

- Horbachuk, V. M., Kushlyk-Dyvulska, O. I. (2023). Teoriya ymovirnostei ta matematychna statystyka. Kyiv: KPI im. Ihoria Sikorskoho, 351. Available at: https://ela.kpi.ua/handle/123456789/52357

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Tetiana Rozum, Kateryna Zolotukhina, Olga Kushlyk-Dyvulska, Anastasiya Petryshyna, Ivanna Marchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.