Determination of rational parameters of a device for leather feeding to the machining area

DOI:

https://doi.org/10.15587/1729-4061.2023.277393Keywords:

roller machine, conveying device, working rolls, leather squeezing, straightening rollersAbstract

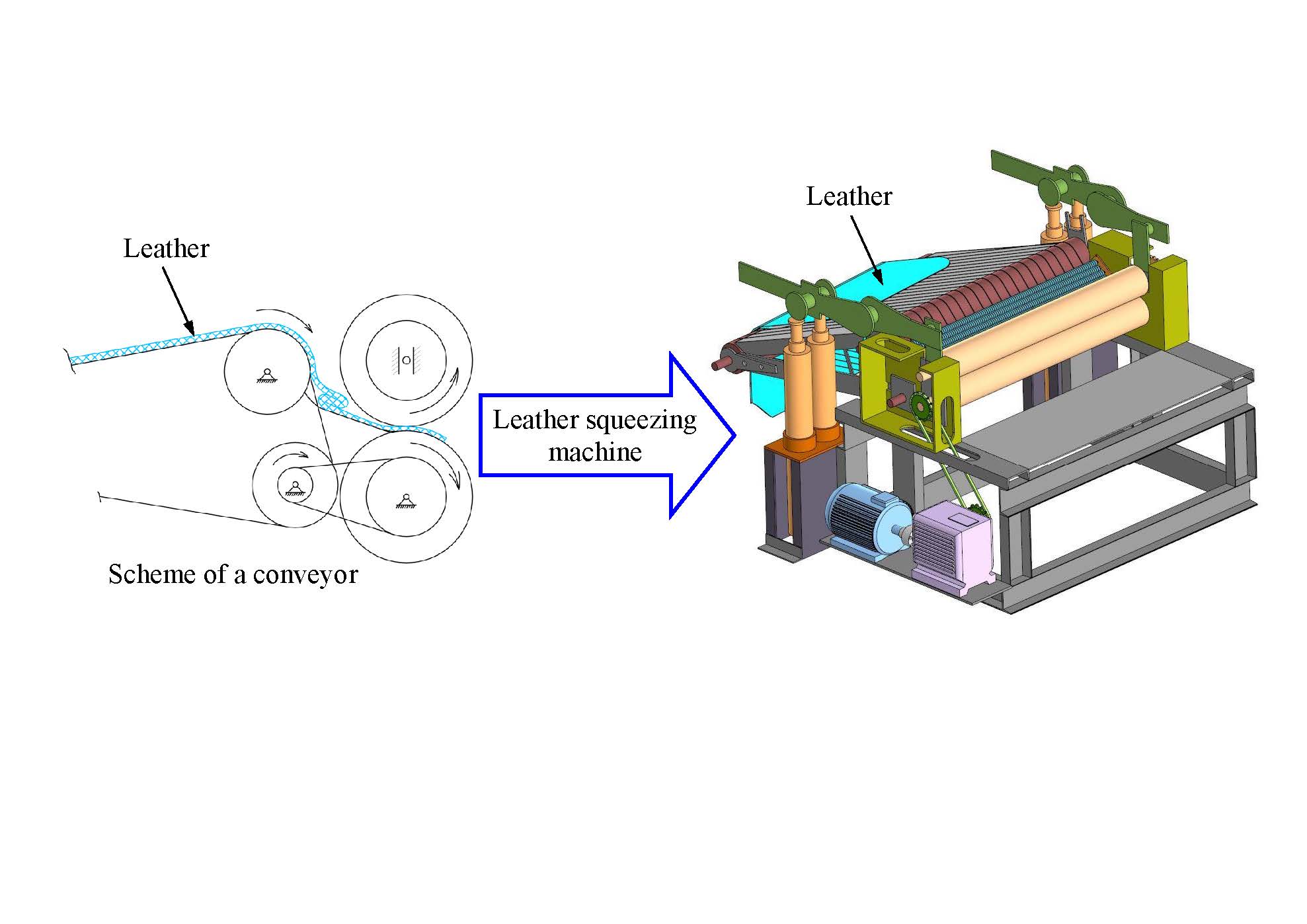

The quality of mechanical processing of the skin largely depends on the parameters of the skin feeding to the processing zone between the working rolls. The processed material at the entrance to the processing zone must be free of folds and wrinkles, i.e. one layer of material should enter the processing zone of the working rolls. Therefore, the input of the processed material into the zone of the working rolls is ensured with a rational selection of the profile of the guiding device for feeding the skin into the processing zone. A mathematical model was developed that allows the authors to determine the profile of the guiding device for leather feeding into the processing area between the working rollers, considering the modulus of elasticity and the density of the material being processed. The graphical solution to the mathematical model of the guiding device profile was made by a numerical method, and in order to prevent the leather saturated with liquid from sticking to the guiding surface, the friction coefficient was replaced with the rolling friction coefficient, and the rollers of the guiding device were placed at a certain angle to level out the folds of the leather and smoothly feed it to the processing area. A new design of roller technological machines was manufactured in laboratory settings. The roller machine is equipped with a new guiding device using rollers, with the possibility of free rotation around its axis. The rollers can be placed in several rows in a staggered arrangement. The developed design of the guiding device, due to the installation of the rollers at a certain angle relative to the direction of skin feed, makes it possible to smoothly transport the treated skin while eliminating longitudinal and transverse folds. The elimination of wrinkles contributed to an increase in the usable area of the treated leather samples. Experimental and testing work was conducted on a roller squeezing machine for processing leather samples using a new design of guiding device. The working width of the guiding device was 1500 mm, and the rollers of a diameter of 30 mm, allowed the straightening of the folds of the leather and moving it to the gripping zone of the working rollers. In the experimental study, the second-order D-optimal planning method was used with the Kano design matrix.

References

- Leather production in the world. Available at: http://www.splaix.ru/k5.html

- Burmistrov, A. G. (2006). Machines and apparatus for the production of leather and fur. Moscow: KolosS, 384. Available at: https://rusneb.ru/catalog/000199_000009_002909428/

- Leather Processing & Tanning Technology Handbook (2011). NIIR Board of Consultants & Engineers, 592. Available at: https://books.google.com.hk/books?id=hbKkCwAAQBAJ

- Gallardo, J. P., Pettersen, B., Andersson, H. I. (2013). Effects of free-slip boundary conditions on the flow around a curved circular cylinder. Computers & Fluids, 86, 389–394. https://doi.org/10.1016/j.compfluid.2013.07.023

- Schultz, R. A. (1992). Mechanics of curved slip surfaces in rock. Engineering Analysis with Boundary Elements, 10 (2), 147–154. doi: https://doi.org/10.1016/0955-7997(92)90045-9

- Nabiev, A., Tsoy, G., Bahadirov, G. (2023). Conditions for vertical pulling of semi-finished leather products under driving rollers. E3S Web of Conferences, 376, 01073. doi: https://doi.org/10.1051/e3sconf/202337601073

- Muhammad, R., Khan, M. I., Khan, N. B., Jameel, M. (2020). Magnetohydrodynamics (MHD) radiated nanomaterial viscous material flow by a curved surface with second order slip and entropy generation. Computer Methods and Programs in Biomedicine, 189, 105294. doi: https://doi.org/10.1016/j.cmpb.2019.105294

- Hayat, T., Qayyum, S., Alsaedi, A., Ahmad, B. (2020). Entropy generation minimization: Darcy-Forchheimer nanofluid flow due to curved stretching sheet with partial slip. International Communications in Heat and Mass Transfer, 111, 104445. doi: https://doi.org/10.1016/j.icheatmasstransfer.2019.104445

- Avramenko, A. A., Kuznetsov, A. V. (2009). Instability of a slip flow in a curved channel formed by two concentric cylindrical surfaces. European Journal of Mechanics - B/Fluids, 28 (6), 722–727. doi: https://doi.org/10.1016/j.euromechflu.2009.06.003

- Failli, F., Dini, G. (2004). An Innovative Approach to the Automated Stacking and Grasping of Leather Plies. CIRP Annals, 53 (1), 31–34. doi: https://doi.org/10.1016/s0007-8506(07)60638-6

- Bacardit, A., Baquero, G., Sorolla, S., Ollé, L. (2015). Evaluation of a new sustainable continuous system for processing bovine leather. Journal of Cleaner Production, 101, 197–204. doi: https://doi.org/10.1016/j.jclepro.2015.04.012

- Adzet, J. M. A. (2010). Pat No. WO2010070571A3. Procedure for the tanning of skins, material obtained during said procedure and device. Available at: https://patents.google.com/patent/WO2010070571A3/en

- Purnomo, E. (2015). Teknik Penyamakan Aldehida dan Sintetis. Yogyakarta.

- Morera, J. M., Bacardit, A., Olle, L., Costa, J., Germann, H. P. (2006). Study of a Chrome Tanning Process without Float and with Low-Salt Content as Compared to A Traditional Process Part II. Journal of the American Leather Chemists Association, 101 (12), 454–460. Available at: https://agris.fao.org/agris-search/search.do?recordID=US201300783975

- Loan, S., Liu, Y., Fan, H., Shi, B., Duan, Z. (2007). A novel pre-tanning agent for high exhaustion chromium tannage. Journal of the Society of Leather Technologists and Chemists, 91 (4), 149–153. Available at: https://www.scholarmate.com/A/MZFzIr

- Luo, Z., Zhang, X., Fan, H. et al. (2009). Modification of collagen for high Cr(III) absorption. Journal of the American Leather Chemists Association, 104, 149–155. Available at: https://journals.uc.edu/index.php/JALCA/article/view/2477/1838

- Sundar, V. J., Rangasamy, T., Sivakumar, V., Muralidharan, C. (2007). A Novel Pickle-Free High Exhaust Chrome Tanning Method - An Approach for Total Dissolved Solids Management. Journal of the Society of Leather Technologists and Chemists, 88 (5), 252–255.

- Thanikaivelan, P., Kanthimathi, M., Rao, J. R., Nair, B. U. (2002). A Novel Formaldehyde-Free Synthetic Chrome Tanning Agent for Pickle-Less Chrome Tanning: Comparative Study on Syntan versus Modified Basic Chromium Sulfate. Journal of the American Leather Chemists Association, 97 (4), 127–136. Available at: http://www.csircentral.net/index.php/record/view/50302

- Bahadirov, G. A., Abdukarimov, A., Bakhadirov, K. G. Musirov, M. U., Saidakhmetova, N. B. (2021). Pat. No. 01658 UZ. Device for processing sheet material.

- Bahadirov, G., Sultanov, T., Tsoy, G., Nabiev, A. (2021). Experimental dehydration of wet fibrous materials. E3S Web of Conferences, 264, 04060. doi: https://doi.org/10.1051/e3sconf/202126404060

- Bahadirov, G. A., Nosirov, M. I. (2022). Research and Analysis of Rational Parameters for a Conveying Mechanism of a Multi-operation Roller Machine. Proceedings of the 7th International Conference on Industrial Engineering (ICIE 2021), 154–165. doi: https://doi.org/10.1007/978-3-030-85233-7_18

- Amanov, A. T., Bahadirov, G. A., Nabiev, A. M. (2023). A Study on the Pressure Mechanism Improvement of a Roller-Type Machine Working Bodies. Materials, 16 (5), 1956. doi: https://doi.org/10.3390/ma16051956

- Amanov, A. T., Bahadirov, G. A., Tsoy, G. N., Nabiev, A. M. (2023). The Improvement of the Rheological Model of Leather. International Journal on Advanced Science, Engineering and Information Technology, 13 (1), 321. doi: https://doi.org/10.18517/ijaseit.13.1.17360

- Jeff Wu, C. F., Hamada, M. S. (2009). Experiments: planning, analysis, and optimization. John Wiley & Sons, Inc., 760.

- Tikhomirov, V. A. (1974). Planning and analysis of the experiment. Moscow: Light industry, 283.

- Constales, D., Yablonsky, G. S., D’hooge, D. R., Thybaut, J. W., Marin, G. B. (2017). Experimental Data Analysis. Advanced Data Analysis & Modelling in Chemical Engineering, 285–306. doi: https://doi.org/10.1016/b978-0-444-59485-3.00009-6

- Fávero, L. P., Belfiore, P. (2019). Design and Analysis of Experiments. Data Science for Business and Decision Making, 935–939. doi: https://doi.org/10.1016/b978-0-12-811216-8.00021-5

- Farooq, M. A., Nóvoa, H., Araújo, A., Tavares, S. M. O. (2016). An innovative approach for planning and execution of pre-experimental runs for Design of Experiments. European Research on Management and Business Economics, 22 (3), 155–161. doi: https://doi.org/10.1016/j.iedee.2014.12.003

- Sharma, A. K. (2005). Text Book of Circles and Parabola. Discovery Publishing House, 308.

- Butcher, J. C. (1987). The Numerical Analysis of Ordinary Differential Equations: Runge-Kutta and General Linear Methods. Wiley, 528.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Gayrat Bahadirov, Makhmarajab Musirov, Ayder Nabiev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.