Designing brazing filler metal for heat-resistant nickel alloys of new generation marine gas turbines

DOI:

https://doi.org/10.15587/1729-4061.2023.288340Keywords:

brazed joints, stressed state, high-temperature salt corrosion, long-term strengthAbstract

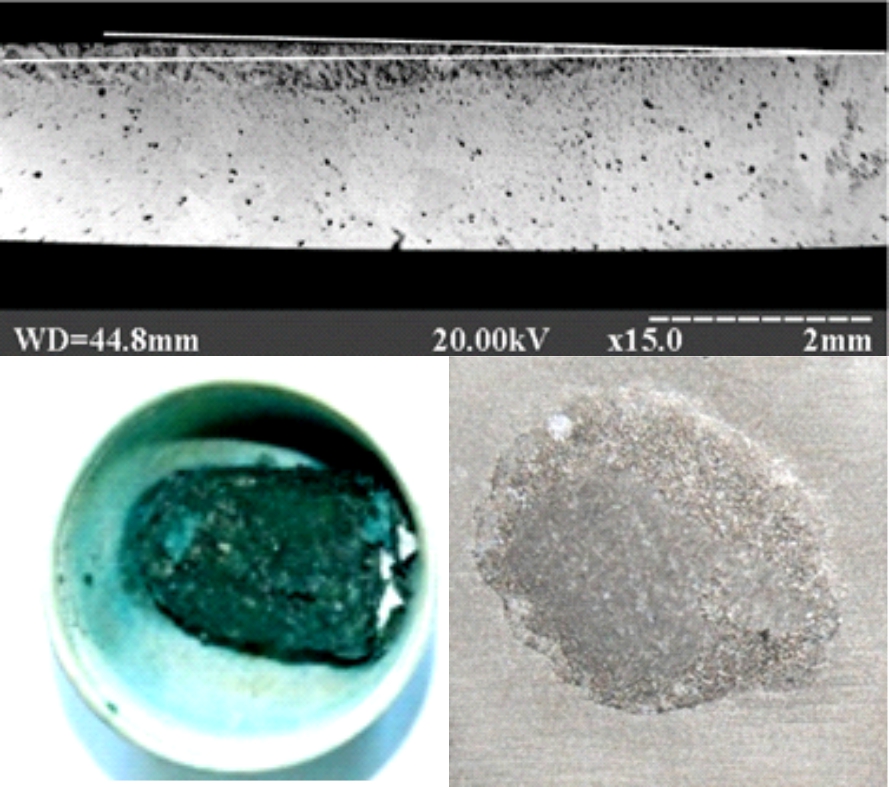

The object of research is the processes of the formation of brazed joints and the stressed state. The subject of research is structure, chemical composition, long-term high-temperature strength at a temperature of 900 °C, speed of high-temperature salt corrosion. Existing brazing filler metals have a high-temperature performance of 40–50 % of the performance of the SM93-VI and SM96-VI alloys. Despite this, brazing is the main technique of joining modern heat-resistant cast alloys. Therefore, the development of new brazing filler metals that ensure the formation of joints with increased long-term high-temperature strength is relevant. Ship gas turbine blades operate at a temperature of 900 °C. The purpose of the development of the new SBM-4 brazing filler metal is to achieve long-term high-temperature strength of brazed joints at a temperature of 900 °C at the level of 85–90 % of the strength of heat-resistant alloys SM93-VI and SM96-VI.

A two-stage method was used in the development of SBM-4 brazing filler metal. At the first stage, the chemical composition of the brazing filler metal base was determined, taking into account the peculiarities of operating conditions of the blades of marine gas turbine engines and the achievements of materials science of heat-resistant alloys. At the second stage, the depressant and its necessary content were selected. Computer software was used to determine the distribution between the γ- and γ'-phases, taking into account the participation of each element in both dispersion and solid-solution strengthening. Rational limits of concentrations of alloying elements were determined. The criterion was the minimum susceptibility of brazing filler metal to the formation of brittle phases, taking into account the influence of chromium, rhenium, and tantalum concentrations on resistance to high-temperature salt corrosion and high-temperature performance. The long-term strength of SM93-VI and CM96-VI alloys brazed with SBM-4 brazing filler metal is 89–91 % of the strength of the base metal. Technologies of brazing and correction of casting defects have been introduced into production.

References

- Yushchenko, K. A., Savchenko, V. S., Chervyakov, N. O., Zvyagintseva, A. V., Velikoivanenko, E. A. (2016). Multi-scale Modeling of the Stress-Strain State During Welding of Ni-Based Alloys. Cracking Phenomena in Welds IV, 289–303. doi: https://doi.org/10.1007/978-3-319-28434-7_14

- Jung, D. H., Sharma, A., Mayer, M., Jung, J. P. (2018). A Review on Recent Advances in Transient Liquid Phase (TLP) Bonding for Thermoelectric Power Module. Reviews on Advanced Materials Science, 53 (2), 147–160. doi: https://doi.org/10.1515/rams-2018-0011

- Kvasnytskyi, V., Korzhyk, V., Kvasnytskyi, V., Mialnitsa, H., Dong, C., Pryadko, T. et al. (2020). Designing brazing filler metal for heat-resistant alloys based on NI3AL intermetallide. Eastern-European Journal of Enterprise Technologies, 6 (12 (108)), 6–19. doi: https://doi.org/10.15587/1729-4061.2020.217819

- Makhnenko, V. I., Kvasnitsky, V. V., Ermolaev, G. V. (2008). Stress-Strain State Of Diffusion Bonds Between Metals With Different Physical-Mechanical Properties. The Paton Welding Journal, 8, 2–6. Available at: https://patonpublishinghouse.com/tpwj/pdf/2008/tpwj200808all.pdf

- Makhnenko, V. I., Kvasnitsky, V. V. (2009). Stress-strain state of assemblies of the cylindrical shape in diffusion bonding. The Paton Welding Journal, 2, 2–7. Available at: https://patonpublishinghouse.com/eng/journals/tpwj/2009/02/01

- Kopel'man, L. A. (2010). Osnovy teorii prochnosti svarnykh konstruktsiy. Sankt-Peterburg: izd. «Lan'», 464.

- Parfenov, A. N. (2008). Vvedenie v teoriyu prochnosti payanykh soedineniy. Tekhnologii v elektronnoy promyshlennosti, 2, 46–52. Available at: https://pselectro.ru/file-storage/1604046402-2008-02-46.pdf

- Ermolaev, G. V., Martynenko, V. A., Olekseenko, S. V., Labartkava, A. V., Matvienko, M. V. (2017). Effect of the Rigid Interlayer Thickness on the Stress-Strain State of Metal-Graphite Assemblies Under Thermal Loading. Strength of Materials, 49 (3), 422–428. doi: https://doi.org/10.1007/s11223-017-9882-4

- Cai, X., Gao, Y., Wang, X., Zhang, W., Liu, W., Shen, X. et al. (2020). Triaxial Constraint and Tensile Strength Enhancement in Brazed Joints. Metallurgical and Materials Transactions A, 51 (11), 5587–5596. doi: https://doi.org/10.1007/s11661-020-05984-x

- Riggs, B. E. (2017). Multi-scale computational modeling of Ni-base superalloy brazed joints for gas turbine applications. Ohio State University, 262. Available at: https://etd.ohiolink.edu/acprod/odb_etd/etd/r/1501/10?clear=10&p10_accession_num=osu1492631613686228

- Kvasnytskyi, V. V., Matviienko, M. V., Buturlia, Y. A. (2020). Influence of properties of the interlayer solder on the stress-strain state of brazed nodes from heat-resistant alloys. Collection of Scientific Publications NUS, 4, 119–128. doi: https://doi.org/10.15589/znp2020.4(482).14

- Malashenko, I. S., Mazurak, V. E., Kushnareva, T. N., Kurenkova, V. V., Zavidonov, V. G., Yavdoschina, E. F. (2014). Payka v vakuume litogo nikelevogo splava ZhS6U kompozitsionnymi pripoyami na osnove VPr-36. Chast' 1. Sovremennaya elektrometallurgiya, 4, 49–58. Available at: https://patonpublishinghouse.com/sem/pdf/2014/pdfarticles/04/9.pdf

- Fridman, Ya. B. (1974). Mekhanicheskie svoystva metallov. Ch. 1. Deformatsiya i razrushenie. Moscow: Mashinostroenie, 472.

- Yue, X., Liu, F., Chen, H., Wan, D., Qin, H. (2018). Effect of Bonding Temperature on Microstructure Evolution during TLP Bonding of a Ni3Al based Superalloy IC10. MATEC Web of Conferences, 206, 03004. doi: https://doi.org/10.1051/matecconf/201820603004

- Verkhuliuk, A. N., Maksiuta, I. I., Kvasnytska, Yu. H., Mialnytsia, H. P., Mykhnian, O. V. (2016). Fazovo-strukturna stabilnist zharomitsnoho koroziynostiykoho splavu dlia lytykh robochykh lopatok HTU. Metaloznavstvo ta obrobka metaliv, 3, 3–9.

- Kvasnytska, Yu. H., Ivaskevych, L. М., Balytskyi, О. І., Maksyuta, І. І., Myalnitsa, H. P. (2020). High-Temperature Salt Corrosion of a Heat-Resistant Nickel Alloy. Materials Science, 56 (3), 432–440. doi: https://doi.org/10.1007/s11003-020-00447-5

- Yermolaiev, H. V., Kvasnytskyi, V. V., Kvasnytskyi, V. F. (2015). Paiannia materialiv. Mykolaiv: NUK, 340. Available at: https://www.researchgate.net/profile/Gennadii-Yermolaiev/publication/321796483_PAANNA_MATERIALIV/links/5a3237c3458515afb65dbe2c/PAANNA-MATERIALIV.pdf

- Maksymova, S. V., Voronov, V. V., Kovalchuk, P. V., Zvolinsky, I. V. (2023). Influence of Alloying Elements on Heat Resistance of Ni-Based Fillers and Brazed Joints. Materials Science, 58 (5), 643–648. doi: https://doi.org/10.1007/s11003-023-00711-4

- Balyts’kyi, A. I., Kvasnyts’ka, Yu. H., Ivas’kevich, L. M., Myal’nitsa, H. P. (2018). Corrosion- and Hydrogen-Resistance of Heat-Resistant Blade Nickel-Cobalt Alloys. Materials Science, 54 (2), 230–239. doi: https://doi.org/10.1007/s11003-018-0178-z

- Іvas’kevych, L. М. (2020). Influence of Alloying with Cobalt and Hafnium on the Corrosion and Hydrogen Resistances of Refractory Nickel Alloy. Materials Science, 55 (5), 730–736. doi: https://doi.org/10.1007/s11003-020-00365-6

- Glotka, O. A., Olshanetskii, V. Yu. (2023). Mathematical Prediction of the Properties of Heat-Resistant Nickel Alloys After Directional Crystallization. Materials Science, 58 (5), 679–685. doi: https://doi.org/10.1007/s11003-023-00716-z

- Maksymova, S. V., Voronov, V. V., Kovalchuk, P. V. (2021). Mathematical modeling of melting temperature range and phase composition of multicomponent nickel alloys. The Paton Welding Journal, 2021 (10), 28–32. doi: https://doi.org/10.37434/tpwj2021.10.04

- Musina, O. N. (2015). Planirovanie i postanovka nauchnogo eksperimenta. Moscow; Berlin: Direkt-Media, 89. doi: https://doi.org/10.23681/274057

- Kvasnytskyi, V. V., Mialnitsa, H. P., Kvasnytskyi, V. F., Malyi, O. B., Samokhin, S. M., Buturlia, Ye. A., Matviienko, M. V. (2020). Pat. No. 127057 UA. Prypiy dlia paiannia zharomitsnykh nikelevykh splaviv morskykh hazovykh turbin. declareted: 21.07.2020; published: 29.03.2023, Bul. No. 13/2023. Available at: https://sis.nipo.gov.ua/uk/search/detail/1728602/

- Depiver, J., Mallik, S., Harmanto, D. (2020). Solder joint failures under thermo-mechanical loading conditions – A review. Advances in Materials and Processing Technologies, 7 (1), 1–26. doi: https://doi.org/10.1080/2374068x.2020.1751514

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Viktor Kvasnytskyi, Volodymyr Korzhyk, Viacheslav Kvasnytskyi, Maksym Matviienko, Yevhen Buturlia, Ivan Lahodzinskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.