Determining the rational structure of multilayer technical fabric for woven power clamps

DOI:

https://doi.org/10.15587/1729-4061.2024.296839Keywords:

woven power clamps, multi-layer technical fabric, beating force, thread tensionAbstract

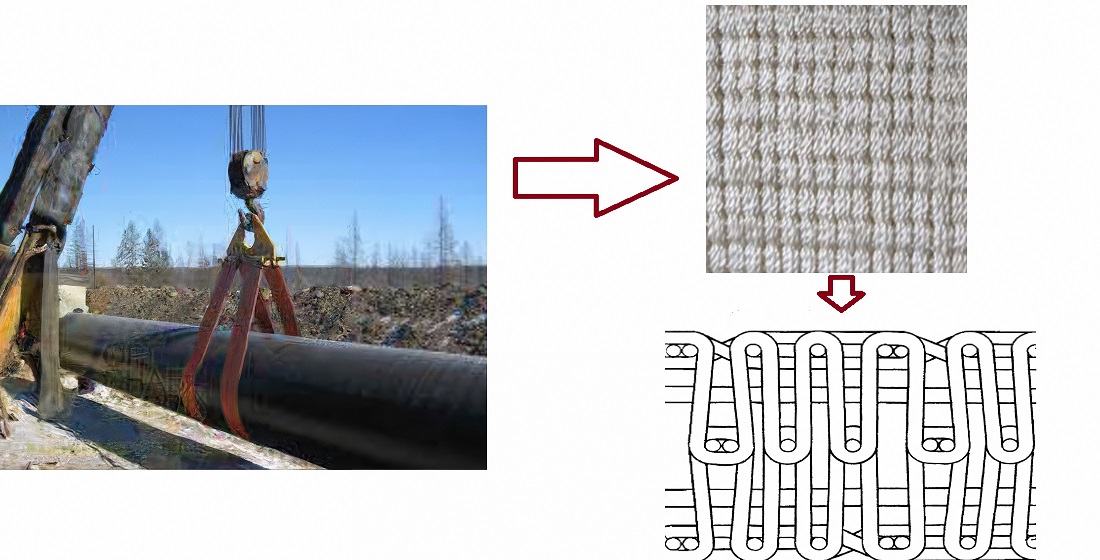

The object of research is multi-layered technical fabrics for woven power clamps. A task to determine the rational structure of a multi-layer technical fabric for power clamps has been solved, which makes it possible to achieve an effect when introduced into production through the minimization of raw material costs and the reduction of energy costs for manufacturing a unit of products. The value of the beating force, the tension of warp threads of the outer protective layers, the force layers, the warp threads for connecting the outer protective layers, and the force layers for two structures of multilayer technical fabric were studied. A comparative analysis of conditions for the formation of two multilayer fabrics from polyamide threads was carried out and a multilayer fabric with the most rational structure was selected, the formation of which would require less technological effort. Experimental studies have made it possible to build regression dependences on determining the influence of the initial tension of warp threads of the outer protective layers on the beating force value. The joint effect of the size of an overstep and the different tension of a shed on the beating force value was established, depending on the structure of a multilayer technical fabric. It is shown that when the tension of warp threads of the outer protective layers increases, the beating force value increases. A value of the tension of warp threads in outer protective layers, force layers, warp threads for connecting the outer protective layers and force layers in the position of an overstep and at the moment of thread beating was determined. Analysis of regression dependences will make it possible to determine the optimal loading parameters of the loom. It has been proven that the beating force value is affected by the structure of a multi-layer technical fabric and the tension of warp threads in outer protective layers. The improved multi-layer technical fabric is used for laying pipes with an external factory-made polyethylene coating

References

- Sirková, B. K., Mertová, I. (2017). Woven fabric structural pore models analysis. Fibres and Textiles, 1, 15–24. Available at: http://vat.ft.tul.cz/Archive/VaT_2017_1.pdf

- Shcherban’, V., Melnyk, G., Sholudko, M., Kolysko, O., Kalashnyk, V. (2019). Improvement of structure and technology of manufacture of multilayer technical fabric. Fibres and Textiles, 2, 54–63. Available at: http://vat.ft.tul.cz/2019/2/VaT_2019_2_10.pdf

- Barburski, M. (2019). Formation of the textile structures for a specified purpose. Fibres and Textiles, 1, 3–10. Available at: http://vat.ft.tul.cz/2019/1/VaT_2019_1_1.pdf

- Barburski, M. (2014). Analysis of the mechanical properties of conveyor belts on the three main stages of production. Journal of Industrial Textiles, 45 (6), 1322–1334. https://doi.org/10.1177/1528083714559567

- Krmela, J., Krmelova, V. (2018). The tests of low cyclic loading of composites with textile structure on test machine with video-extensometer. Fibres and Textiles, 2, 52–58. Available at: http://vat.ft.tul.cz/2018/2/VaT_2018_2_9.pdf

- Shcherban', V. Yu. (1990). Opredelenie tehnologicheskih usiliy v protsesse priboya pri formirovanii mnogosloynoy tehnicheskoy tkani. Izvestiya vysshih uchebnyh zavedeniy. Tehnologiya tekstil'noy promyshlennosti, 3 (195), 44–47. Available at: https://er.knutd.edu.ua/handle/123456789/17888

- Koo, Y.-S., Kim, H.-D. (2002). Friction of Cotton Yarn in Relation to Fluff Formation on Circular Knitting Machines. Textile Research Journal, 72 (1), 17–20. https://doi.org/10.1177/004051750207200103

- Weber, M. O., Ehrmann, A. (2012). Necessary modification of the Euler–Eytelwein formula for knitting machines. Journal of the Textile Institute, 103 (6), 687–690. https://doi.org/10.1080/00405000.2011.598665

- Shcherban’, V., Makarenko, J., Petko, A., Melnyk, G., Shcherban’, Y., Shchutska, H. (2020). Computer implementation of a recursion algorithm for determining the tension of a thread on technological equipment based on the derived mathematical dependences. Eastern-European Journal of Enterprise Technologies, 2 (1 (104)), 41–50. https://doi.org/10.15587/1729-4061.2020.198286

- Kovar, R. (2007). Impact of directions on frictional properties of a knitted fabric. Fibres and Textiles, 2, 15–20. Available at: http://vat.ft.tul.cz/Archive/VaT_2007_2.pdf

- Sodomka, L., Vargovd, H. (2002). Connection between structure, symmetry and anisotropy of mechanical properties of woven fabric. Fibres and Textiles, 4, 142–148. Available at: http://vat.ft.tul.cz/Archive/VaT_2002_4.pdf

- Shcherban’, V., Kolysko, O., Melnyk, G., Sholudko, M., Shcherban’, Y., Shchutska, G. (2020). Determining tension of yarns when interacting with guides and operative parts of textile machinery having the torus form. Fibres and Textiles, 4, 87–95. Available at: http://vat.ft.tul.cz/2020/4/VaT_2020_4_12.pdf

- Shcherban’, V., Makarenko, J., Melnyk, G., Shcherban’, Y., Petko, A., Kirichenko, A. (2019). Effect of the yarn structure on the tension degree when interacting with high-curved guide. Fibres and Textiles, 4, 59–68. Available at: http://vat.ft.tul.cz/2019/4/VaT_2019_4_8.pdf

- Moučková, E., Mertová, I., Hajská, Š., Vyšanská, M. (2018). Behavior of two and three-fold twisted multifilament yarns. Fibres and Textiles, 4, 51–60. Available at: http://vat.ft.tul.cz/2018/4/VaT_2018_4_11.pdf

- Stepanovic, J., Stamenkovic, J., Stojanovic, N. (2003). The influence of size on warp characterist. Fibres and Textiles, 4, 168–171. Available at: http://vat.ft.tul.cz/Archive/VaT_2003_4.pdf

- Döonmez, S., Marmarali, A. (2004). A Model for Predicting a Yarn’s Knittability. Textile Research Journal, 74 (12), 1049–1054. https://doi.org/10.1177/004051750407401204

- Yakubitskaya, I. A., Chugin, V. V., Shcherban', V. Yu. (1997). Dinamicheskiy analiz usloviy raskladki na tortsevyh uchastkah kanavki motal'nogo barabanchika. Izvestiya vysshih uchebnyh zavedeniy. Tehnologiya tekstil'noy promyshlennosti, 5, 33–36. Available at: https://er.knutd.edu.ua/handle/123456789/17840

- Liu, X., Chen, N., Feng, X. (2008). Effect of Yarn Parameters on the Knittability of Glass Ply Yarn. Fibres & Textiles in Eastem Europe, 16, 90–93. Available at: https://www.researchgate.net/publication/242356724_Effect_of_Yarn_Parameters_on_the_Knittability_of_Glass_Ply_Yarn

- Hammersley, M. J. (1973). 7—A simple yarn-friction tester for use with knitting yarns. The Journal of The Textile Institute, 64 (2), 108–111. https://doi.org/10.1080/00405007308630420

- Sodomka, L., Chrpová, E. (2008). Method of determination of euler friction coefficients of textiles. Fibres and Textiles, 2-3, 28–33. Available at: http://vat.ft.tul.cz/Archive/VaT_2008_2_3.pdf

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Volodymyr Shcherban, Gennadij Melnyk, Marijna Kolysko, Anton Kirichenko, Yury Shcherban, Serhii Lukianenko, Ihor Ostashevskyi, Pavlo Vdovin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.