Substantiating the rational parameters and operation modes for the hemp seed centrifugal dehuller

DOI:

https://doi.org/10.15587/1729-4061.2024.300174Keywords:

hemp, seed, seed kernel, separation, cleaning, rotation frequency, centrifugal dehullerAbstract

The object of research is technological processes, seeds of industrial hemp, and working bodies of the dehuller.

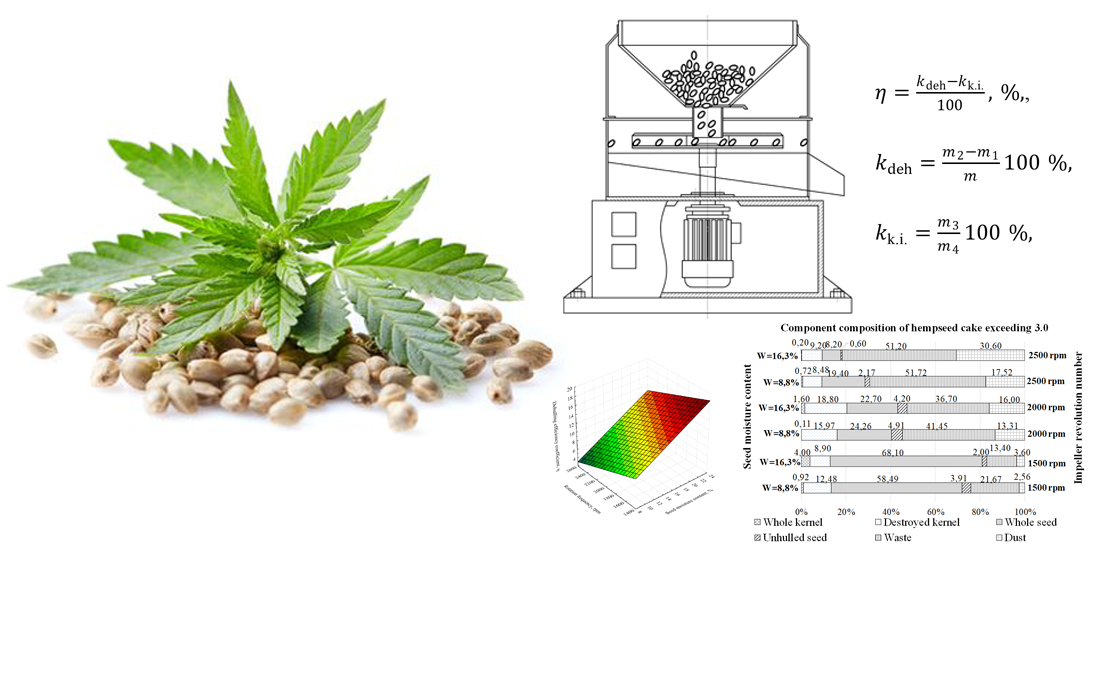

A centrifugal-type device for crushing hemp seeds with a closed sector-type working body has been designed. Owing to this, the task related to seed dehulling was solved with a high level of efficiency in separating the seed coat from the kernel.

The rational parameters for the dehuller have been substantiated: the diameter of the impeller is 162 mm, the gap between the impeller and the seed repelling panel is 80 mm, the frequency of rotation of the impeller is 2000 min–1. It was established that with the specified parameters and moisture content of the seeds within the limits of conditional (12.0–13.0 %), it is advisable to carry out dehulling process without preliminary separation of the seeds into fractions by width.

It was established that an increase in seed size leads to a corresponding increase in the weight share of seed kernels. About 58.2 % of the main mass of seeds is the average fraction with a width of 2.5 to 3.0 mm.

It was found that reducing the diameter of the impeller (from 236 mm to 162 mm) at a seed moisture content of 8.8 % improved the efficiency of dehulling. At a rotation frequency of the impeller of 2000 min–1, the highest total number of intact and destroyed kernels (23.23–29.33 %) was achieved for the two studied moistures. With an increase in seed moisture content from 8.8 % to 12.0 %, the number of dehulled kernels in the hempseed cake increased.

It was noted that for seeds with a moisture content of 8.8 %, an increase in the gap led to a decrease in the dehulling efficiency for each of the three investigated seed fractions. The total number of dehulled kernels under such conditions decreased by 2.4–6.8 % and amounted to 16.4–26.9 %. For seeds with a moisture content of 12.0 %, an increase in the gap, on the contrary, increased the dehulling efficiency for each of the three investigated seed fractions. The total number of dehulled kernels for seeds of marked moisture increased within the range of 1.4–3.6 % and amounted to 27.4–31.0 %

References

- Tkachenko, S., Mokher, Yu., Laiko, I., Zhuplatova, L., Vyrovets, V., Mishchenko, S. ta in. (2021). Dovidnyk konopliara. Sumy: Ellada, 27.

- Sheichenko, V., Shevchuk, V., Dudnikov, I., Koropchenko, S., Dnes, V., Skoriak, Y., Skibchyk, V. (2022). Devising technologies for harvesting hemp with belt threshers. Eastern-European Journal of Enterprise Technologies, 1 (1 (115)), 67–75. https://doi.org/10.15587/1729-4061.2022.251126

- Derzhavnyi reiestr sortiv roslyn, prydatnykh dlia poshyrennia v Ukraini. Available at: https://minagro.gov.ua/file-storage/reyestr-sortiv-roslin

- Vyrovets, V., Laiko, I., Myhal, M., Dudukova, S., Zhuplatova, L. et al. (2018). Konopliarstvo: naukovi zdobutky i perspektyvy. Sumy: FOP Shcherbyna, 158.

- Schultz, C. J., Lim, W. L., Khor, S. F., Neumann, K. A., Schulz, J. M., Ansari, O. et al. (2020). Consumer and health-related traits of seed from selected commercial and breeding lines of industrial hemp, Cannabis sativa L. Journal of Agriculture and Food Research, 2, 100025. https://doi.org/10.1016/j.jafr.2020.100025

- Montero, L., Ballesteros-Vivas, D., Gonzalez-Barrios, A. F., Sánchez-Camargo, A. del P. (2023). Hemp seeds: Nutritional value, associated bioactivities and the potential food applications in the Colombian context. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.1039180

- Alonso-Esteban, J. I., Pinela, J., Ćirić, A., Calhelha, R. C., Soković, M., Ferreira, I. C. F. R. et al. (2022). Chemical composition and biological activities of whole and dehulled hemp (Cannabis sativa L.) seeds. Food Chemistry, 374, 131754. https://doi.org/10.1016/j.foodchem.2021.131754

- Presa-Lombardi, J., García, F., Gutierrez-Barrutia, M. B., Cozzano, S. (2023). Hemp seed’s (Cannabis Sativa L) nutritional potential for the development of snack functional foods. OCL, 30, 24. https://doi.org/10.1051/ocl/2023025

- Romanić, R. S., Lužaić, T. Z. (2022). Dehulling effectiveness of high-oleic and linoleic sunflower oilseeds using air-jet impact dehuller: a comparative study. Food Science and Technology, 42. https://doi.org/10.1590/fst.58620

- Машина насіннєвійна НВХ. Available at: https://simo.com.ua/en/oborudovanie/mashina-semenoveechnaya-nvx

- Perevalov, L., Fadeev, L., Piven, O., Timchenko, V., Diachenko, M. (2020). Theoretical and experimental researches of the process of seed dehullingof sunflower confectionery sort. Integrated Technologies and Energy Saving, 2, 57–68. https://doi.org/10.20998/2078-5364.2020.2.07

- Lindström, L. I., Franchini, M. C., Nolasco, S. M. (2021). Sunflower fruit hullability and structure as affected by genotype, environment and canopy shading. Annals of Applied Biology, 180 (3), 338–347. https://doi.org/10.1111/aab.12735

- Gupta, R. K., Das, S. K. (2000). Fracture resistance of sunflower seed and kernel to compressive loading. Journal of Food Engineering, 46 (1), 1–8. https://doi.org/10.1016/s0260-8774(00)00061-3

- Ullegaddi, M. M., Mahandra Babu, N. C., Faisal, A. R., Mohammad, M., Shreenidhi, M. S., Anjum, S. (2021). Design and development of compact Foxtail millet deshelling machine. Materials Today: Proceedings, 42, 781–785. https://doi.org/10.1016/j.matpr.2020.11.314

- Hasantabar, S., Seyedi, S., Kalantari, D. (2019). Design, construction and evaluation of a seed pod husker and testing with soybean and mung bean. Agricultural Engineering International: The CIGR Journal, 21, 90–99. Available at: https://cigrjournal.org/index.php/Ejounral/article/view/4866/

- Kang, D., Wang, Y., Fan, Y., Chen, Z. (2018). Research and development of Camellia oleifera fruit sheller and sorting machine. IOP Conference Series: Earth and Environmental Science, 108, 042051. https://doi.org/10.1088/1755-1315/108/4/042051

- Dehulling Ancient Grains: Economic Considerations and Equipment. https://eorganic.org/node/13028

- Khodabakhshian, R., Bayati, M. R., Shakeri, M. (2011). Performance Evaluation of a Centrifugal Peeling System for Pistachio Nuts. International Journal of Food Engineering, 7 (4). https://doi.org/10.2202/1556-3758.2135

- Complex Oilseed Processing. Available at: https://www.farmet.cz/en/complex-oilseed-processing

- Khaliullin, D., Badretdinov, I., Naficov, I., Lukmanov, R. (2021). Theoretical justification of design and technological parameters of hulling machine main working bodies. Engineering for Rural Development. https://doi.org/10.22616/erdev.2021.20.tf321

- Zhang, J. (2019). Design of the gordon euryale seed automatic shelling machine. Journal of Physics: Conference Series, 1423 (1), 012053. https://doi.org/10.1088/1742-6596/1423/1/012053

- Sun, Q., Wang, C., Wang, Z., Zhao, Y., Bao, C. (2017). Design and Experiment of a Peanut Shelling Machine. Agricultural Research, 6 (3), 304–311. https://doi.org/10.1007/s40003-017-0265-7

- Nasinnia silskohospodarskykh kultur. Metody vyznachennia yakosti. DSTU 4138-2002. Kyiv: Derzhspozhyvstandart Ukrainy. Available at: https://www.agrodialog.com.ua/wp-content/uploads/2018/04/dstu-4138_2002.pdf

- Netreba, A., Teslenko, S., Vriukalo, E., Perevalov, L., Sadovnychyi, H. (2014). Influence of conditions dehulling sunflower seeds on transition wax in sunflower oil. Eastern-European Journal of Enterprise Technologies, 1 (10 (67)), 41. https://doi.org/10.15587/1729-4061.2014.20793

- Koropchenko, S. P., Petrachenko, D. O. (2018). Pat. No. 122649 UA. Prystriy dlia obrushuvannia nasinnia konopel. MPK B02B 3/02, C11B 1/04 No. u201705606; declareted: 06.06.2017; published: 25.01.2018, Bul. No. 2.

- Khailis, H. A., Konovaliuk, D. M. (1992) Osnovy proektuvannia i doslidzhennia silskohospodarskykh mashyn. Kyiv: NMK VO, 320.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Viktor Sheichenko, Dmytro Petrachenko, Serhii Koropchenko, Ivan Rogovskii, Oleksandr Gorbenko, Mykhailo Volianskyi, Denys Sheichenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.