Розробка моделі робочого процесу камери згоряння газотурбінного двигуна працюючого на метанолі

DOI:

https://doi.org/10.15587/1729-4061.2024.301325Ключові слова:

відносна витрата палива, камера згоряння, метанол, ентальпія, математична модель камери згорянняАнотація

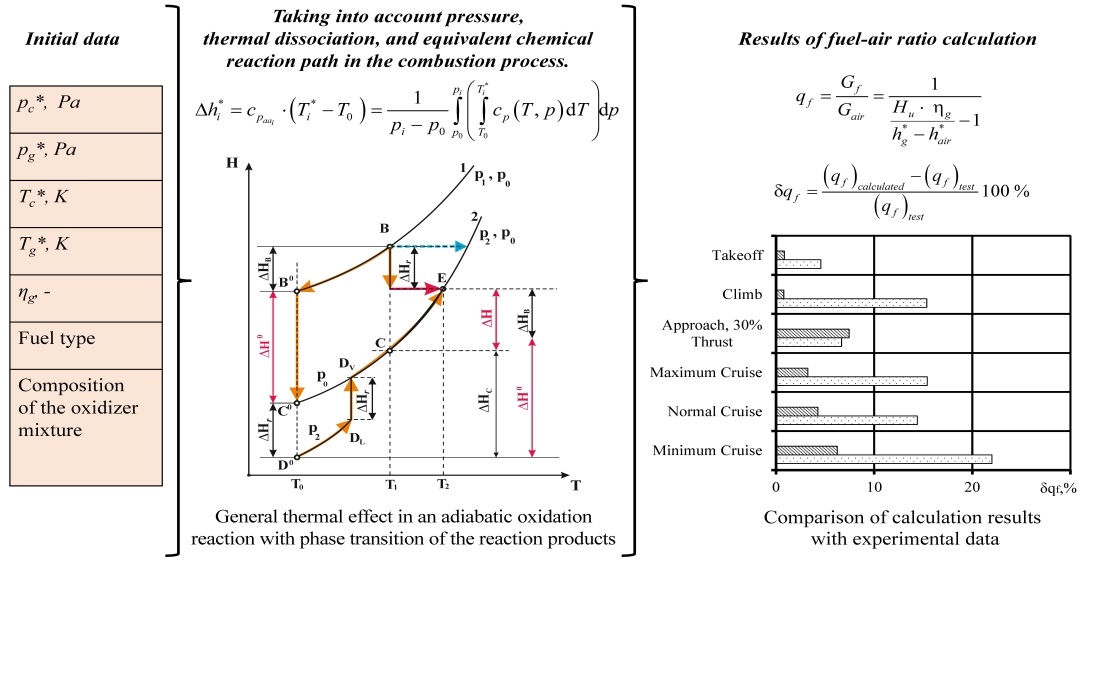

Використання метанолу в якості палива для авіаційних та стаціонарних газотурбінних двигунів (ГТД) є пріоритетним напрямком у двигунобудуванні. Загальновідомо, що при моделюванні характеристик ГТД математичними моделями (ММ) першого рівня існує похибка розрахунку питомої витрати палива, що викликано спрощеним описом робочого процесу камери згоряння (КЗ). Об’єктом дослідження є робочий процес у КЗ ГТД, що працює на метанолі. Особливістю розробленої ММ робочого процесу КЗ ГТД є використання залежностей ентальпії від температури, тиску та складу суміші. Залежності ентальпії в такій формі враховують ефект термічної дисоціації в неявному вигляді і дозволяють коректно скласти еквівалентний шлях реакції горіння. Для двох компонентів (H2O та CO2) врахування тиску призводить до того, що при стандартній температурі та парціальних тисках вище тиску насичення ці компоненти знаходяться в рідкому стані. Це при незмінній величині збільшення ентальпії в еквівалентному процесі нагрівання продуктів згоряння від стандартної температури до температури в кінці адіабатного підведення теплоти змінює цю температуру в меншу сторону. Уточнення температури на виході з камери згоряння призводить до зміни всіх розрахункових характеристик КЗ, включаючи відносну витрату палива КЗ. Результати розрахунку відносної витрати палива зіставлені з відомими експериментальними даними по камері згоряння двигуна CF6-80A фірми «General Electric» (США). Середня похибка розрахунку відносної витрати палива не перевищує 4 %. Розроблена модель може бути імплементована в існуючі та розроблювані ММ ГТД для температур кінця процесу згоряння нижче 2600 K

Посилання

- Gupta, K. K., Rehman, A., Sarviya, R. M. (2010). Bio-fuels for the gas turbine: A review. Renewable and Sustainable Energy Reviews, 14 (9), 2946–2955. https://doi.org/10.1016/j.rser.2010.07.025

- Wang, C., Cheng, K., Qin, J., Shao, J., Huang, H. (2022). Performance comparison of three chemical precooled turbine engine cycles using methanol and n-decane as the precooling fuels. Energy, 249, 123606. https://doi.org/10.1016/j.energy.2022.123606

- Burnes, D., Camou, A. (2019). Impact of Fuel Composition on Gas Turbine Engine Performance. Journal of Engineering for Gas Turbines and Power, 141 (10). https://doi.org/10.1115/1.4044238

- Cherednichenko, O., Havrysh, V., Shebanin, V., Kalinichenko, A., Mentel, G., Nakonieczny, J. (2020). Local Green Power Supply Plants Based on Alcohol Regenerative Gas Turbines: Economic and Environmental Aspects. Energies, 13 (9), 2156. https://doi.org/10.3390/en13092156

- Ayaz, S. K., Altuntas, O., Caliskan, H. (2021). Enhanced life cycle modelling of a micro gas turbine fuelled with various fuels for sustainable electricity production. Renewable and Sustainable Energy Reviews, 149, 111323. https://doi.org/10.1016/j.rser.2021.111323

- Seyam, S., Dincer, I., Agelin-Chaab, M. (2022). Economic and environmental impact assessments of hybridized aircraft engines with hydrogen and other fuels. International Journal of Hydrogen Energy, 47 (22), 11669–11685. https://doi.org/10.1016/j.ijhydene.2022.01.171

- Marchi, C. H., Araki, L. K. (2015). Evaluation of Chemical Equilibrium and Non-Equilibrium Properties for LOX/LH2 Reaction Schemes. Journal of Aerospace Technology and Management, 7 (1), 31–42. https://doi.org/10.5028/jatm.v7i1.426

- Ambrozhevich, M. V., Shevchenko, M. A. (2019). Analytical determination of isobaric heat capacity of air and combustion gases with influence of pressure and effect of thermal dissociation. Aerospace Technic and Technology, 1, 4–17. https://doi.org/10.32620/aktt.2019.1.01

- Datsenko, V., Boyko, L. (2023). Determining the influence of compressor flow path abrasive wear on the gas turbine engine characteristics. Eastern-European Journal of Enterprise Technologies, 2 (1 (122)), 12–24. https://doi.org/10.15587/1729-4061.2023.275546

- Kislov, O., Shevchenko, M. (2021). Development of a method for selecting a cruising mode and engine control program of a ramjet aircraft. Eastern-European Journal of Enterprise Technologies, 3 (3 (111)), 6–14. https://doi.org/10.15587/1729-4061.2021.233850

- Kislov, O., Ambrozhevich, M., Shevchenko, M. (2021). Development of a method to improve the calculation accuracy of specific fuel consumption for performance modeling of air-breathing engines. Eastern-European Journal of Enterprise Technologies, 2 (8 (110)), 23–30. https://doi.org/10.15587/1729-4061.2021.229515

- Dodds, W., Ekstedt, E., Bahr, D. (1983). Methanol combustion in a CF6l-80A engine combustor. 19th Joint Propulsion Conference. https://doi.org/10.2514/6.1983-1138

- Dodds, W., Ekstedt, E., Bahr, D., Fear, J. (1982). NASA/General Electric broad-specification fuels combustion technology program - Phase I results and status. 18th Joint Propulsion Conference. https://doi.org/10.2514/6.1982-1089

- Druzhinin, L. N., Shvets, L. I., Malinina, N. S. (1983). Metod i podprogramma rascheta termodinamicheskih parametrov vozduha i produktov sgoraniya uglevodorodnyh topliv. Rukovodyashchiy tehn. material aviatsionnoy tehniki. RTM 1677–83. Dvigateli aviatsionnye i gazoturbinnye.

- Isaev, S. I. (1986). Kurs himicheskoy termodinamiki. Moscow: Vysshaya shkola, 272.

- Ambrozhevich, M. V., Shevchenko, M. A. (2019). Equations of average isobaric heat capacity of air and combustion gases with influence of pressure and effect of thermal dissociation. Aerospace Technic and Technology, 2, 18–29. https://doi.org/10.32620/aktt.2019.2.02

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Mykhailo Shevchenko, Maya Ambrozhevich, Kseniia Fesenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.