Обґрунтування конструкційно-технологічних параметрів ґрунтообробних ротаційних Х-подібних робочих органів

DOI:

https://doi.org/10.15587/1729-4061.2024.309756Ключові слова:

поверхневий обробіток ґрунту, Х-подібні ротаційні робочі органи, якість розпушування ґрунтуАнотація

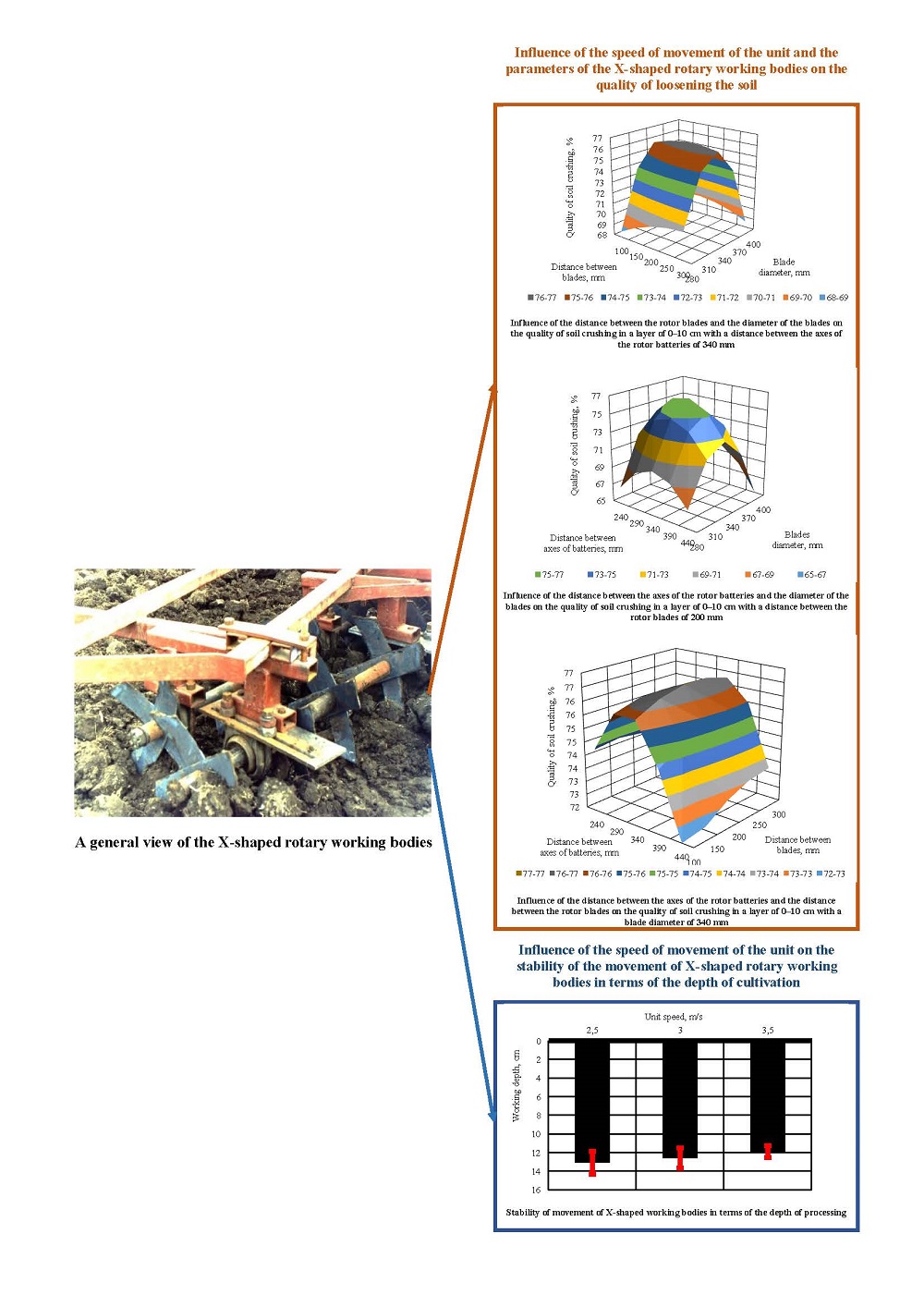

Об’єкт дослідження – процес подрібнення та кришення поверхневого шару ґрунту із дерниною озимих культур Х-подібними робочими органами. Встановлено, що використання подрібнювальної групи на базі Х-подібних ротаційних робочих органів у складі комбінованих ґрунтообробних знарядь дозволяє попередньо розпушити поверхневий шар важких ґрунтів (пересушених чи перезволожених). Встановлено, що оптимальні значення параметрів секції Х-подібних ротаційних робочих органів за якістю розпушування ґрунту в шарі 0–10 см при глибині обробітку 14±2 см залежать від швидкості руху агрегату. Так, при швидкості руху агрегату 2 м/с оптимальні значення діаметра ножа ротора становить 335,9 мм, відстань між осями батарей роторів – 316,4 мм, відстань між ножами ротора в батареї – 195,6 мм. При швидкості руху агрегату 2,5 м/с оптимальні значення цих параметрів відповідно мають значення 331,2, 325,7 та 211,3 мм, а при швидкості руху агрегату 3 м/с – 330,1, 346,8 та 106,1 мм. Також встановлено, що стабільність ходу Х-подібних робочих органів за середньоквадратичним відхиленням глибини обробітку зростає із збільшенням швидкості руху агрегату. Так, при швидкості руху агрегату 2,5 м/с середньоквадратичним відхиленням глибини обробітку ґрунту становить 1,21 см, при швидкості руху агрегату 3 м/с – 1,07 см, а при швидкості руху агрегату 3,5 м/с – 0,63 см. Також встановлено, що стабільність ходу робочих органів за глибиною обробітку зменшується із збільшенням швидкості руху агрегату. Так, при швидкості руху агрегату 2,5 м/с середня глибина обробітку ґрунту встановлюється на рівні 13,1 см, при швидкості руху агрегату 3 м/с – 12,6 см, а при швидкості руху агрегату 3,5 м/с – на рівні 11,9 см.

Посилання

- Palsaniya, D. R., Kumar, T. K., Chaudhary, M., Choudhary, M., Govindasamy, P., Prasad, M., Srinivasan, R. (2024). Tillage and mulching influence weed community dynamics and crop productivity of Sesbania alley–based food–fodder systems in rainfed agro-ecosystems. Field Crops Research, 314, 109411. https://doi.org/10.1016/j.fcr.2024.109411

- Yazıcı, A. (2024). Wear on steel tillage tools: A review of material, soil and dynamic conditions. Soil and Tillage Research, 242, 106161. https://doi.org/10.1016/j.still.2024.106161

- Mahore, V., Soni, P., Paul, A., Patidar, P., Machavaram, R. (2024). Machine learning-based draft prediction for mouldboard ploughing in sandy clay loam soil. Journal of Terramechanics, 111, 31–40. https://doi.org/10.1016/j.jterra.2023.09.002

- Getahun, G. T., Kätterer, T., Munkholm, L. J., Rychel, K., Kirchmann, H. (2022). Effects of loosening combined with straw incorporation into the upper subsoil on soil properties and crop yield in a three-year field experiment. Soil and Tillage Research, 223, 105466. https://doi.org/10.1016/j.still.2022.105466

- Agriculture » Tillage Equipment » Finland. Machinio Corp. Available at: https://www.machinio.com/tillage/finland

- Balsari, P., Biglia, A., Comba, L., Sacco, D., Eloi Alcatrão, L., Varani, M. et al. (2021). Performance analysis of a tractor - power harrow system under different working conditions. Biosystems Engineering, 202, 28–41. https://doi.org/10.1016/j.biosystemseng.2020.11.009

- Celik, A., Altikat, S. (2022). The effect of power harrow on the wheat residue cover and residue incorporation into the tilled soil layer. Soil and Tillage Research, 215, 105202. https://doi.org/10.1016/j.still.2021.105202

- Shevchenko, I. A. (2021). Agrotechnological fundamentals of creation tillage equipment. Scientific and Technical Bulletin of the Institute of Oilseed Crops NAAS, 31, 152–158. https://doi.org/10.36710//ioc-2021-31-14

- Lemken. The Agrovision Company. Available at: https://lemken.com/en-en/

- Rastra no dirigida Hankmo. Available at: https://www.agriexpo.online/es/prod/zinger-mechanisatie-bv-zibo-holland/product-170701-25932.html

- Starmixer HANKMO. Available at: https://www.agriexpo.online/tab/starmixer-hankmo.html?suggest=7462372f6e424b70687230583657786234544e337346484a42796271626865426e66694f374264516c726f3d

- Kongskilde Tillage OE. Available at: https://dineris.com.ua/sklad/category/view/60259

- Karayel, D., Šarauskis, E. (2024). Influence of tillage methods and soil crust breakers on cotton seedling emergence in silty-loam soil. Soil and Tillage Research, 239, 106054. https://doi.org/10.1016/j.still.2024.106054

- Matin, Md. A., Fielke, J. M., Desbiolles, J. M. A. (2014). Furrow parameters in rotary strip-tillage: Effect of blade geometry and rotary speed. Biosystems Engineering, 118, 7–15. https://doi.org/10.1016/j.biosystemseng.2013.10.015

- Mudarisov, S. G., Gabitov, I. I., Lobachevsky, Y. P., Mazitov, N. K., Rakhimov, R. S., Khamaletdinov, R. R. et al. (2019). Modeling the technological process of tillage. Soil and Tillage Research, 190, 70–77. https://doi.org/10.1016/j.still.2018.12.004

- Syromyatnikov, Y. N., Orekhovskaya, A. A., Dzjasheev, A.-M. S., Kalimullin, M. N., Tikhonov, E. A., Luchinovich, A. A., Bielykh, A. V. (2021). Cultivator points of the rotary tillage loosening and separating machine of the stratifier. Journal of Physics: Conference Series, 2094 (4), 042024. https://doi.org/10.1088/1742-6596/2094/4/042024

- Kumar, S. P., Tewari, V. K., Chandel, A. K., Mehta, C. R., Pareek, C. M., Chethan, C. R., Nare, B. (2023). Modelling Specific Energy Requirement for a Power-Operated Vertical Axis Rotor Type Intra-Row Weeding Tool Using Artificial Neural Network. Applied Sciences, 13 (18), 10084. https://doi.org/10.3390/app131810084

- Usaborisut, P., Prasertkan, K. (2018). Performance of combined tillage tool operating under four different linkage configurations. Soil and Tillage Research, 183, 109–114. https://doi.org/10.1016/j.still.2018.06.004

- Usaborisut, P., Prasertkan, K. (2019). Specific energy requirements and soil pulverization of a combined tillage implement. Heliyon, 5 (11), e02757. https://doi.org/10.1016/j.heliyon.2019.e02757

- Hankmo Rotary Harrows. Available at: http://www.tume.pl/uploads/pdf/Hankmo-2011-eng.pdf

- Osnovy naukovykh doslidzhen i teoriya eksperymentu (2023). Ternopil: FOP Palianytsia V.A., 186. Available at: https://elartu.tntu.edu.ua/handle/lib/40843

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Igor Shevchenko, Gennadii Golub, Nataliya Tsyvenkova, Iryna Shevchenko, Liudmyla Titova, Ivan Omarov, Olena Sukmaniuk, Volodymyr Kulykivskyi, Viktor Borovskyi, Maksym Zayets

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.