Design of hydraulic motors with rotary shaft movement for driving working equipment in modern machines

DOI:

https://doi.org/10.15587/1729-4061.2024.309759Keywords:

hydraulic drive, earthmoving and construction machines, low-speed motors, valve distributors, power cylindersAbstract

The object of research is the processes in hydraulic motors based on power cylinders, designed to drive the shaft of the working equipment in modern machines into rotational motion.

When using standard motors, a problem arises relating to the need to introduce additional devices into the structure of the mechanisms of modern machines. Such devices are aimed at matching the rotation frequency of the motor shaft with the rotation shaft of the working equipment of these machines. Such a device is a reducer, the use of which leads to the appearance of a number of disadvantages. Their elimination is achieved by using the results of this study.

The reported results differ from standard motors that are mass-produced, in that, based on research, motors with a rotation frequency of its shaft in the range from zero to two hundred and more revolutions per minute are proposed, which is not realized by known motors. This testifies to the construction of motors based on power cylinders, which make it possible to realize this range of rotation frequencies of its shaft.

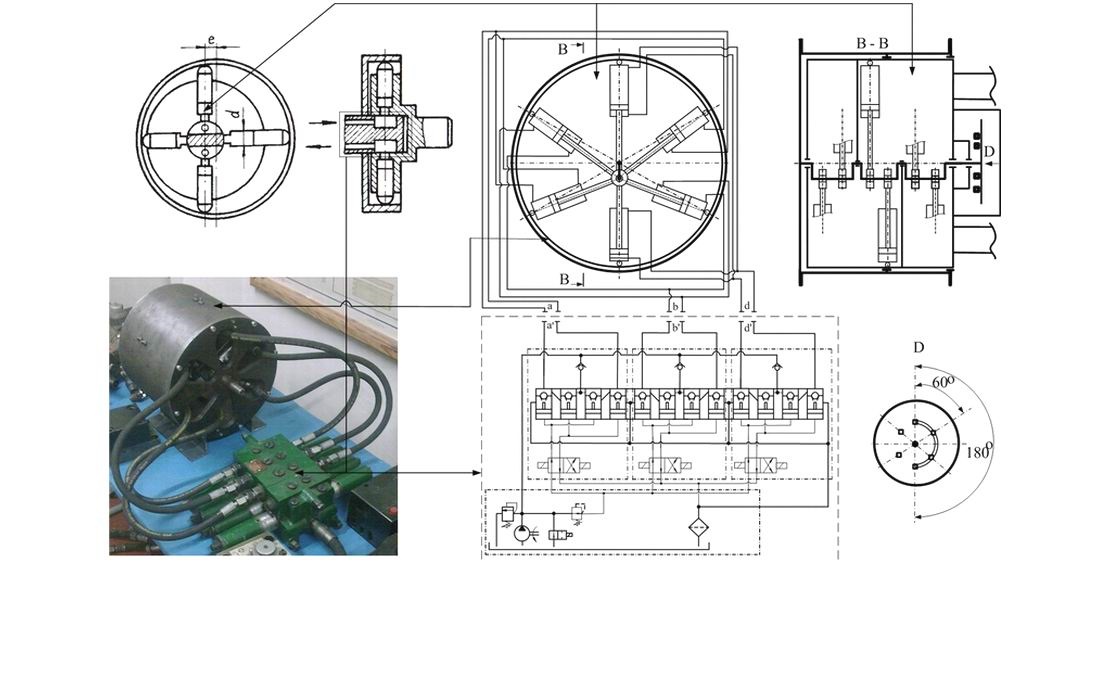

The special and distinctive features of the results are based on the application of the principle of disintegration of motor elements into two functional components. One of them includes power cylinders with a crankshaft, and the second one includes the distribution system of the working fluid.

The motor implementation went through the stages of designing computer and physical models and devising schematic solutions. Calculation dependences were obtained to determine the main design parameters, according to which the motor was manufactured in the form of a full-scale sample.

The scope and conditions of practical use refer to machines with working equipment capable of functioning under a mode with a low rotation frequency and a significant torque on the motor shaft

References

- Remarchuk, M., Chmuzh, Y., Orel, Y., Halytskyi, O., Kebko, O., Kutsenko, O. (2020). Determination of the condition of crane mechanisms for lifting loads under the conditions of operation according to the results of their diagnostics. Sworld-Us Conference Proceedings, usc17-01, 3–8. https://doi.org/10.30888/2709-2267.2023-17-01-002

- Panchenko, A., Voloshina, A., Milaeva, I., Panchenko, I., Titova, O. (2018). The Influence of the form Error after Rotor Manufacturing on the Output Characteristics of an Orbital Hydraulic Motor. International Journal of Engineering & Technology, 7 (4.3), 1. https://doi.org/10.14419/ijet.v7i4.3.19542

- Panchenko, A., Voloshina, A., Panchenko, I., Titova, O., Pastushenko, A. (2019). Reliability design of rotors for orbital hydraulic motors. IOP Conference Series: Materials Science and Engineering, 708 (1), 012017. https://doi.org/10.1088/1757-899x/708/1/012017

- Pandey, A. K., Kumar, A., Tripathi, J. P., Ehtesham Hasan, Md. (2023). Analysis of a high speed low-torque variable displacement hydro-motor efficiency at different displacement conditions. Materials Today: Proceedings, 79, 247–249. https://doi.org/10.1016/j.matpr.2022.11.114

- Yang, L., Nie, S., Yin, S., Zhao, J., Yin, F. (2015). Numerical and experimental investigation on torque characteristics of seawater hydraulic axial piston motor for underwater tool system. Ocean Engineering, 104, 168–184. https://doi.org/10.1016/j.oceaneng.2015.05.003

- Kumar Singh, U., Tripathi, J. P., Khanna, K. (2022). Effect of pump leakage on slip and pressure loss in a hydraulic cylinder drive. Materials Today: Proceedings, 63, 573–578. https://doi.org/10.1016/j.matpr.2022.04.033

- Kindrachuk, M., Radionenko, O., Kryzhanovskyi, A., Marchuk, V. (2014). The Friction Mechanism Between Surfaces With Regular Micro Grooves Under Boundary Lubrication. Aviation, 18 (2), 64–71. https://doi.org/10.3846/16487788.2014.926642

- Yeremenko, R. (2024). The Impact of Hydraulic System Pressure Changes on the Dynamic Properties of a Hydraulic Actuator. Mechanics and Advanced Technologies, 8 (2 (101)), 157–163. https://doi.org/10.20535/2521-1943.2024.8.2(101).303015

- Remarchuk, M. P. (2006). Hidromekhanichnyi i zahalnyi KKD «hidromotora-koleso» mekhanizmu peremishchennia tykhokhidnoi mashyny, 35, 174–183.

- Nesterov, A. P., Rozenfel'd, N. V., Yaryzhko, A. V., Vysotskiy, G. V., Gulenko, A. S. (2005). Eksperimental'noe issledovanie obemnogo kulisnogo gidroprivoda. Naukovyi visnyk budivnytstva, 32, 107–111.

- Leusenko, A. V., Vysotskyi, H. V., Remarchuk, M. P., Hulenko, O. S., Nesterov, A. P., Kyrychenko, I. H. (2003). Pat. No. 74601 UA. Hidromekhanichnyi pryvid hirnychoi mashyny. No. 2003065556; declareted: 17.06.2003; published: 16.01.2006. Available at: https://uapatents.com/5-74601-gidromekhanichnijj-privid-girnicho-mashini.html

- Samsonkin, V. N. (2008). Sistemniy podhod, kak osnovopolagayuschiy metod issledovaniya ergonomiki: suschnost', primenenie v transportnyh sistemah. Zaliznychnyi transport Ukrainy, 6, 3–4.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Nikolaj Remarchuk, Serhii Voronin, Yaroslav Chmuzh, Andrii Yevtushenko, Oleg Halytskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.