Оптимізація невизначеності вимірювань на координатно-вимірювальній машині при контролі складних геометричних поверхонь

DOI:

https://doi.org/10.15587/1729-4061.2024.310051Ключові слова:

координатно-вимірювальна машина, оптимізація невизначеності, складні геометричні поверхні, адаптивна стратегія вимірювання, невизначеність вимірювання, метод Монте-Карло, контроль якості, промислова метрологія, автоматизація вимірювань, високоточне виробництвоАнотація

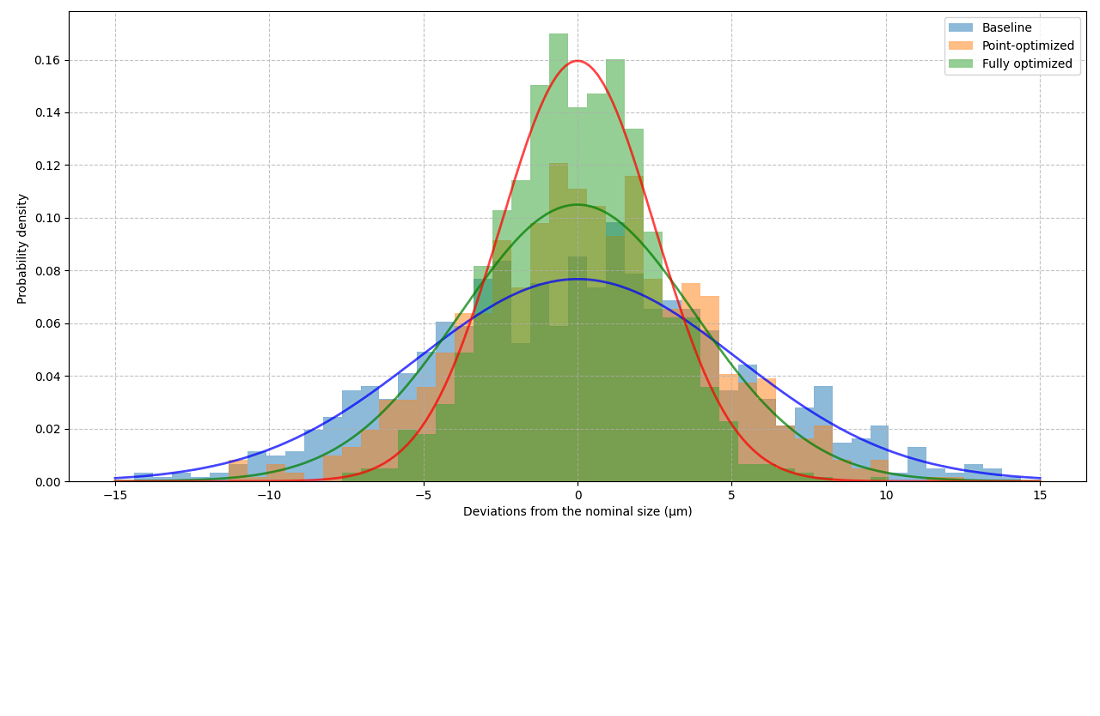

Об'єктом дослідження є процес оптимізації невизначеності вимірювань на координатно-вимірювальній машині (КВМ) при контролі складних геометричних поверхонь. Вирішувалась проблема недостатньої точності та ефективності вимірювань складних деталей на КВМ в умовах виробництва. Розроблено метод оптимізації невизначеності вимірювань, що включає математичну модель процесу вимірювання та адаптивний алгоритм оптимізації стратегії контролю, на основі методу Монте-Карло. Модель враховує геометрію поверхонь та характеристики КВМ, а алгоритм динамічно коригує параметри вимірювання. Результати демонструють зниження невизначеності вимірювань на 15–20 % та скорочення часу контролю на 10–12 % порівняно з традиційними методами. Це досягається завдяки врахуванню специфіки геометрії складних поверхонь та адаптивному підходу.

Унікальність розробленого методу полягає в його здатності автоматично адаптуватися до різних типів КВМ та вимірюваних об'єктів, оптимізуючи кількість і розташування точок вимірювання, швидкість руху щупа та силу його контакту з поверхнею. Метод враховує не лише геометричні параметри об'єктів, але й характеристики самої КВМ, що дозволяє досягти високої точності. Метод особливо ефективний для деталей зі складною геометрією, де традиційні методи часто призводять до значних похибок.

Практичне застосування можливе на машинобудівних підприємствах при контролі якості складних деталей, особливо в серійному виробництві. Впровадження розробленого методу дозволяє підвищити якість продукції та знизити виробничі витрати на 8–10 % за рахунок оптимізації процесу контролю та зменшення браку

Посилання

- Liao, Z.-Y., Wang, Q.-H., Xu, Z.-H., Wu, H.-M., Li, B., Zhou, X.-F. (2024). Uncertainty-aware error modeling and hierarchical redundancy optimization for robotic surface machining. Robotics and Computer-Integrated Manufacturing, 87, 102713. https://doi.org/10.1016/j.rcim.2023.102713

- Ziętarski, S., Kachel, S., Benaouali, A. (2016). Coordinate measuring machine uncertainty analysis using the combinatorial cyclic method of optimization. Mechanik, 7, 876–877. https://doi.org/10.17814/mechanik.2016.7.216

- Zhao, X., Ji, L., Zhao, L. (2018). Calibration of Parallelism Error About Rotating Shafts Based on the Three-coordinate Measuring Machine. Proceedings of the 2nd International Conference on Intelligent Manufacturing and Materials. https://doi.org/10.5220/0007532203790383

- Shen, M., Yang, H., Chang, D., Jiang, X., Hu, Y. (2024). Dynamic error modeling and analysis of articulated arm coordinate measuring machine with integrated joint module. Measurement Science and Technology, 35 (6), 065022. https://doi.org/10.1088/1361-6501/ad35de

- Cheung, C., Ren, M., Kong, L., Whitehouse, D. (2014). Modelling and analysis of uncertainty in the form characterization of ultra-precision freeform surfaces on coordinate measuring machines. CIRP Annals, 63 (1), 481–484. https://doi.org/10.1016/j.cirp.2014.03.032

- Zhuang, Q., Wan, N., Guo, Y., Zhu, G., Qian, D. (2024). A state-of-the-art review on the research and application of on-machine measurement with a touch-trigger probe. Measurement, 224, 113923. https://doi.org/10.1016/j.measurement.2023.113923

- Wojtyła, M., Rosner, P., Płowucha, W., Forbes, A. B., Savio, E., Balsamo, A. (2022). Validation of the sensitivity analysis method of coordinate measurement uncertainty evaluation. Measurement, 199, 111454. https://doi.org/10.1016/j.measurement.2022.111454

- Zhang, M., Liu, D., Liu, Y. (2024). Recent progress in precision measurement and assembly optimization methods of the aero-engine multistage rotor: A comprehensive review. Measurement, 235, 114990. https://doi.org/10.1016/j.measurement.2024.114990

- Wozniak, A., Krajewski, G., Byszewski, M. (2019). A new method for examining the dynamic performance of coordinate measuring machines. Measurement, 134, 814–819. https://doi.org/10.1016/j.measurement.2018.12.041

- Hu, Y., Zhao, R., Ju, B. (2021). Geometric analysis of measurement errors in a surface metrology class with closed-loop probes. Measurement, 184, 109869. https://doi.org/10.1016/j.measurement.2021.109869

- Yan, Y., He, G., Sang, Y., Yao, C., Wang, S., Chen, F. (2022). A two-module automated scanning inspection planning methodology for complex surfaces on coordinate measuring machine. Measurement, 202, 111827. https://doi.org/10.1016/j.measurement.2022.111827

- Xing, T., Zhao, X., Song, L., Cui, Z., Zou, X., Sun, T. (2022). On-machine measurement method and geometrical error analysis in a multi-step processing system of an ultra-precision complex spherical surface. Journal of Manufacturing Processes, 80, 161–177. https://doi.org/10.1016/j.jmapro.2022.05.057

- Sato, O., Takatsuji, T., Matsuzaki, K., Watanabe, M., Kajima, M., Miura, Y., Nakanishi, S. (2024). Practical experimental design and uncertainty evaluation method for dimensional and form measurements using coordinate measuring machines. Measurement, 227, 114224. https://doi.org/10.1016/j.measurement.2024.114224

- Ren, M., Cheung, C., Kong, L., Wang, S. (2015). Quantitative Analysis of the Measurement Uncertainty in Form Characterization of Freeform Surfaces Based on Monte Carlo Simulation. Procedia CIRP, 27, 276–280. https://doi.org/10.1016/j.procir.2015.04.078

- Wang, Z., He, X., Wang, Y. (2021). Different measuring methods of REVO five-axis coordinate measuring machine. Tenth International Symposium on Precision Mechanical Measurements. https://doi.org/10.1117/12.2613428

- Internet-Based Surface Metrology Algorithm Testing System. National Institute of Standards and Technology. Available at: https://physics.nist.gov/VSC/jsp/About.jsp

- D Metrology Use Cases. GOM GmbH.

- Example Studies. Digital Surf. Available at: https://www.digitalsurf.com/

- An opensource on-machine 3D Scanner CMM (Coordinate Measuring Machine) system. OpenCMM. Available at: https://github.com/OpenCMM/OpenCMM

- Sousa, A. R. (2018). Metrological evaluation of a Coordinate Measuring Machine with 5-axis measurement technology. Procedia CIRP, 75, 367–372. https://doi.org/10.1016/j.procir.2018.04.035

- Nasir, S. S. M., Hussin, N., Fohimi, N. A. M., Ibrahim, D., Wahab, R. M. (2023). Design Improvement and Fabrication of a Jig for Holding a Workpiece in a Coordinate Measuring Machine. Progress in Engineering Technology V, 197–206. https://doi.org/10.1007/978-3-031-29348-1_21

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Volodymyr Kvasnikov, Oleg Chalyi, Maryna Graf, Anatolii Perederko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.