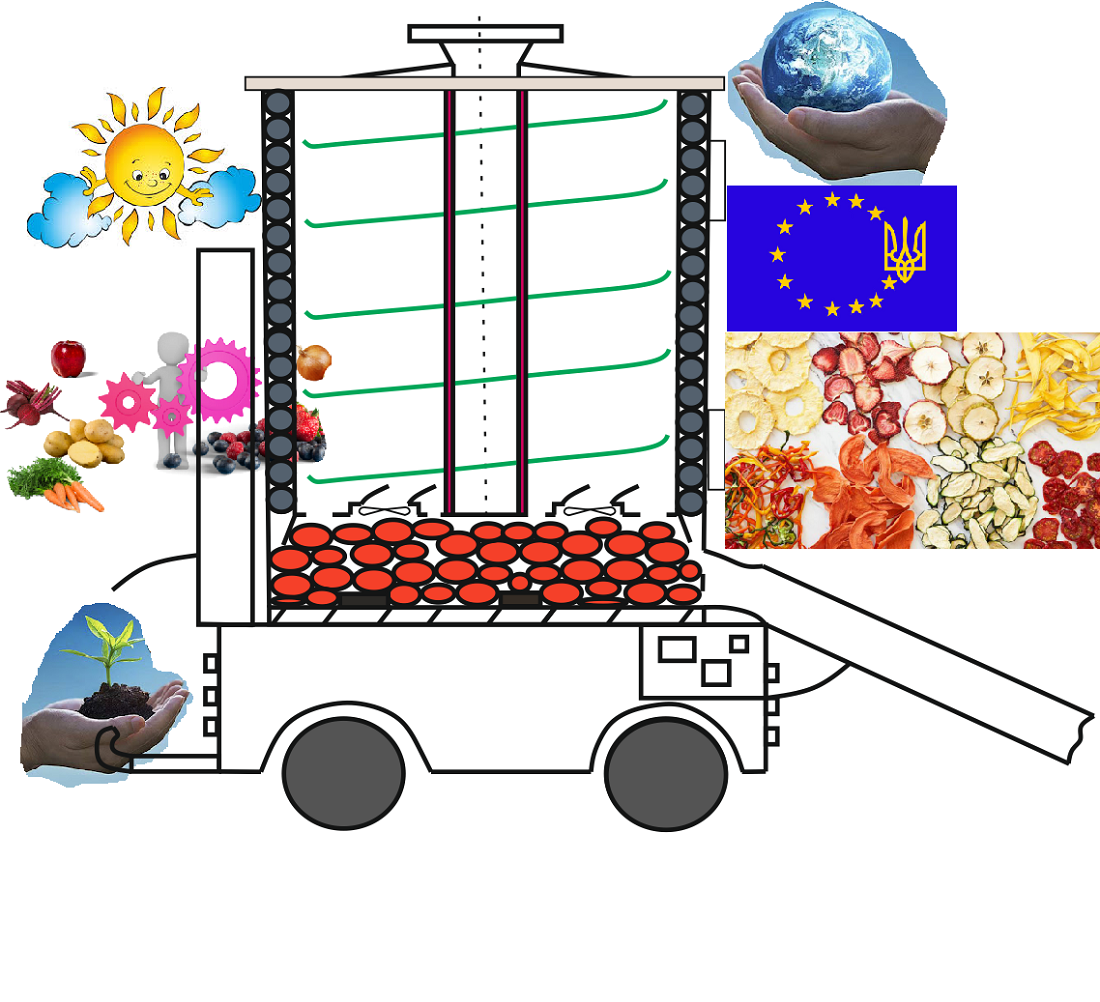

Improving the mobile structure of a vertical modular solar dryer for the agricultural sector "From field to fork"

DOI:

https://doi.org/10.15587/1729-4061.2025.323607Keywords:

solar dryer, mobility, agricultural raw materials, hemispherical collectors, thermal accumulator, autonomous fans, competitiveness, export potentialAbstract

The object of this study is the radiation drying of local agricultural raw materials (Jerusalem artichoke of the "Kyivskyi bily" variety and apples of the "Williams" variety) in a mobile structure of a vertical-modular solar dryer. The study is aimed at improving the resource-saving drying of agricultural raw materials. The solar dryer has adjustable hemispherical air collectors (tilt angle 20…45°) and a heat-insulated chamber with a thermal accumulator (stone pebbles, size 50–80 mm), a backup infrared heater (600 W), and autonomous fans in a combination with Peltier elements. Drying of agricultural raw materials with a thickness of 4–12 mm and a heat carrier speed of 0.05–2.0 m/s was carried out in the summer-autumn decades of 2024. The drying duration of Jerusalem artichoke was 38.6–50 h, apples – 30.5…37 h; drying temperature – 22…50 °C. Moisture removal was 77.8 % for Jerusalem artichoke and 87.0 % for apples. Moisture removal when loading 6.0 kg of raw materials was 3.5 kg for Jerusalem artichoke (77.8 % moisture) and 4.2 kg for apples (87.0 % moisture) under drying conditions to a moisture content of 20.0 %. Losses of vitamin C during sun drying in Jerusalem artichoke were 2.17 times (versus 3.21 times during convective drying), and in apples – 2.26 times (versus 2.58 times). Dietary fiber in Jerusalem artichoke decreased by 2.29 times (versus 3.33 times), and in apples – by 2.25 times (versus 3.91 times). Losses of β-carotene in Jerusalem artichoke during sun drying were 2.65 times (versus 3.08 times). There was also a smaller decrease in phosphorus and mono- and disaccharides. Dried semi-finished products had a uniform appearance, light yellow color, and natural taste and aroma properties. An improved mechanism for managing the competitiveness of agricultural enterprises combines technical, economic, and organizational aspects for entering the European market and expanding exports

References

- Farm to Fork strategy. European Commission. Available at: https://food.ec.europa.eu/horizontal-topics/farm-fork-strategy_en

- Mamchur, V., Studinska, G. (2023). Innovative development of the agrarian sphere under the conditions of the implementation of the national system of sustainability. Economy and Society, 56. https://doi.org/10.32782/2524-0072/2023-56-144

- Savchuk, Ye. V. (2019). Perspektyvy rozvytku soniachnoiy enerhetyky Ukraiyny. World Science, 3 (6 (46)), 42–44. https://doi.org/10.31435/rsglobal_ws/30062019/6575

- Abdul Razak, A., Tarminzi, M. A. S. M., Azmi, M. A. A., Ming, Y. H., Akramin, M., Mokhtar, N. (2021). Recent advances in solar drying system: A Review. International Journal of Engineering Technology and Sciences, 8 (1), 1–13. https://doi.org/10.15282/ijets.8.1.2021.1001

- Klymenko, N., Voronenko, I., Nehrey, M., Rogoza, K., Rogoza, N. (2023). Risk assessment of shock periods and investment attractiveness of agroholdings of Ukraine. Agricultural and Resource Economics: International Scientific E-Journal, 9 (2). https://doi.org/10.51599/are.2023.09.02.07

- Zahorulko, A., Zagorulko, A., Minenko, S., Bozhydai, I. (2024). Scientific and practical justification of innovative approaches to production of multicomponent semi-finished products for food products in the conditions of food security of the country. Food Production: Innovative Technological Solutions. Kharkiv: TECHNOLOGY CENTER PC, 64–91. Available at: http://monograph.com.ua/pctc/catalog/book/978-617-7319-99-2.ch3

- Kherrafi, M. A., Benseddik, A., Saim, R., Bouregueba, A., Badji, A., Nettari, C., Hasrane, I. (2024). Advancements in solar drying technologies: Design variations, hybrid systems, storage materials and numerical analysis: A review. Solar Energy, 270, 112383. https://doi.org/10.1016/j.solener.2024.112383

- Sharma, A., Chen, C. R., Vu Lan, N. (2009). Solar-energy drying systems: A review. Renewable and Sustainable Energy Reviews, 13 (6-7), 1185–1210. https://doi.org/10.1016/j.rser.2008.08.015

- Koshta, V., Patel, H., Mudgil, D. (2021). CHAPTER 17 Solar Energy in Food Processing. Available at: https://www.researchgate.net/publication/348590762_CHAPTER_17_Solar_Energy_in_Food_Processing

- Pandey, S., Kumar, A., Sharma, A. (2024). Sustainable solar drying: Recent advances in materials, innovative designs, mathematical modeling, and energy storage solutions. Energy, 308, 132725. https://doi.org/10.1016/j.energy.2024.132725

- Anderson, C. B., Picotti, G., Schmidt, T., Cholette, M. E., Bern, G., Steinberg, T. A., Manzolini, G. (2024). The impact of condensation on solar collector soiling: An experimental study. Solar Energy Materials and Solar Cells, 275, 112998. https://doi.org/10.1016/j.solmat.2024.112998

- Ikrang, E. G., Whyte, A. A., Maurice, A. M., Akubuo, C. O., Onwude, D. I. (2017). Design and fabrication of a direct passive solar dryer for tilapia fish filets. Acta Horticulturae, 1152, 63–70. https://doi.org/10.17660/actahortic.2017.1152.9

- Tuncer, A. D., Amini, A., Khanlari, A. (2023). Developing an infrared-assisted solar drying system using a vertical solar air heater with perforated baffles and nano-enhanced black paint. Solar Energy, 263, 111958. https://doi.org/10.1016/j.solener.2023.111958

- Heydari, A. (2022). Experimental analysis of hybrid dryer combined with spiral solar air heater and auxiliary heating system: Energy, exergy and economic analysis. Renewable Energy, 198, 1162–1175. https://doi.org/10.1016/j.renene.2022.08.110

- Chanda, P. R., Podder, B., Biswas, A., Sengupta, A. R. (2023). Advancements in solar assisted drying technologies: A comprehensive review post 2017. Journal of Stored Products Research, 104, 102190. https://doi.org/10.1016/j.jspr.2023.102190

- Shekata, G. D., Tibba, G. S., Baheta, A. T. (2024). Recent advancements in indirect solar dryer performance and the associated thermal energy storage. Results in Engineering, 24, 102877. https://doi.org/10.1016/j.rineng.2024.102877

- Hadibi, T., Boubekri, A., Mennouche, D., Benhamza, A., Kumar, A., Bensaci, C., Xiao, H.-W. (2022). Effect of ventilated solar-geothermal drying on 3E (exergy, energy, and economic analysis), and quality attributes of tomato paste. Energy, 243, 122764. https://doi.org/10.1016/j.energy.2021.122764

- Rahman, M. A., Hasnain, S. M. M., Paramasivam, P., Zairov, R., Ayanie, A. G. (2025). Solar Drying for Domestic and Industrial Applications: A Comprehensive Review of Innovations and Efficiency Enhancements. Global Challenges, 9 (2). https://doi.org/10.1002/gch2.202400301

- Villagran, E., Espitia, J. J., Velázquez, F. A., Rodriguez, J. (2024). Solar Dryers: Technical Insights and Bibliometric Trends in Energy Technologies. AgriEngineering, 6 (4), 4041–4063. https://doi.org/10.3390/agriengineering6040228

- Kolosok, S., Lyeonov, S., Voronenko, I., Goncharenko, O., Maksymova, J., Chumak, O. (2022). Sustainable Business Models and IT Innovation: The Case of the REMIT. Journal of Information Technology Management, 14, 147–156. https://doi.org/10.22059/jitm.2022.88894

- Olokor, J., Oghenekaro, Omojowo, F., Samuel (2009). Adaptation And Improvement Of A Simple Solar Tent Dryer To Enhance Fish Drying. Nature and Science of Sleep, 7 (10). Available at: https://www.researchgate.net/publication/274370310_Adaptation_And_Improvement_Of_A_Simple_Solar_Tent_Dryer_To_Enhance_Fish_Drying

- EL-Mesery, H. S., EL-Seesy, A. I., Hu, Z., Li, Y. (2022). Recent developments in solar drying technology of food and agricultural products: A review. Renewable and Sustainable Energy Reviews, 157, 112070. https://doi.org/10.1016/j.rser.2021.112070

- Kafetzis, A., Ziogou, C., Panopoulos, K. D., Papadopoulou, S., Seferlis, P., Voutetakis, S. (2020). Energy management strategies based on hybrid automata for islanded microgrids with renewable sources, batteries and hydrogen. Renewable and Sustainable Energy Reviews, 134, 110118. https://doi.org/10.1016/j.rser.2020.110118

- Zahorulko, A., Zagorulko, A., Mykhailov, V., Ibaiev, E. (2021). Improved rotary film evaporator for concentrating organic fruit and berry puree. Eastern-European Journal of Enterprise Technologies, 4 (11 (112)), 92–98. https://doi.org/10.15587/1729-4061.2021.237948

- Minenko, S., Cherevko, O., Skrynnik, V., Tesliuk, H., Bondar, M., Skoromna, O. et al. (2023). Improvement of the vacuum evaporator for the production of paste-like semi-finished products with a high degree of readiness. Eastern-European Journal of Enterprise Technologies, 5 (11 (125)), 76–83. https://doi.org/10.15587/1729-4061.2023.288896

- Zahorulko, A., Cherevko, O., Zagorulko, A., Yancheva, M., Budnyk, N., Nakonechna, Y. et al. (2021). Design of an apparatus for low-temperature processing of meat delicacies. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 6–12. https://doi.org/10.15587/1729-4061.2021.240675

- Zahorulko, A., Zagorulko, A., Savytska, N., Minenko, S., Pugach, A., Ponomarenko, N. et al. (2023). Design of a universal apparatus for heat treatment of meat and vegetable cooked and smoked products with the addition of dried semi-finished products of a high degree of readiness to the recipe. Eastern-European Journal of Enterprise Technologies, 4 (11 (124)), 73–82. LOCKSS. https://doi.org/10.15587/1729-4061.2023.285406

- Slobodniuk, R. Ye., Horalchuk, A. B. (2018). Analitychna khimiya ta analiz kharchovoi produktsiyi. Kyiv: VD «Kondor», 336.

- Ladyka, V. I., Shylman, L. Z., Pertsevoi, F. V. et al. (2021). Metodolohiya naukovykh doslidzhen. Kherson: OLDI-PLIuS, 222. Available at: https://repo.btu.kharkov.ua/bitstream/123456789/8269/1/NP_Metodolohiya_21.pdf

- Zahorulko, A. M., Zahorulko, O. Ye. (2021). Pat. No. 149981 UA. Plivkopodibnyi rezystyvnyi elektronahrivach vyprominiuiuchoho typu. No. u202102839; declareted: 28. 05.2021; published: 23.12.2021.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Andrii Zahorulko, Iryna Voronenko, Sofiia Minenko, Andrii Pugach, Оlena Nazarenko, Olesya Lebedenko, Eldar Ibaiev, Nataliia Tytarenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.