Developing moсhi frozen desserts technology using by-products of juice production

DOI:

https://doi.org/10.15587/1729-4061.2025.324602Keywords:

frozen desserts, gluten-free products, pomace, guar gum, xanthan gumAbstract

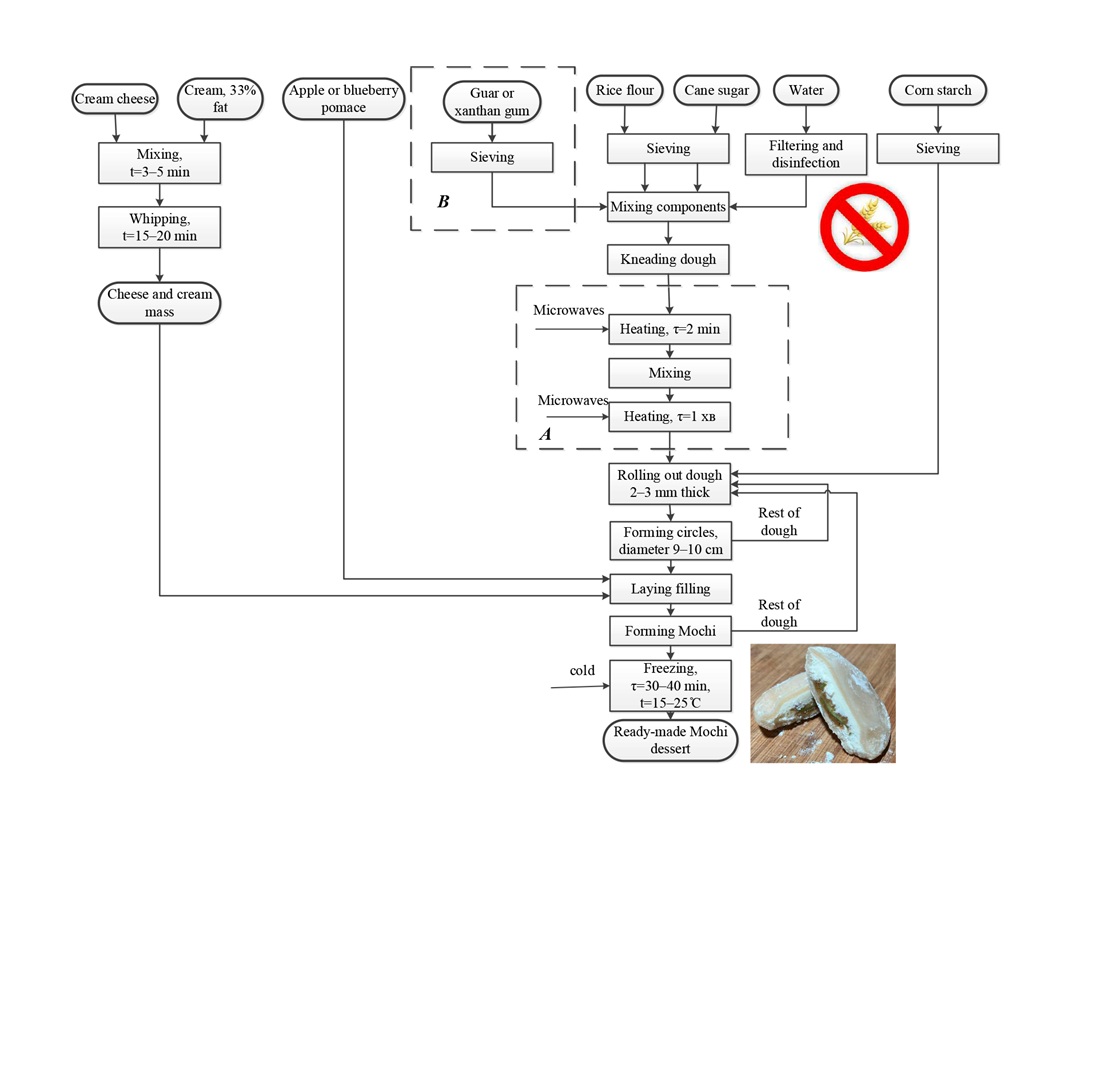

The object of this study is the production of frozen Mochi desserts. A significant problem of our time is the spread of congenital food-borne diseases and the accumulation of waste and by-products of food production, which pollute the environment. These problems significantly reduce the list of products that can be consumed by humans and require additional solutions for the processing of by-products. Devising the recipe and technology of Mochi desserts could make it possible to solve these problems.

The effectiveness of using guar gum in the production of dessert dough in an amount of 10–30 % of the mass of rice flour has been proven. The guar gum solution has a viscosity of 0.34 Pa×s. Due to this, the dough is formed faster and has a stronger structure. Such a solution makes it possible to freeze and thaw products up to 7 times without loss of quality. When xanthan gum is added, the dough is not stable at freezing temperatures: after thawing, it becomes sticky and watery. This indicates an increase in the phenomenon of syneresis.

It has been found that the content of dry matter, fiber, and pectin substances in apple and blueberry juices is 22.3 %, 10.5 %, and 6.3 %, and 11.3 %, 16.2 %, and 1.6 %, respectively. The activity of lipase, lipoxygenase, and catalase enzymes in the specified raw materials is as follows: –0.26 conditional units, –0.004 ΔPV and 98.43 units of activity and –2.8 conditional units, –0.02 ΔPV and 1.43 units of activity. Such results are explained by the chemical composition of the raw materials and may indicate their antioxidant properties.

The results have practical significance for catering enterprises and those that manufacture frozen products. In addition, they could make it possible to increase the profitability of production through the use of by-products. The products devised have health benefits, can be consumed by people with celiac disease, and have added value due to the integrated processing of raw materials

References

- Caio, G., Riegler, G., Patturelli, M., Facchiano, A., De Magistris, L., Sapone, A. (2017). Pathophysiology of non-celiac gluten sensitivity: where are we now? Minerva Gastroenterology, 63 (1). https://doi.org/10.23736/s1121-421x.16.02346-1

- Sharma, N., Bhatia, S., Chunduri, V., Kaur, S., Sharma, S., Kapoor, P. et al. (2020). Pathogenesis of Celiac Disease and Other Gluten Related Disorders in Wheat and Strategies for Mitigating Them. Frontiers in Nutrition, 7. https://doi.org/10.3389/fnut.2020.00006

- Senatorova, G., Omelchenko, O., Teslenko, T., Muratov, G., Orlova, N., Chatykian, K. (2023). Challenges in differential diagnosis of coeliac disease and gluten intolerance in children. Neonatology, Surgery and Perinatal Medicine, 13 (2 (48)), 61–70. https://doi.org/10.24061/2413-4260.xiii.2.48.2023.9

- Afanasiuk, O., Shmaliy, V., Yakovets, O. (2022). Klinichnyi vypadok tseliakiyi u doroslykh. Grail of Science, 14-15, 584–589. https://doi.org/10.36074/grail-of-science.27.05.2022.105

- Hubska, O. Yu. (2019). Oberezhno – hliuten! Shcho neobkhidno znaty pro tseliakiyu? Available at: https://health-ua.com/article/41194-oberezhnoglyuten--sho-neobhdno-znati-pro-tcelakyu

- Samokhvalova, O., Kucheruk, Z., Kasabova, K., Oliinyk, S., Shmatchenko, N. (2021). Effect of microbial polysaccharides on the quality indicators of protein-free and gluten-free products during storage. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 61–68. https://doi.org/10.15587/1729-4061.2021.225003

- Šmídová, Z., Rysová, J. (2022). Gluten-Free Bread and Bakery Products Technology. Foods, 11 (3), 480. https://doi.org/10.3390/foods11030480

- Muadklay, J., Charoenrein, S. (2008). Effects of hydrocolloids and freezing rates on freeze–thaw stability of tapioca starch gels. Food Hydrocolloids, 22 (7), 1268–1272. https://doi.org/10.1016/j.foodhyd.2007.06.008

- Giura, L., Urtasun, L., Ansorena, D., Astiasarán, I. (2022). Effect of freezing on the rheological characteristics of protein enriched vegetable puree containing different hydrocolloids for dysphagia diets. LWT, 169, 114029. https://doi.org/10.1016/j.lwt.2022.114029

- Boča, S., Galoburda, R., Skrupskis, I., Skrupska, D. (2014). The Effect of Freezing and Hydrocolloids on the Physical Parameters of Strawberry Mass-Based Desserts. Proceedings of the Latvia University of Agriculture, 31 (1), 12–24. https://doi.org/10.2478/plua-2014-0002

- Alija, J., Talens, C. (2012). New concept of desserts with no added sugar. International Journal of Gastronomy and Food Science, 1 (2), 116–122. https://doi.org/10.1016/j.ijgfs.2013.06.002

- Lapytska, N., Syza, O., Gorodyska, O., Savchenko, O., Rebenok, E. (2023). Improving the jelly plum juice technology by using secondary products of oil production. Eastern-European Journal of Enterprise Technologies, 3 (11 (123)), 68–77. https://doi.org/10.15587/1729-4061.2023.281929

- Kowalski, S., Gumul, D. (2024). The Use of Waste Products from the Food Industry to Obtain High Value-Added Products. Foods, 13 (6), 847. https://doi.org/10.3390/foods13060847

- Lapytska, Н., Biloborodko, А. (2024). Development of shot technology using by-products of juice production. Biota. Human. Technology, 3, 160–169. https://doi.org/10.58407/bht.3.24.9

- Khomych, G. P., Nakonechna, Yu. G., Oliynyk, L. B., Gaivoronska, Z. M., Nakonechnyy, K. R. (2024). Use of juice production waste in food technology. Scientific Messenger of LNU of Veterinary Medicine and Biotechnologies, 26 (101), 127–134. https://doi.org/10.32718/nvlvet-f10119

- Manual of methods of analysis of foods. Fruit and vegetable products (2015). Food safety and standards authority of India Ministry of health and family welfare government of India. New Delhi. Available at: https://fssai.gov.in/upload/uploadfiles/files/FRUITS_AND_VEGETABLE.pdf

- Shelukhina, N. P., Fedichkina, L. G. (1994). A rapid method for quantitative determination of pectic substances. Acta Botanica Neerlandica, 43 (2), 205–207. https://doi.org/10.1111/j.1438-8677.1994.tb00745.x

- Horalchuk, A. B., Pyvovarov, P. P., Hrynchenko, O. O., Pohozhykh, M. I., Polevych, V. V., Hurskyi, P. V. (2006). Reolohichni metody doslidzhennia syrovyny i kharchovykh produktiv ta avtomatyzatsiya rozrakhunkiv reolohichnykh kharakterystyk. Kharkiv, 63. Available at: https://www.researchgate.net/profile/Andrii-Goralchuk/publication/282649472_Rheological_methods_of_raw_foods_and_automation_of_payments_rheological_characteristics/links/5615678208ae4ce3cc6533c3/Rheological-methods-of-raw-foods-and-automation-of-payments-rheological-characteristics.pdf

- Drobot, V. I. (2019). Dovidnyk z tekhnolohiyi khlibopekarskoho vyrobnytstva. Kyiv, 580.

- Vozhegova, R. A., Borovik, V. O., Grabovsky, M. B., Marchenko, T. Yu., Grabovskaya, T. O. (2022). Niche cultures – new opportunities for the agro-industrial complex of Ukraine. Agrarian innovations, 13, 181–189. https://doi.org/10.32848/agrar.innov.2022.13.27

- Demchenko, V. G., Konyk, A. V., Khomenko, M. (2022). Mobile technology complex for the preparation of water-soluble polymers. Scientific Works, 86 (1), 125–132. https://doi.org/10.15673/swonaft.v86i1.2414

- Simkova, K., Grohar, M. C., Pelacci, M., Veberic, R., Jakopic, J., Hudina, M. (2024). The Effect of Freezing, Frozen Storage and Thawing on the Strawberry Fruit Composition. International Journal of Fruit Science, 24 (1), 186–199. https://doi.org/10.1080/15538362.2024.2355920

- Alinovi, M., Mucchetti, G. (2020). Effect of freezing and thawing processes on high-moisture Mozzarella cheese rheological and physical properties. LWT, 124, 109137. https://doi.org/10.1016/j.lwt.2020.109137

- Sawano, M., Masuda, H., Iyota, H., Shimoyamada, M. (2021). Melting Characteristics of Ice Cream Prepared with Various Agitation Speeds in Batch Freezer. Chemical Engineering Transactions, 87, 337–342. http://doi.org/10.3303/CET2187057

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Nadiia Lapytska, Yevhen Rebenok, Olga Syza, Oleksii Shkliaiev, Аnna Novik, Tamara Lystopad, Ivan Haliasnyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.