Визначення фінансово-економічних переваг комплексного використання мінеральної сировини на підприємстві

DOI:

https://doi.org/10.15587/1729-4061.2025.325419Ключові слова:

фінансово-економічні переваги, комплексне використання мінеральної сировини, ресурсозбереження, диверсифікація, гірничодобувна промисловістьАнотація

Об’єктом дослідження є фінансово-економічні показники комплексного використання мінеральної сировини на підприємстві. Вирішено проблему економічного обґрунтування доцільності комплексного використання мінеральної сировини на мікроекономічному рівні, що є актуальною для створення зеленої економіки.

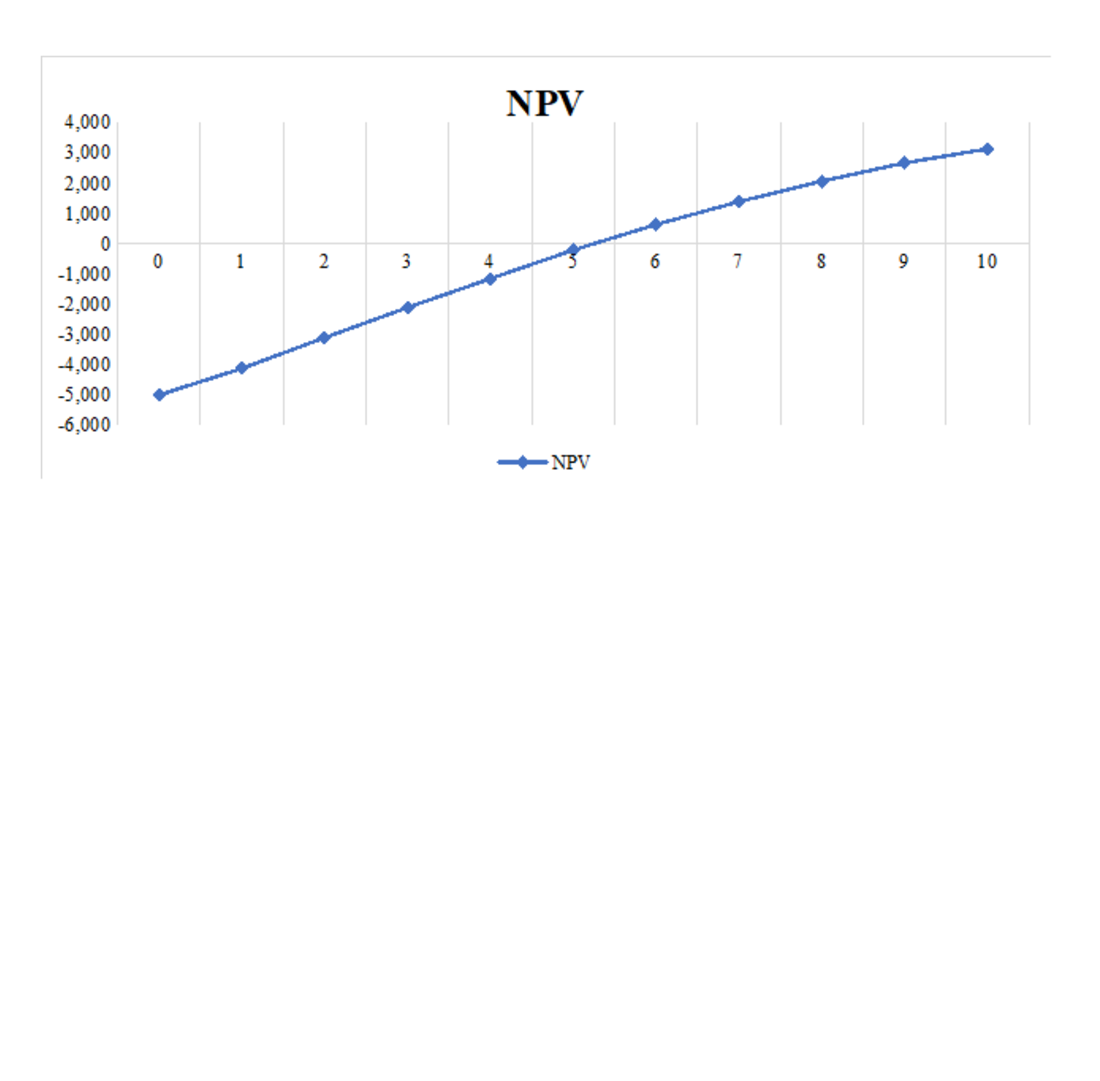

Проведений аналіз свідчить про високу фінансово-економічну ефективність запропонованого рішення. Середнє 10-річне співвідношення OIBDA до виручки становить 55,0 %, співвідношення чистого прибутку до виручки – 30 %, а внутрішньої норми прибутку – 23,79 %, що забезпечує високу стійкість проекту в умовах операційної діяльності та дозволяє його фінансування за рахунок виручки. Незважаючи на те, що проект потребує значних інвестицій, він характеризується відносно швидким терміном окупності: 5 років 8 місяців при середньозваженій вартості капіталу 15 %. Це свідчить про достатню інвестиційну привабливість проекту. Реалізація проекту скорочує викиди CO2 на 49 481 тони та відходів на 15 834 тони за 10 років, заощаджує енергію на 885 135 кВт/год, забезпечуючи пріоритети зеленої економіки.

Для аналізу економічної ефективності реалізації проекту використовувався метод дисконтованих грошових потоків.

Особливістю отриманих результатів є те, що для оцінки розроблено фінансову модель, перевагою якої є облік усіх основних грошових потоків проекту, що забезпечує інтереси підприємства.

Результати дослідження можуть бути використані при прийнятті управлінських рішень щодо раціоналізації використання сировини на підприємствах, а також державними органами за програмами зеленої економіки

Посилання

- Abildayeva, A., Turgumbayeva, K., Blumberga, D. (2021). Systematization of Material Flows of Natural and Secondary Raw Materials of Phosphorus Industry of the Republic of Kazakhstan. Environmental and Climate Technologies, 25 (1), 894–906. https://doi.org/10.2478/rtuect-2021-0067

- Schrijvers, D., Hool, A., Blengini, G. A., Chen, W.-Q., Dewulf, J., Eggert, R. et al. (2020). A review of methods and data to determine raw material criticality. Resources, Conservation and Recycling, 155, 104617. https://doi.org/10.1016/j.resconrec.2019.104617

- Mineral Resources Economics 2 (2021). Wiley. https://doi.org/10.1002/9781119882121

- Nursapina, K., Kuangaliyeva, T., Uryngaliyeva, A., Ibadildin, N., Serikbayev, S., Tulegenova, A., Kenzhin, Z. (2024). Mutual influence of energy efficiency and innovation activity in the industrial sector of the economy. Eastern-European Journal of Enterprise Technologies, 2 (13 (128)), 6–14. https://doi.org/10.15587/1729-4061.2024.299654

- Brunet, N. D., Longboat, S. (2023). Local Communities and the Mining Industry. Routledge. https://doi.org/10.4324/9781003182375

- Adams, R. G., Gilbert, C. L., Stobart, C. G. (2019). Modern Management in the Global Mining Industry. Emerald Publishing Limited. https://doi.org/10.1108/9781789737875

- Tazhibekova, K., Shametova, A., Urazbekov, A., Akhmetzhanov, B., Akenov, S., Tulupova, S. (2020). Enhancing eco-economic efficiency of mineral deposit exploration to achieve sustainable development in the mining industry of Kazakhstan. Progress in Industrial Ecology, An International Journal, 14 (3/4), 212. https://doi.org/10.1504/pie.2020.113425

- Henckens, T. (2021). Governance of the World’s Mineral Resources. Elsevier. https://doi.org/10.1016/c2020-0-01047-9

- Mineral Resources Economics 1 (2021). Wiley. https://doi.org/10.1002/9781119850861

- Benndorf, J. (2020). Closed Loop Management in Mineral Resource Extraction. In SpringerBriefs in Applied Sciences and Technology. Springer International Publishing. https://doi.org/10.1007/978-3-030-40900-5

- Hund, K., La Porta, D., Fabregas, T. P., Laing, T., Drexhage, J. (2023). Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition. The World Bank Group. https://doi.org/10.1596/40002

- Jhariya, M. K., Meena, R. S., Meena, S. N. (Eds.) (2022). Natural Resources Conservation and Advances for Sustainability. Elsevier. https://doi.org/10.1016/c2019-0-03763-6

- Purvis, B., Mao, Y., Robinson, D. (2018). Three pillars of sustainability: in search of conceptual origins. Sustainability Science, 14 (3), 681–695. https://doi.org/10.1007/s11625-018-0627-5

- Bashir, M. F., Shahbaz, M., Malik, M. N., Ma, B., Wang, J. (2023). Energy transition, natural resource consumption and environmental degradation: The role of geopolitical risk in sustainable development. Resources Policy, 85, 103985. https://doi.org/10.1016/j.resourpol.2023.103985

- Erdoğan, S., Çakar, N. D., Ulucak, R., Danish, Kassouri, Y. (2020). The role of natural resources abundance and dependence in achieving environmental sustainability: Evidence from resource‐based economies. Sustainable Development, 29 (1), 143–154. https://doi.org/10.1002/sd.2137

- Hammarstrom, J. M., Kreiner, D. C., Dicken, C. L., Woodruff, L. G. (2023). National map of focus areas for potential critical mineral resources in the United States. Fact Sheet. https://doi.org/10.3133/fs20233007

- Critical Raw materials resilience: charting a path towards greater security and sustainability (2020). European Commission. Available at: https://ec.europa.eu/docsroom/documents/42849

- Satapathy, S., Mishra, M., Das, M. R. (2024). Sustainable Waste Management Practices for the Mining Sector Through Recycling of Mining Waste. In SpringerBriefs in Earth System Sciences. Springer Nature Switzerland. https://doi.org/10.1007/978-3-031-67932-2

- Chauhan, G., Kaur, P. J., Pant, K. K., Nigam, K. D. P. (2020). Sustainable Metal Extraction from Waste Streams. Wiley. https://doi.org/10.1002/9783527826704

- Downs, T. J., Roa, A. C., Dixon, K. C., Duff, P., Pasay, E., Silverfine, H. (2020). The Case for Integrative Sustainable Development Practice Based on the Minas Conga Gold-Mining Experience in Peru. Journal of Geoscience and Environment Protection, 08 (05), 17–40. https://doi.org/10.4236/gep.2020.85002

- European Geological Data Infrastructure. EDGI. Available at: http://www.europe-geology.eu/

- Lèbre, É., Corder, G. D., Golev, A. (2017). Sustainable practices in the management of mining waste: A focus on the mineral resource. Minerals Engineering, 107, 34–42. https://doi.org/10.1016/j.mineng.2016.12.004

- Sonderegger, T., Berger, M., Alvarenga, R., Bach, V., Cimprich, A., Dewulf, J. et al. (2020). Mineral resources in life cycle impact assessment – part I: a critical review of existing methods. The International Journal of Life Cycle Assessment, 25 (4), 784–797. https://doi.org/10.1007/s11367-020-01736-6

- Zhao, Y., Gu, X., Qiu, J., Zhang, S., Guo, Z., Sun, X. (2022). Recycling of arsenic-containing biohydrometallurgy waste to produce a binder for cemented paste backfill: Co-treatment with oil shale residue. Journal of Environmental Management, 319, 115621. https://doi.org/10.1016/j.jenvman.2022.115621

- Wang, C., Xiong, D. (2021). Leaching assessment of aerated concrete made of recycled shale gas drilling cuttings: Particular pollutants, physical performance and environmental characterization. Journal of Cleaner Production, 282, 125099. https://doi.org/10.1016/j.jclepro.2020.125099

- Speight, J. (2020). Shale Oil and Gas Production Processes. Gulf Professional Publishing. https://doi.org/10.1016/c2015-0-02189-x

- Adamson, J., Irha, N., Adamson, K., Steinnes, E., Kirso, U. (2010). Effect of oil shale ash application on leaching behavior of arable soils: an experimental study. Oil Shale, 27 (3), 250. https://doi.org/10.3176/oil.2010.3.06

- Gavin, M. J., Perdew, W. E.., Hill, H. H. (1921). Notes on the oil-shale industry with particular reference to the Rocky Mountain district. Washington, D.C.: U.S. Dept. of the Interior, Bureau of Mines.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Tana Abylaikhanova, Zhadyra Kinasheva, Aliya Dossanova, Mainur Ordabayeva, Yerzhan Domalatov, Raikhan Mugauina, Assel Apysheva, Gulnafiz Bekbussinova

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.