Determining the loading of a container for grain transportation under operating conditions

DOI:

https://doi.org/10.15587/1729-4061.2025.325519Keywords:

railroad transport, container, container modernization, container load, container strength, container transportationAbstract

The object of this study is the processes of perception and redistribution of loads in the structure of a container for grain transportation under operating conditions. The task to address is to provide the railroad industry with vehicles for grain transportation by modernizing universal containers.

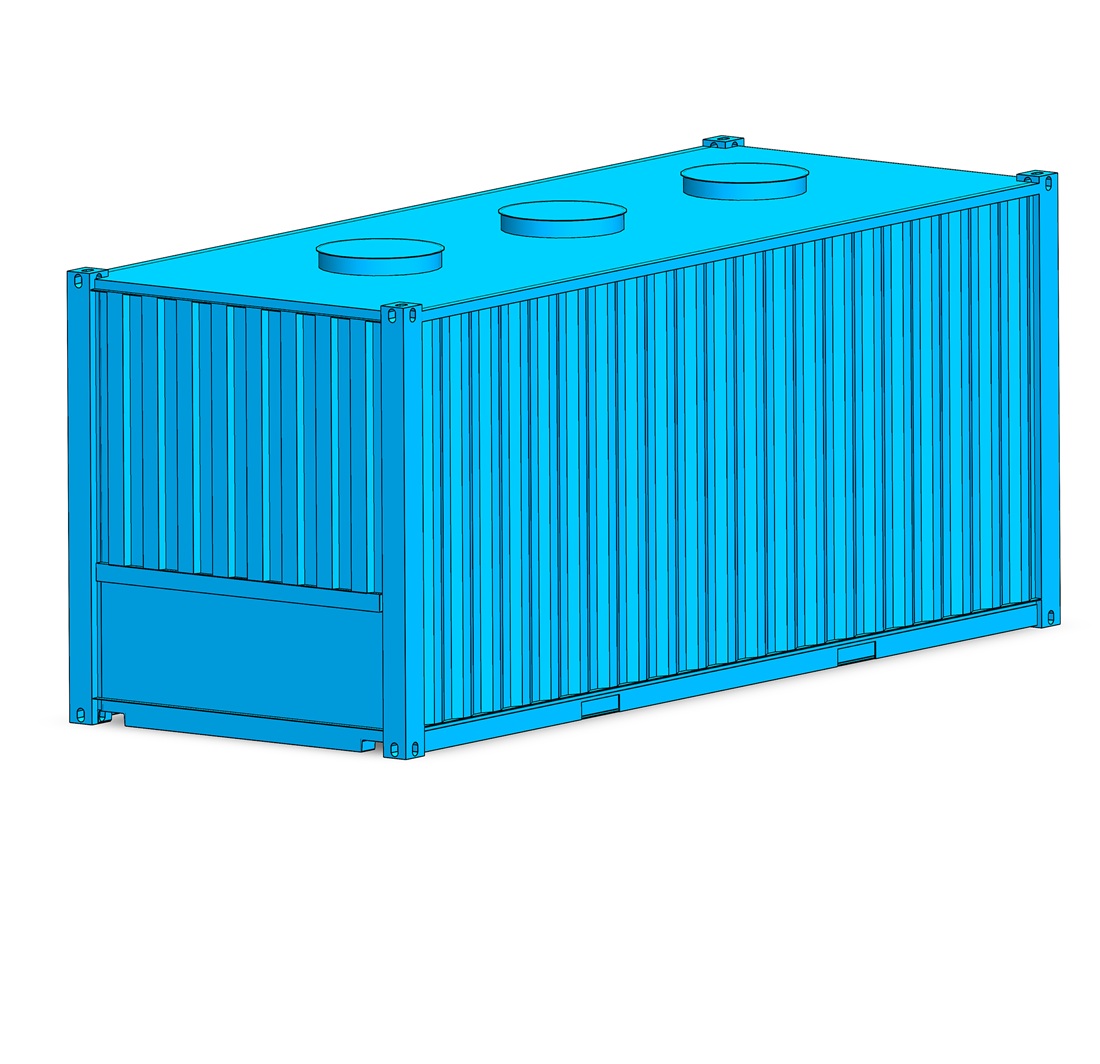

To upgrade the universal container for grain transportation, a 1CC container was selected as a prototype. In order to adapt this container for grain transportation, it is proposed to install three standard-diameter loading hatches on the roof. It is planned to make an unloading hatch in the end wall 1/3 of the height of the lower strapping. To substantiate the proposed solution, the strength of the container was calculated under the following loading scenarios: transporting the container as part of a railroad train; lifting by the upper corner fittings; unloading the container. The calculation results showed that the strength of the container is ensured under all the considered loading schemes.

A special feature of the results is that the provision of the railroad industry with vehicles for grain transportation is achieved not by designing new structures but by modernizing existing ones.

The field of practical application of the research results is railroad transport. The conditions for the practical use of the results are the application of low-alloy steel to fabricate the components of the container structure.

The results of the study will help compile recommendations for the modernization and design of container structures, as well as to improve the efficiency of container transportation, including international traffic

References

- Soukup, J., Skočilas, J., Skočilasová, B., Dižo, J. (2017). Vertical Vibration of Two Axle Railway Vehicle. Procedia Engineering, 177, 25–32. https://doi.org/10.1016/j.proeng.2017.02.178

- Dižo, J., Blatnický, M., Harušinec, J., Suchánek, A. (2022). Assessment of Dynamics of a Rail Vehicle in Terms of Running Properties While Moving on a Real Track Model. Symmetry, 14 (3), 536. https://doi.org/10.3390/sym14030536

- Gerlici, J., Lovska, A., Vatulia, G., Pavliuchenkov, M., Kravchenko, O., Solčanský, S. (2023). Situational Adaptation of the Open Wagon Body to Container Transportation. Applied Sciences, 13 (15), 8605. https://doi.org/10.3390/app13158605

- Lee, H.-A., Jung, S.-B., Jang, H.-H., Shin, D.-H., Lee, J. U., Kim, K. W., Park, G.-J. (2015). Structural-optimization-based design process for the body of a railway vehicle made from extruded aluminum panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230 (4), 1283–1296. https://doi.org/10.1177/0954409715593971

- Galimova, F., Khurmatov, Y., Abdulloev, M., Jumabekov, B., Sultonaliev, D., Ergeshova, D. (2021). Modern Gondola with Lightweight Body. XIV International Scientific Conference “INTERAGROMASH 2021,” 1043–1050. https://doi.org/10.1007/978-3-030-80946-1_94

- Vatulia, G. L., Lovska, A. O., Krasnokutskyi, Y. S. (2023). Research into the transverse loading of the container with sandwich-panel walls when transported by rail. IOP Conference Series: Earth and Environmental Science, 1254 (1), 012140. https://doi.org/10.1088/1755-1315/1254/1/012140

- Tiernan, S., Fahy, M. (2002). Dynamic FEA modelling of ISO tank containers. Journal of Materials Processing Technology, 124 (1-2), 126–132. https://doi.org/10.1016/s0924-0136(02)00196-6

- Rzeczycki, A., Wiśnicki, B. (2016). Strength Analysis of Shipping Container Floor with Gooseneck Tunnel under Heavy Cargo Load. Solid State Phenomena, 252, 81–90. https://doi.org/10.4028/www.scientific.net/ssp.252.81

- Yildiz, T. (2019). Design and Analysis of a Lightweight Composite Shipping Container Made of Carbon Fiber Laminates. Logistics, 3 (3), 18. https://doi.org/10.3390/logistics3030018

- Antala, D. K., Satasiya, R. M., Chauhan, P. M. (2020). Design, development and performance evaluation of transportation container for sapota fruit. Journal of Food Science and Technology, 58 (10), 4024–4033. https://doi.org/10.1007/s13197-020-04865-w

- Lovska, A., Stanovska, I., Kyryllova, V., Okorokov, A., Vernigora, R. (2024). Determining the vertical load on a container with a floor made of sandwich panels transported by a flat wagon. Eastern-European Journal of Enterprise Technologies, 6 (7 (132)), 36–44. https://doi.org/10.15587/1729-4061.2024.315059

- Rahimov, R. V., Khadjimukhametova, M. A., Rakhmatov, Z. X. (2016). Development of improved technical means for transportation fruits and vegetables. European Science Review, 1-2, 175–177. https://doi.org/10.20534/esr-16-1.2-175-177

- Poklemba, R., Zajac, J., Goldyniak, D., Olexa, I., Dilýová, M. (2020). Construction proposal of shipping bulk container. IOP Conference Series: Materials Science and Engineering, 776 (1), 012046. https://doi.org/10.1088/1757-899x/776/1/012046

- Siasiev, A. V. (2004). Vstup do systemy MathCad. Dnipropetrovsk, 108. Available at: https://mmf.dnu.dp.ua/wp-content/uploads/2020/01/mathcad_sayt.pdf

- Bohach, I. V., Krakovetskyi, O. Yu., Kylyk, L. V. (2020). Chyselni metody rozviazannia dyferentsialnykh rivnian zasobamy MathCad. Vinnytsia, 106. Available at: http://pdf.lib.vntu.edu.ua/books/IRVC/Bogach_2020_106.pdf

- Steišūnas, S., Dižo, J., Bureika, G., Žuraulis, V. (2017). Examination of Vertical Dynamics of Passenger Car with Wheel Flat Considering Suspension Parameters. Procedia Engineering, 187, 235–241. https://doi.org/10.1016/j.proeng.2017.04.370

- Gerlici, J., Lovska, A., Kozáková, K. (2025). Research into the Longitudinal Loading of an Improved Load-Bearing Structure of a Flat Car for Container Transportation. Designs, 9 (1), 12. https://doi.org/10.3390/designs9010012

- Dizo, J., Blatnicky, M. (2019). Evaluation of Vibrational Properties of a Three-wheeled Vehicle in Terms of Comfort. Manufacturing Technology, 19 (2), 197–203. https://doi.org/10.21062/ujep/269.2019/a/1213-2489/mt/19/2/197

- Zub, E., Tkachenko, V., Sapronova, S., Syvakivskiy, S. (2024). Determining the influence of wheelset arrangement in the model 18-100 bogies on the level of steering efforts in the wheel-rail flange contacts. Eastern-European Journal of Enterprise Technologies, 3 (7 (129)), 38–46. https://doi.org/10.15587/1729-4061.2024.304328

- Koziar, M. M., Feshchuk, Yu. V., Parfeniuk, O. V. (2018). Kompiuterna hrafika: SolidWorks. Kherson: Oldi-plius, 252. Available at: https://ep3.nuwm.edu.ua/22175/1/Комп%27ютерна%20графіка.pdf

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Rybin, A., Kravchenko, O. (2023). Strength Assessment of an Improved Design of a Tank Container under Operating Conditions. Communications - Scientific Letters of the University of Zilina, 25 (3), B186–B193. https://doi.org/10.26552/com.c.2023.047

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Ravlyuk, V., Harusinec, J. (2023). Studying the load of composite brake pads under high-temperature impact from the rolling surface of wheels. EUREKA: Physics and Engineering, 4, 155–167. https://doi.org/10.21303/2461-4262.2023.002994

- Mikhailov, E., Semenov, S., Dižo, J., Kravchenko, K. (2019). Research of possibilities of reducing the driving resistance of a railway vehicle by means of the wheel construction improvement. Transportation Research Procedia, 40, 831–838. https://doi.org/10.1016/j.trpro.2019.07.117

- Kondratiev, A. V., Kovalenko, V. O. (2019). Optimization of design parameters of the main composite fairing of the launch vehicle under simultaneous force and thermal loading. Space Science and Technology, 25 (4), 3–21. https://doi.org/10.15407/knit2019.04.003

- Koshel, O., Sapronova, S., Kara, S. (2023). Revealing patterns in the stressed-strained state of load-bearing structures in special rolling stock to further improve them. Eastern-European Journal of Enterprise Technologies, 4 (7 (124)), 30–42. https://doi.org/10.15587/1729-4061.2023.285894

- Gerlici, J., Lovska, A., Pavliuchenkov, M. (2024). Study of the Dynamics and Strength of the Detachable Module for Long Cargoes under Asymmetric Loading Diagrams. Applied Sciences, 14 (8), 3211. https://doi.org/10.3390/app14083211

- Vatulia, G., Lovska, A., Pavliuchenkov, M., Nerubatskyi, V., Okorokov, A., Hordiienko, D. et al. (2022). Determining patterns of vertical load on the prototype of a removable module for long-size cargoes. Eastern-European Journal of Enterprise Technologies, 6 (7 (120)), 21–29. https://doi.org/10.15587/1729-4061.2022.266855

- Liguori, A., Formato, A., Pellegrino, A., Villecco, F. (2021). Study of Tank Containers for Foodstuffs. Machines, 9 (2), 44. https://doi.org/10.3390/machines9020044

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Alyona Lovska, Nurlana Karimova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.