Identifying the influence of micro profile of rural roads on the durability of bus body when carrying passengers

DOI:

https://doi.org/10.15587/1729-4061.2025.325773Keywords:

bus body durability, simulation modeling, passenger, rural roads, road micro profileAbstract

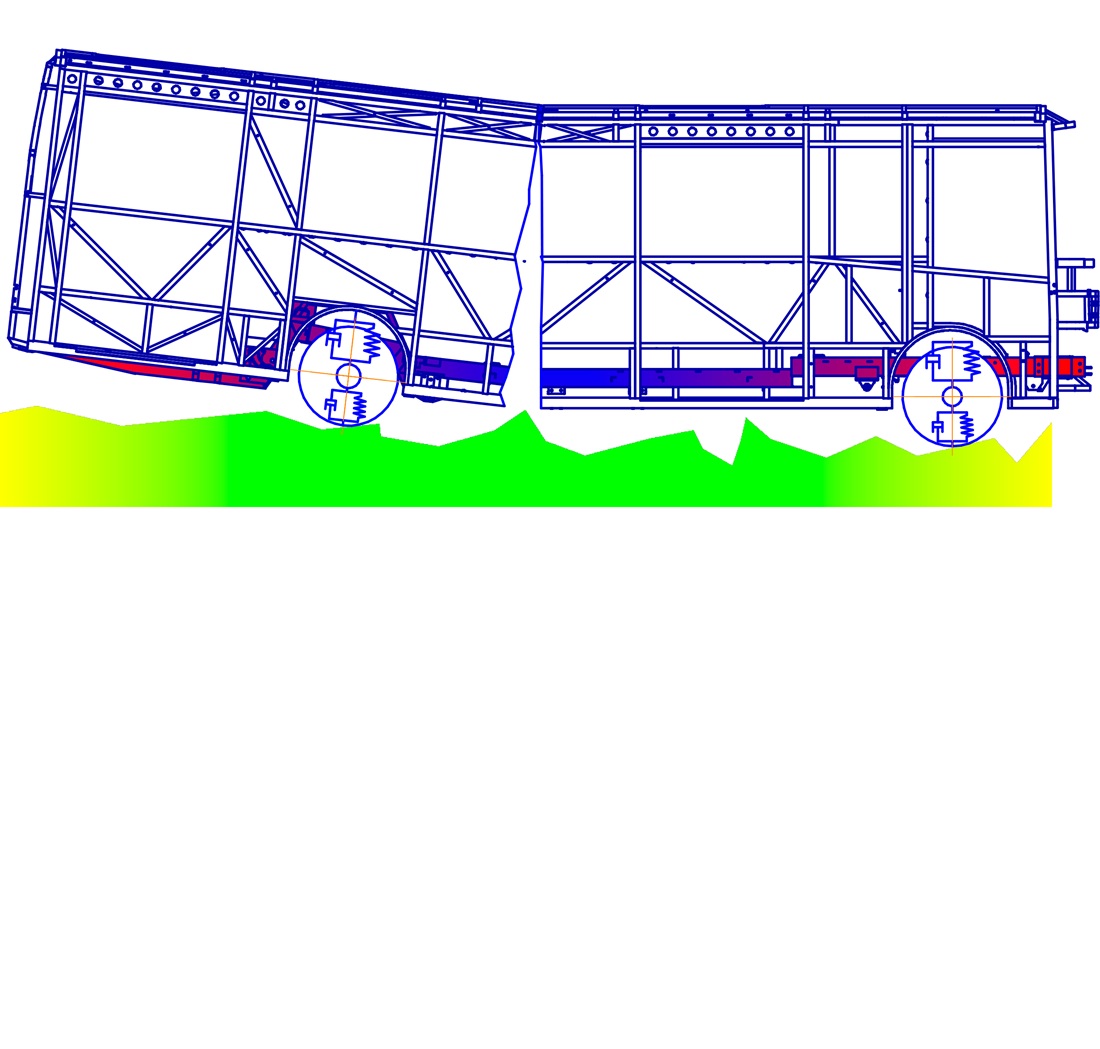

The object of this study is the durability of a bus body when passengers are transported on rural roads.

According to the European classification, the total length of roads in Ukraine that correspond to the first category does not exceed 5 %. That is, all other 95 % of roads have a quality level that does not meet the regulatory operating conditions. In particular, in rural areas, buses are operated both on worn asphalt-concrete surfaces and on dirt and gravel roads. Such operating conditions additionally lead to intensive wear of buses and significantly worsen the durability of their bodies. The task to determine the influence of worn and dirt roads on the durability of the bus body during passenger transportation in rural areas could be solved by the durability assessment procedure proposed in this paper.

The current work presents patterns that make it possible to predict the degradation of the bus body material that affect the durability of the body. The factors of influence during the operation of buses on rural routes have been substantiated and presented. The simulation results show that when operating buses on rural roads, cracks in the body frame of the body occur at runs that are 3.8–13.1 times less than under regulatory operating conditions.

The proposed procedure for assessing the durability of a bus body when transporting passengers on rural roads makes it possible to predict the deterioration of the physical and mechanical properties of the elements of the bus body frame and take measures at the design stage to increase their reliability and durability

References

- Regulation No 66 of the Economic Commission for Europe of the United Nations (UN/ECE) – Uniform provisions concerning the approval of large passenger vehicles with regard to the strength of their superstructure. Available at: https://eur-lex.europa.eu/eli/reg/2011/66(2)/oj

- Ruban, D., Kraynyk, L., Ruban, H., Hrubel, M., Duzhyi, R., Babaryha, A. (2022). Development of technological principles of technical control of bus bodies during operation based on passive safety conditions. Eastern-European Journal of Enterprise Technologies, 6 (1 (120)), 91–100. https://doi.org/10.15587/1729-4061.2022.268178

- Ruban, D., Kraynyk, L., Ruban, H., Sosyk, A., Shcherbyna, A., Dudarenko, O., Artyukh, A. (2021). Forecasting the durability of public transport bus bodies depending on operating conditions. Eastern-European Journal of Enterprise Technologies, 4 (1 (112)), 26–33. https://doi.org/10.15587/1729-4061.2021.238171

- Ruban, D., Kraynyk, L. (2017). Research of change of structure of material longerons to framework of basket of bus in the conditions of exploitation. Suchasni tekhnolohiyi v mashynobuduvanni ta transporti, 2 (9), 139–143. Available at: http://nbuv.gov.ua/UJRN/ctmbt_2017_2_23

- Ruban, D., Kraynyk, L. (2018). Methodology of predictive estimation of lifetime buses. Suchasni tekhnolohiyi v mashynobuduvanni ta transporti, 2 (11), 117–121. Available at: http://nbuv.gov.ua/UJRN/ctmbt_2018_2_22

- Mitschke, M., Wallentowitz, H. (2014). Dynamik der Kraftfahrzeuge. Springer-Verlag, 919. https://doi.org/10.1007/978-3-658-05068-9

- Farahani, B. V., Ramos, N. V., Moreira, P. M. G. P., Cunha, R., Costa, A., Maia, R., Rodrigues, R. M. (2022). Passive Safety Solutions on Transit Buses: Experimental and Numerical Analyses. Procedia Structural Integrity, 37, 668–675. https://doi.org/10.1016/j.prostr.2022.01.136

- Boutar, Y., Naïmi, S., Mezlini, S., Carbas, R. J. C., da Silva, L. F. M., Ben Sik Ali, M. (2021). Cyclic fatigue testing: Assessment of polyurethane adhesive joints’ durability for bus structures’ aluminium assembly. Journal of Advanced Joining Processes, 3, 100053. https://doi.org/10.1016/j.jajp.2021.100053

- Kepka, M., Kepka, M., Václavík, J., Chvojan, J. (2019). Fatigue life of a bus structure in normal operation and in accelerated testing on special tracks. Procedia Structural Integrity, 17, 44–50. https://doi.org/10.1016/j.prostr.2019.08.007

- Kepka, M., Kepka, M., Dzugan, J., Konopik, P. (2019). Practical notes for assessing the fatigue life of bodyworks of buses and trolleybuses. Procedia Structural Integrity, 19, 595–603. https://doi.org/10.1016/j.prostr.2019.12.064

- Kepka, M., Kepka, M. (2020). Accelerated fatigue testing on special tracks as new part of methodology for bus/trolleybus development. Engineering Failure Analysis, 118, 104786. https://doi.org/10.1016/j.engfailanal.2020.104786

- Sabadka, D., Molnar, V., Fedorko, G., Knezo, D. (2023). Research on failure resistance of vehicle’s skeletons. Engineering Failure Analysis, 144, 106950. https://doi.org/10.1016/j.engfailanal.2022.106950

- Dassault Systèmes. Matlab Corporation. Available at: https://www.matlab.com/

- Brovtsyn, Y. N. (2015). Modeling of surface microprofile of fields and roads. Sbornik nauchnyh trudov. IAEP, 86, 59–68.

- Ruban, D., Lanets, O., Kraynyk, L., Kovalyshyn, S., Ruban, H., Madleňák, R., Maciaszczyk, M. (2024). Predictive Assessment of Bus Body Life in the Matlab Simulink Software Environment. Communications - Scientific Letters of the University of Zilina, 26 (1), B22–B30. https://doi.org/10.26552/com.c.2024.003

- Ruban, D. P. (2020). Mathematical Model of Forecasting Durability of Bus Bodies and Checking it for Adequacy. Visnyk of Vinnytsia Politechnical Institute, 150 (3), 81–89. https://doi.org/10.31649/1997-9266-2020-150-3-81-89

- Troschenko, V. T., Sosnovskiy, L. A. (1987). Soprotivlenie ustalosti metallov i splavov. Ch. 1. Kyiv: Naukova dumka, 504.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dmytro Ruban, Lybomyr Krainyk, Hanna Ruban, Stepan Khimka, Oleg Sukach, Vladyslav Khotunov, Viktor Shevchuk, Ihor Dufanets, Оlexandr Artyukh

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.