Evaluation of a combined heat sink and clamping method to mitigate weld distortion in low carbon steel using GMAW

DOI:

https://doi.org/10.15587/1729-4061.2025.328730Keywords:

thermal conductors, acicular ferrite, deformation, material characteristics, metal inert gas weldingAbstract

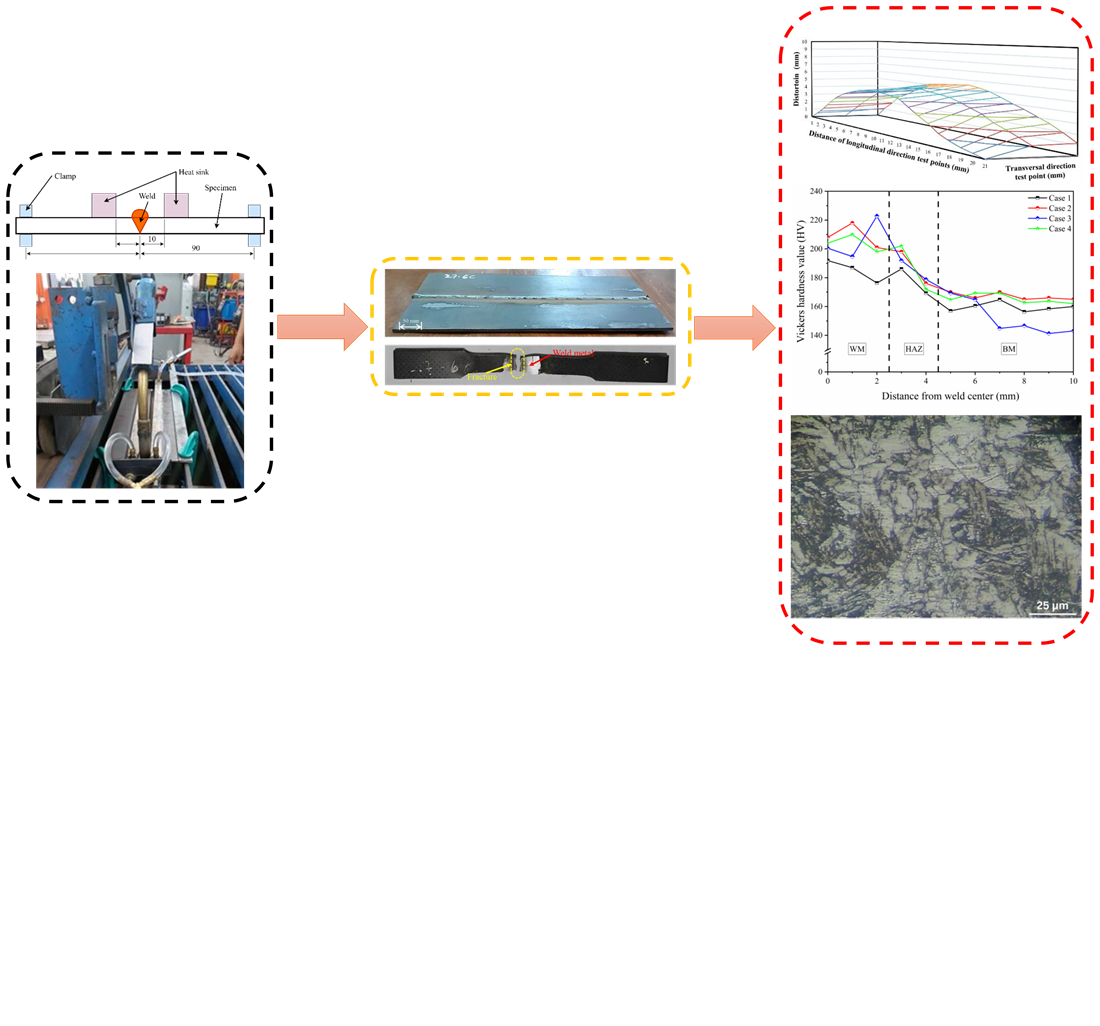

The mechanical strength and distortion management of GMAW-welded low-carbon steel (A36) joints are investigated in this work. GMAW is a combination of heat sinking and clamping procedures. Dimensional precision and structural reliability are compromised due to the substantial distortion caused during welding. To solve this problem, this research looks at a thermal-mechanical strategy that uses heat sinks and mechanical clamps in tandem when welding. Untreated joints (As-welded) and three different treatment variants (HS5-4C, HS27-4C, and HS27-6C) were tested in different experimental configurations. Using a 27 °C water-cooled heat sink and six steel clamps, the HS27-6C treatment significantly decreased longitudinal distortion, going from 6.7 mm (As-welded) to 0.85 mm, an astonishing 87% reduction. Mechanical testing showed that in all configurations, the tensile strength was approximately 500 MPa and that weld integrity was preserved since failures were in the base metal rather than the weld metal. Microstructural examination revealed an increase in Acicular Ferrite (AF) content in the weld metal for treated samples, particularly HS27-6C, which enhanced toughness, and microhardness tests verified consistent hardness values (e.g., weld metal (WM): ~200 HV, heat-affected zone (HAZ): ~170 HV, base metal (BM): ~150 HV). Mechanical restriction, in the form of clamps, reduces unequal expansion and contraction during solidification, and thermal management, accomplished by dispersing excess heat, is responsible for the method's efficacy. This integrated approach offers a realistic and cost-effective means of reducing distortion without sacrificing mechanical performance. This is particularly noteworthy in the structural, automotive, and manufacturing sectors, where precise control over dimensions is important

References

- Hajili, S. (2018). Welding processes for joining dissimilar metals and plastics. School of Industrial and Information Engineering, 1, 12–14.

- Ragavendran, M., Vasudevan, M., Hussain, N. (2022). Study of the Microstructure, Mechanical Properties, Residual Stresses, and Distortion in Type 316LN Stainless Steel Medium Thickness Plate Weld Joints. Journal of Materials Engineering and Performance, 31 (6), 5013–5025. https://doi.org/10.1007/s11665-021-06534-1

- Masubuchi, K. (1980). Analysis of welded structures: residual stresses, distortion, and their consequences. Elsevier. https://doi.org/10.1016/c2013-0-05818-5

- Oliveira, J. P., Santos, T. G., Miranda, R. M. (2020). Revisiting fundamental welding concepts to improve additive manufacturing: From theory to practice. Progress in Materials Science, 107, 100590. https://doi.org/10.1016/j.pmatsci.2019.100590

- Gray, T., Camilleri, D., McPherson, N. (2014). Control of welding distortion in thin-plate fabrication: design support exploiting computational simulation. Elsevier.

- Tabatabaeian, A., Ghasemi, A. R., Shokrieh, M. M., Marzbanrad, B., Baraheni, M., Fotouhi, M. (2021). Residual Stress in Engineering Materials: A Review. Advanced Engineering Materials, 24 (3). https://doi.org/10.1002/adem.202100786

- Li, Y., Zhao, Y., Li, Q., Wu, A., Zhu, R., Wang, G. (2017). Effects of welding condition on weld shape and distortion in electron beam welded Ti2AlNb alloy joints. Materials & Design, 114, 226–233. https://doi.org/10.1016/j.matdes.2016.11.083

- Singh, R. (2016). Applied welding engineering: processes, codes, and standards. Butterworth-Heinemann. https://doi.org/10.1016/c2015-0-00784-5

- Andritsos, F., Perez-Prat, J. (2000). State-of-the-art report on The Automation and Integration of Production Processes in Shipbuilding. European Commission, Joint Research Centre, ISIS. https://www.researchgate.net/publication/236095099

- Panji, M., Baskoro, A. S., Widyianto, A. (2019). Effect of Welding Current and Welding Speed on Weld Geometry and Distortion in TIG Welding of A36 Mild Steel Pipe with V-Groove Joint. IOP Conference Series: Materials Science and Engineering, 694 (1), 012026. https://doi.org/10.1088/1757-899x/694/1/012026

- Chen, B.-Q., Liu, K., Xu, S. (2024). Recent Advances in Aluminum Welding for Marine Structures. Journal of Marine Science and Engineering, 12 (9), 1539. https://doi.org/10.3390/jmse12091539

- Radaj, D. (1992). Heat effects of welding: temperature field, residual stress, distortion. Springer Science & Business Media, 348. https://doi.org/10.1007/978-3-642-48640-1

- Mohan, A., Franciosa, P., Dai, D., Ceglarek, D. (2024). A novel approach to control thermal induced buckling during laser welding of battery housing through a unilateral N-2-1 fixturing principle. Journal of Advanced Joining Processes, 10, 100256. https://doi.org/10.1016/j.jajp.2024.100256

- Ilman, M. N., Sehono, Muslih, M. R. (2022). Application of Hybrid Transient Thermal Tensioning/Trailing Active Cooling Treatment for Minimizing Distortion, Residual Stress, and Fatigue Crack Growth Rate of Friction Stir Welding Joints. Journal of Materials Engineering and Performance, 31 (9), 7772–7784. https://doi.org/10.1007/s11665-022-06788-3

- Liu, Z., Jin, X., Zhang, J., Hao, Z., Li, J., Chen, H. (2022). Numerical and experimental investigation on the mechanism of synchronous trailing cold air heat sink in eliminating the deformation during laser welding SUS301L thin sheet. Optics & Laser Technology, 153, 108258. https://doi.org/10.1016/j.optlastec.2022.108258

- Wibowo, H., Karyono, S., Prasetya, T. A., Nugroho, B. (2020). Non-destructive test inspection of gas metal arc welding products with clamp and heat sink treatment on low carbon steel. Journal of Physics: Conference Series, 1700 (1), 012003. https://doi.org/10.1088/1742-6596/1700/1/012003

- Δαούτης, Γ. Ν. (2023). Methods to control distortions of welded structures.

- Go, B.-S., Oh, K.-H., Kwon, S.-I., Bang, H.-S. (2022). Reduction Characteristics of Welding Deformation According to Cooling Distance in Heat Sink Welding. International Journal of Precision Engineering and Manufacturing, 23 (11), 1229–1236. https://doi.org/10.1007/s12541-022-00673-8

- Zhang, C., Li, S., Sun, J., Wang, Y., Deng, D. (2019). Controlling angular distortion in high strength low alloy steel thick-plate T-joints. Journal of Materials Processing Technology, 267, 257–267. https://doi.org/10.1016/j.jmatprotec.2018.12.023

- Gómora, C. M., Ambriz, R. R., Zuno-Silva, J., Jaramillo, D. (2020). Heat Sink Effect on 6061 Aluminum Alloy Welds with Different Partial Aging Conditions. Journal of Materials Engineering and Performance, 29 (7), 4339–4350. https://doi.org/10.1007/s11665-020-04982-9

- Jiang, K., Wang, C., Ren, J., Li, Z., Ma, T. (2025). Nondestructive inspection method of welding rate for heat sink fins with complex structure via infrared thermography principle and deep learning method. Expert Systems with Applications, 260, 125402. https://doi.org/10.1016/j.eswa.2024.125402

- Ramasamy, N., Jeyasimman, D., Kathiravan, R., Raju, N. (2019). Influence of Welding Sequence on Residual Stresses Induced in As-Welded Plug Weld of Low-Carbon Steel Plate. Transactions of the Indian Institute of Metals, 72 (5), 1361–1369. https://doi.org/10.1007/s12666-019-01631-1

- Yi, B., Fu, L., Xue, D., Liu, Y., Lei, W., Wang, J. (2024). Rapid analysis method for process parameter determination of transient thermal tensioning during welding buckling distortion mitigation. Thin-Walled Structures, 202, 112053. https://doi.org/10.1016/j.tws.2024.112053

- Zhao, H., Zhang, Q., Niu, Y., Du, S., Lu, J., Zhang, H., Wang, J. (2020). Influence of triangle reinforcement plate stiffeners on welding distortion mitigation of fillet welded structure for lightweight fabrication. Ocean Engineering, 213, 107650. https://doi.org/10.1016/j.oceaneng.2020.107650

- Sun, Y., Smith, M., Dutilleul, T., Jones, S. (2022). Assessing and mitigating the distortion and stress during electron beam welding of a large shell-flange structure. International Journal of Pressure Vessels and Piping, 199, 104772. https://doi.org/10.1016/j.ijpvp.2022.104772

- Barrios, A. M., Burgos, L. M., Niebles-Nuñez, E. E., Espitia, L. A., Unfried-Silgado, J. (2021). Influence of immersion corrosion on mechanical properties of AISI 430/AISI 316L dissimilar welded joints. International Journal of Engineering, 34 (5), 1352–1361. https://doi.org/10.5829/ije.2021.34.05b.31

- Widyianto, A., Baskoro, A. S., Kiswanto, G., Ganeswara, M. F. G. (2021). Effect of welding sequence and welding current on distortion, mechanical properties and metallurgical observations of orbital pipe welding on SS 316L. Eastern-European Journal of Enterprise Technologies, 2 (12 (110)), 22–31. https://doi.org/10.15587/1729-4061.2021.228161

- Wibowo, H., Surahmanto, F., Ilman, M. N. (2023). Identifying the influence of transient thermal tensioning treatments on minimizing distortion and improving fatigue behavior of steel welded. Eastern-European Journal of Enterprise Technologies, 4 (12 (124)), 37–46. https://doi.org/10.15587/1729-4061.2023.285192

- Holder, R., Larkin, N., Li, H., Kuzmikova, L., Pan, Z., Norrish, J. (2011). Development of a DC-LSND welding process for GMAW on DH-36 Steel. 56th WTIA annual conference 2011.

- Babu, P. D., Gouthaman, P., Marimuthu, P. (2019). Effect of Heat Sink and Cooling Mediums on Ferrite Austenite Ratio and Distortion in Laser Welding of Duplex Stainless Steel 2205. Chinese Journal of Mechanical Engineering, 32 (1). https://doi.org/10.1186/s10033-019-0363-5

- Babasafari, Z., Pan, A. V., Pahlevani, F., Hossain, R., Sahajwalla, V., du Toit, M., Dippenaar, R. (2020). Effects of austenizing temperature, cooling rate and isothermal temperature on overall phase transformation characteristics in high carbon steel. Journal of Materials Research and Technology, 9 (6), 15286–15297. https://doi.org/10.1016/j.jmrt.2020.10.071

- Long, S., Liang, Y., Jiang, Y., Liang, Y., Yang, M., Yi, Y. (2016). Effect of quenching temperature on martensite multi-level microstructures and properties of strength and toughness in 20CrNi2Mo steel. Materials Science and Engineering: A, 676, 38–47. https://doi.org/10.1016/j.msea.2016.08.065

- Lakshminarayanan, A. K., Balasubramanian, V. (2010). Tensile and Impact Toughness Properties of Gas Tungsten Arc Welded and Friction Stir Welded Interstitial Free Steel Joints. Journal of Materials Engineering and Performance, 20 (1), 82–89. https://doi.org/10.1007/s11665-010-9649-6

- Zhou, Q., Wang, Y., Choi, S.-K., Cao, L., Gao, Z. (2018). Robust optimization for reducing welding-induced angular distortion in fiber laser keyhole welding under process parameter uncertainty. Applied Thermal Engineering, 129, 893–906. https://doi.org/10.1016/j.applthermaleng.2017.10.081

- Jorge, L. de J., Cândido, V. S., Silva, A. C. R. da, Garcia Filho, F. da C., Pereira, A. C., Luz, F. S. da, Monteiro, S. N. (2018). Mechanical properties and microstructure of SMAW welded and thermically treated HSLA-80 steel. Journal of Materials Research and Technology, 7 (4), 598–605. https://doi.org/10.1016/j.jmrt.2018.08.007

- Abioye, T. E., Omotehinse, I. S., Oladele, I. O., Olugbade, T. O., Ogedengbe, T. I. (2020). Effects of post-weld heat treatments on the microstructure, mechanical and corrosion properties of gas metal arc welded 304 stainless steel. World Journal of Engineering, 17 (1), 87–96. https://doi.org/10.1108/wje-11-2019-0323

- Rizvi, S. A. (2020). Effect of Heat Input on Microstructural and Mechanical Properties of AISI 304 Welded Joint Via MIG Welding. International Journal of Engineering, 33 (9), 1811–1816. https://doi.org/10.5829/ije.2020.33.09c.16

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Heri Wibowo, Slamet Karyono, Tri Adi Prasetya, Ahmad Fikrie, Agus Widyianto

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.