Improving the technology of glued sausage casings from subgrade beef intestinal raw materials

DOI:

https://doi.org/10.15587/1729-4061.2025.328922Keywords:

glued sausage casings, pre-hydrolyzed acid treatment, local tanning, breaking loadAbstract

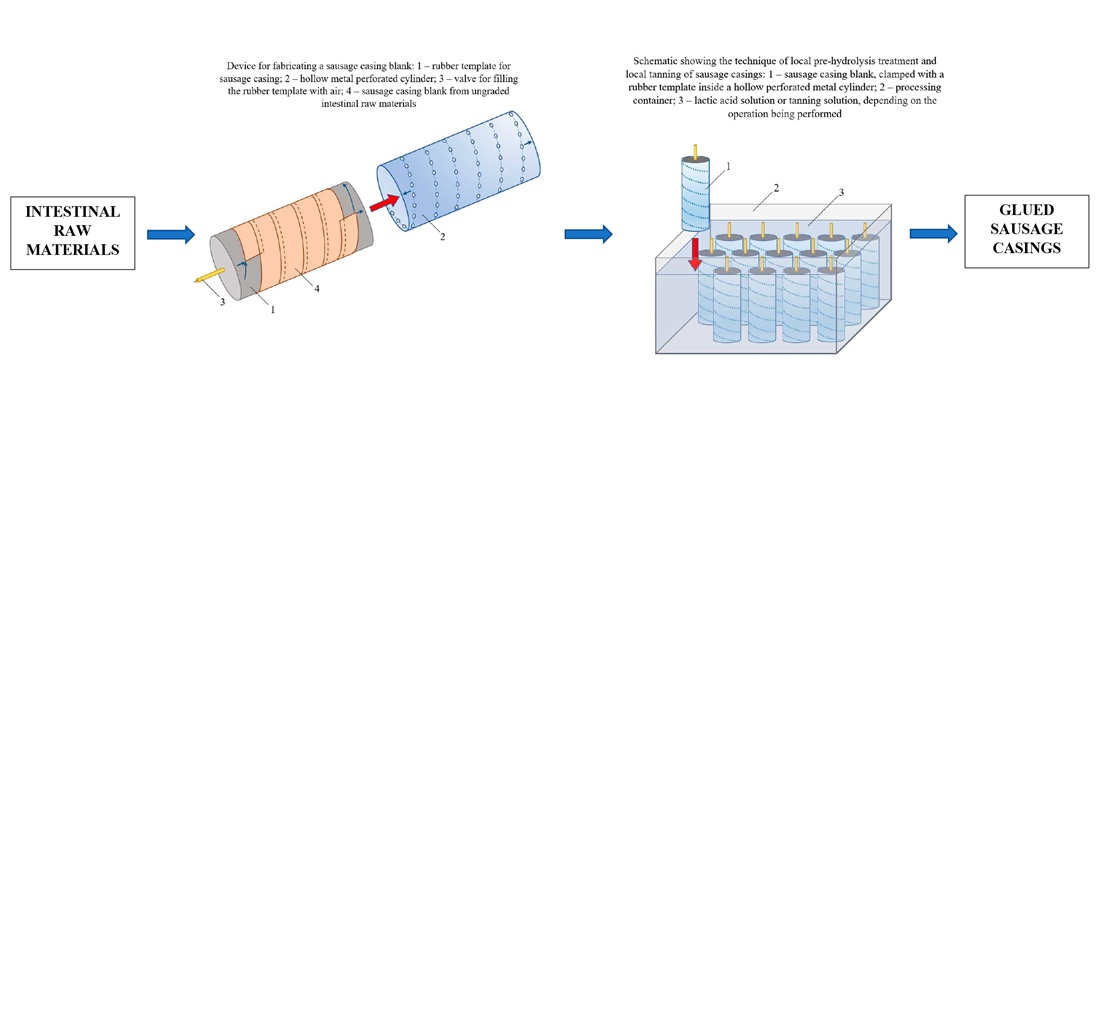

The object of this study is the technology of glued sausage casings from non-grade beef intestinal raw materials. Gluing is achieved through local tanning of the layers of intestinal raw materials to be glued. Tanning is used to give the gluing site irreversible properties, i.e., in the presence of such treatment, there is no delamination or separation of the gluing site. At the same time, due to the local tanning, the original properties of the raw material are preserved, namely, plasticity and elasticity. To accelerate the tanning process, the technique devised proposes using a preliminary local pre-hydrolytic acid treatment of the layers of raw materials to be glued. Local pre-hydrolytic acid treatment helps accelerate the diffusion process between the layers of intestinal casings to be glued and also helps reduce the duration of the operation of local tanning of the gluing sites treated in this way.

The rational parameters for local tanning have been determined, namely, the concentration of the tanning solution and the duration of local tanning provided that the raw material has been pre-hydrolyzed: the rational duration of local tanning is 10 hours at a tannin concentration in the tanning solution of 1.3%, at a tannin concentration of 2.0% – 5...5.5 hours. It has been established that there are certain pairs of values of these factors at which the seam strength (seam breaking load) is not less than the limit value of the seam breaking load, which is a necessary functional and technological condition for glued sausage casings. It has been established that the preliminary local pre-hydrolyzed acid treatment helps reduce the local tanning process by more than two times

References

- Alibekov, R. S., Alibekova, Z. I., Bakhtybekova, A. R., Taip, F. S., Urazbayeva, K. A., Kobzhasarova, Z. I. (2024). Review of the slaughter wastes and the meat by-products recycling opportunities. Frontiers in Sustainable Food Systems, 8. https://doi.org/10.3389/fsufs.2024.1410640

- Ciccullo, F., Cagliano, R., Bartezzaghi, G., Perego, A. (2021). Implementing the circular economy paradigm in the agri-food supply chain: The role of food waste prevention technologies. Resources, Conservation and Recycling, 164, 105114. https://doi.org/10.1016/j.resconrec.2020.105114

- Cusiatado Palomino, A. M., Farfán Carhuamaca., N. Y., Rada Mota, L. C. (2024). Systematic Review on Lean Manufacturing in the Productivity of the Food Industry. Proceedings of the 4th LACCEI International Multiconference on Entrepreneurship, Innovation and Regional Development (LEIRD 2024): “Creating Solutions for a Sustainable Future: Technology-Based Entrepreneurship.” https://doi.org/10.18687/leird2024.1.1.325

- Simonova, I., Drachuk, U., Halukh, B., Basarab, I., Koval, H., Nutskovskyi, Y. (2024). Innovative approaches to improving the barrier properties of natural sausage casings. Scientific Messenger of LNU of Veterinary Medicine and Biotechnologies, 26 (102), 21–29. https://doi.org/10.32718/nvlvet-f10204

- Knipe, C. L. (2024). Sausage casings. Encyclopedia of Meat Sciences, 440–445. https://doi.org/10.1016/b978-0-323-85125-1.00211-8

- Pak, A., Оnishchenko, V., Yancheva, М., Оnyshchenko, А., Grynchenko, N., Pak, А., Inzhyyants, S. (2024). Formation of functional and technological properties of the film from intestinal raw materials during the drying process. Food Science and Technology, 18 (1). https://doi.org/10.15673/fst.v18i1.2850

- Bartel, S., Holek, M., Domin, J., Karczewski, J., Kozielski, L., Pilch, Z., Wyciślok, A. (2020). Joining methods of natural sausage casing with using of high frequency current. Engineering Mechanics 2020, 26, 70–73. https://doi.org/10.21495/5896-3-070

- Bartel, S., Domin, J., Karczewski, J., Kciuk, M., Kozielski, L., Pilch, Z., Wyciślok, P. (2020). Testing the strength of laser-bonded animal intestines. Engineering Mechanics 2020, 26, 66–69. https://doi.org/10.21495/5896-3-066

- Оnishchenko, V., Pak, A., Goralchuk, A., Shubina, L., Bolshakova, V., Inzhyyants, S. et al. (2021). Devising techniques for reinforcing glued sausage casings by using different physical methods. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 6–13. https://doi.org/10.15587/1729-4061.2021.224981

- Wijnker, J. J. (2009). Aspects of quality assurance in processing natural sausage casings. Utrecht University. Available at: https://research-portal.uu.nl/en/publications/aspects-of-quality-assurance-in-processing-natural-sausage-casing

- Liu, W., Chen, X., Tsutsuura, S., Nishiumi, T. (2022). Toughness Variations among Natural Casings: An Exploration on Their Biochemical and Histological Characteristics. Foods, 11 (23), 3815. https://doi.org/10.3390/foods11233815

- Liu, F., Yu, Z., Wang, B., Chiou, B.-S. (2023). Changes in Structures and Properties of Collagen Fibers during Collagen Casing Film Manufacturing. Foods, 12 (9), 1847. https://doi.org/10.3390/foods12091847

- Pak, A., Оnishchenko, V., Yancheva, M., Grynchenko, N., Pak, A., Inzhyyants, S., Оnyshchenko, А. (2024). Devising a technology for obtaining glued sausage casings from intestinal raw materials using electrophoresis. Technology and Equipment of Food Production, 4 (11 (130)), 67–75. https://doi.org/10.15587/1729-4061.2024.308603

- Li, J., Li, S., Fang, J., Zhao, Q., Li, Y., Xia, T., Yang, C. (2023). Effect of silane surface modification on the bonding properties of the hot-pressing molded polycarbonate/aluminum alloy hybrid. Journal of Adhesion Science and Technology, 38 (8), 1191–1210. https://doi.org/10.1080/01694243.2023.2251768

- Li, D., Sheng, J., Zhuang, B., Wu, Z., Aladejana, J. T., Liu, J. (2019). Study on hot-pressing technology of chitosan-modified starch adhesive film. BioResources, 14 (2), 4316–4328. https://doi.org/10.15376/biores.14.2.4316-4328

- Onishchenko, V., Maryna, Y., Onyshchenko, A., Inzhyyants, S. (2024). Prehydrolysis changes of beef rounds water absorption under the acid treatment effect. Bulletin of the National Technical University «KhPI» Series: New Solutions in Modern Technologies, 1 (19), 65–69. https://doi.org/10.20998/2413-4295.2024.01.09

- Pak, A., Оnishchenko, V., Yancheva, M., Grynchenko, N., Dromenko, O., Pak, A. et al. (2023). Devising a technique and designing an apparatus for obtaining a multifunctional purpose film from intestinal raw materials. Eastern-European Journal of Enterprise Technologies, 3 (11 (123)), 6–15. https://doi.org/10.15587/1729-4061.2023.279008

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Andrey Pak, Vyacheslav Оnishchenko, Maryna Yancheva, Nataliya Grynchenko, Alina Pak, Samvel Inzhyyants, Аrtem Оnyshchenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.