Devising a technology for hot thermostable sauces based on dairy raw materials

DOI:

https://doi.org/10.15587/1729-4061.2025.330249Keywords:

hot sauces, thermal stability, emulsion structure, thermogravimetric indicators, rheological indicators, storageAbstract

The object of this study is the production of hot thermostable sauces based on dairy raw materials, as well as their thermogravimetric and rheological indicators, and changes during storage.

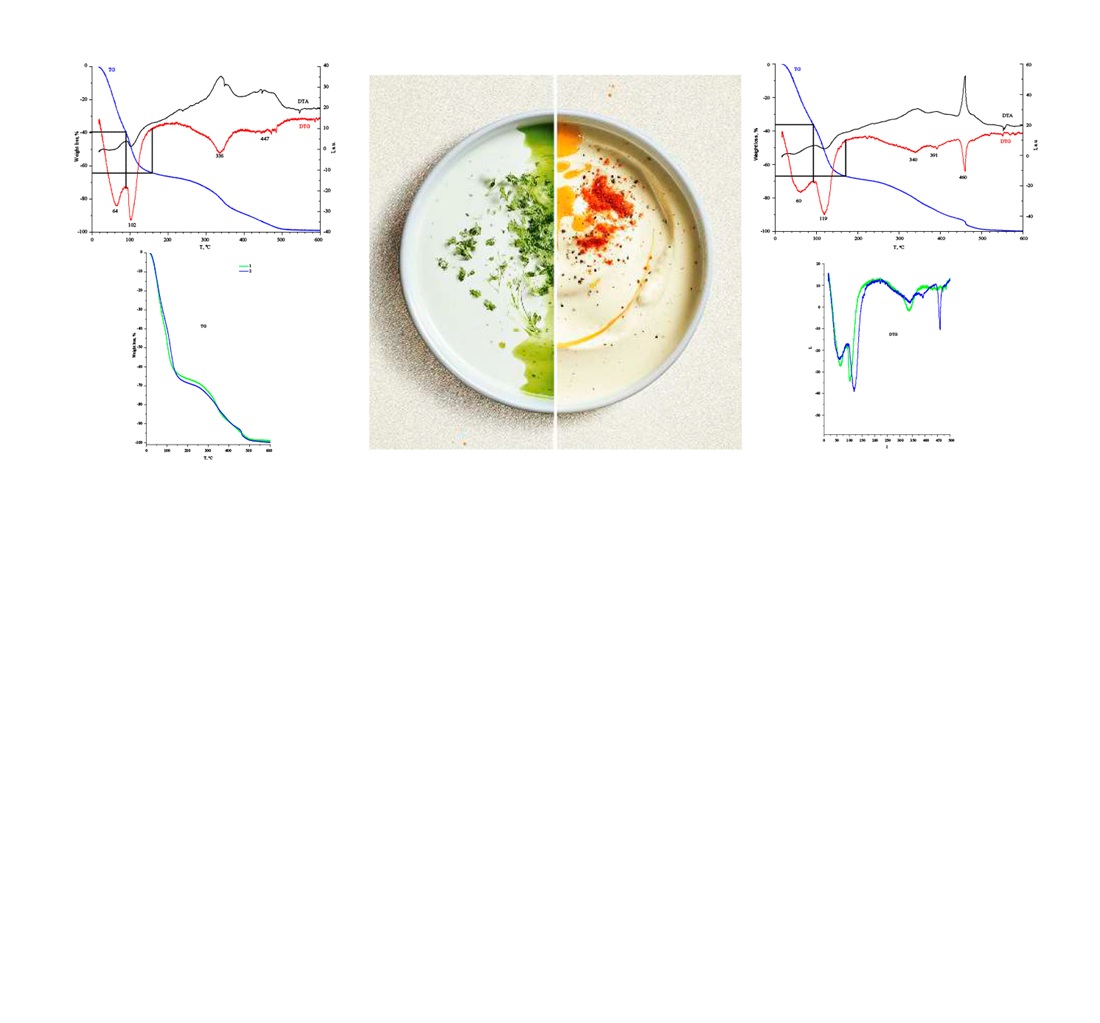

The principal task addressed in the study is to devise industrial technology for hot thermostable sauces, which requires ensuring the stability of their structure at all stages of the technological process. The devised sauce technology involves the formation of an emulsion structure and its stabilization by introducing modified waxy corn starch and xanthan gum with subsequent pasteurization of the sauce at temperatures of 87–90°C. Comparative analysis of SEM photographs of starch before and after heat treatment confirms its thermal stability, which is manifested in the integrity of starch grains and an undamaged shell. All sauce components are integrated into a single matrix, which contributes to the stability of the final product.

The thermogravimetric and rheological indicators of the sauce and their changes during storage were investigated. During storage, there is a redistribution of the amount of free and bound water: from 39% to 36% and from 26% to 29%; the viscosity of the sauce and the shear stress increase accordingly. Sauces are structured food systems, demonstrating typical non-Newtonian behavior. The approximation of the curves of storage modulus (G') and loss modulus (G'') at high values of angular frequency indicates the presence of cross-linked polymers.

A distinctive feature of the experimental results is that the determined thermogravimetric and rheological indicators are the basis for substantiating the shelf life of sauces. Devising a new technology could make it possible to expand the range of existing sauces and enable their industrial production. It is also the basis for the further development of the ready-to-eat segment, where sauces are a component of meals

References

- Xu, Y. (2024). Analysis of the development of prospect of premade food. SHS Web of Conferences, 207, 01030. https://doi.org/10.1051/shsconf/202420701030

- Sauces and Condiments Market – By Product Type, Form, Distribution Channel, Share, Growth Forecast, 2025-2034 (2025). Global market insights. Available at: https://www.gminsights.com/industry-analysis/sauces-and-condiments-market

- Szafrańska, J. O., Sołowiej, B. G. (2020). Cheese sauces: Characteristics of ingredients, manufacturing methods, microbiological and sensory aspects. Journal of Food Process Engineering, 43 (4). https://doi.org/10.1111/jfpe.13364

- Jimenez, P. S., Punia Bangar, S., Whiteside, W. S. (2024). Effects of different types of starches on heat penetration and physicochemical characteristics in alfredo sauce. Journal of Food Measurement and Characterization, 18 (10), 8888–8897. https://doi.org/10.1007/s11694-024-02853-8

- Sikora, M., Kowalski, S., Tomasik, P., Sady, M. (2007). Rheological and sensory properties of dessert sauces thickened by starch–xanthan gum combinations. Journal of Food Engineering, 79 (4), 1144–1151. https://doi.org/10.1016/j.jfoodeng.2006.04.003

- Ciprovica, I., Raits, E., Kirse-Ozolina, A. (2019). Designing of thermal treatment parameters for tomato sauces. Engineering for Rural Development. https://doi.org/10.22616/erdev2019.18.n119

- Asase, R. V., Glukhareva, T. V. (2023). Production and application of xanthan gum – prospects in the dairy and plant-based milk food industry: a review. Food Science and Biotechnology, 33 (4), 749–767. https://doi.org/10.1007/s10068-023-01442-7

- EL-mahdi, L., Saad, S., Hassan, Z., Awad, R. (2014). Starch and other stabilizers combinations asthickening agents in processed cheese sauces manufacture. Journal of Food and Dairy Sciences, 5 (11), 827–840. https://doi.org/10.21608/jfds.2014.53237

- Hassan, Z. M. R., Awad, R. A., Laila, D., Suhila A. EL-Mahdi, S. (2015) The use of food stabilizers in manufacture of cheese sauces. Biol. Chem. Environ. Sci., 9 (1), 357–372. Available at: https://www.researchgate.net/publication/319913908_THE_USE_OF_FOOD_STABILIZERS_IN_MANUFACTURE_OF_CHEESE_SAUCES

- Steeneken, P. A. M., Woortman, A. J. J., (Lizette) Oudhuis, A. A. C. M. (2011). Processing stability of cross-linked starches in acid sauce applications and identification of some of the molecular factors involved. Food Hydrocolloids, 25 (3), 410–418. https://doi.org/10.1016/j.foodhyd.2010.07.009

- Ianushkevych, O., Grynchenko, N., Radchenko, A., Smetanska, I., Marynin, A., Hrynchenko, O. (2025). Determining the influence of technological factors on the microstructural and rheological parameters of sauces with emulsion structure. Eastern-European Journal of Enterprise Technologies, 2 (11 (134)), 33–41. https://doi.org/10.15587/1729-4061.2025.325417

- Hrynchenko, O., Radchenko, A., Dehtiar, V., Grynchenko, N., Serik, M. (2025). Development of technology for food products with emulsion structure based on pea groats and pea aquafaba. Eastern-European Journal of Enterprise Technologies, 1 (11 (133)), 17–27. https://doi.org/10.15587/1729-4061.2025.323339

- Ianushkevich, O. I. (2023). Section 14. Analysis Of Technologies For Hot Sauces As The Basis For The Development Of An Innovative Idea Of New Products. Sustainable Food Chain And Safety Through Science, Knowledge And Business, 329–342. https://doi.org/10.30525/978-9934-26-328-6-14

- Alvarez, M., Fuentes, R., Canet, W. (2015). Effects of Pressure, Temperature, Treatment Time, and Storage on Rheological, Textural, and Structural Properties of Heat-Induced Chickpea Gels. Foods, 4 (2), 80–114. https://doi.org/10.3390/foods4020080

- Sudheesh, C., Sunooj, K. V., Sinha, S. K., George, J., Kumar, S., Murugesan, P. et al. (2019). Impact of energetic neutral nitrogen atoms created by glow discharge air plasma on the physico-chemical and rheological properties of kithul starch. Food Chemistry, 294, 194–202. https://doi.org/10.1016/j.foodchem.2019.05.067

- Guimarães, C. F., Gasperini, L., Ribeiro, R. S., Carvalho, A. F., Marques, A. P., Reis, R. L. (2020). High-throughput fabrication of cell-laden 3D biomaterial gradients. Materials Horizons, 7 (9), 2414–2421. https://doi.org/10.1039/d0mh00818d

- Mezger, T. G. (2019). The Rheology Handbook. Coatings. https://doi.org/10.1515/9783748600367

- Yanushkevich, O. I. (2022). Research of indicators of quality and safety of sauces thermostable based on dairy raw materials. Innovative Technologies And Equipment: Development Prospects Of The Food And Restaurant Industries, 350–364. https://doi.org/10.30525/978-9934-26-205-0-14

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Oleksandr Ianushkevych, Nataliya Grynchenko, Anna Radchenko, Andrii Marynin, Olha Hrynchenko, Maryna Kolesnikova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.