Обгрунтування критеріїв для оцінювання якості заморожених плодів черешні методом багатокритеріальної оптимізації

DOI:

https://doi.org/10.15587/1729-4061.2025.331599Ключові слова:

біохімічні показники, сенсорні параметри, геометрична згортка критеріїв, ранжування сортів, безвідходний ланцюгАнотація

Об’єктом дослідження є процес збереження біохімічних і сенсорних параметрів якості заморожених напівфабрикатів черешні.

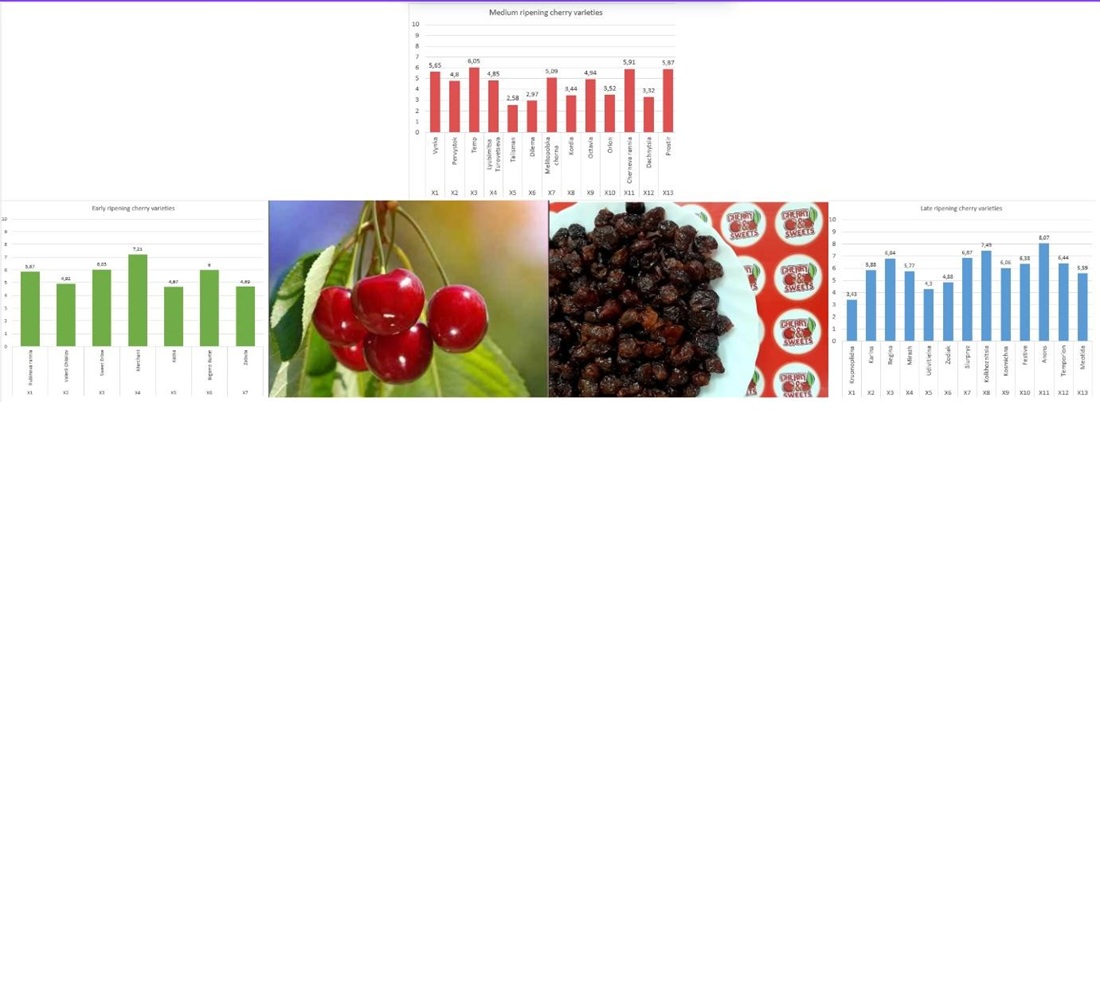

Сучасна харчова промисловість потребує стабільної якості продукції, розширення асортименту та збереження харчової цінності сировини з урахуванням сезонності. Важливу роль у цьому відіграє заморожена плодова сировина. Однак її якість часто є непередбачуваною, що ускладнює забезпечення стабільних технологічних характеристик кінцевого продукту. У цьому контексті особливої актуальності набуває наукове обґрунтування критеріїв оцінки якості заморожених плодів черешні. У дослідженні використано плоди 33 сортів черешні різних строків достигання. Здійснено аналіз статистичної оцінки свіжозаморожених плодів сортів черешні за комплексом параметрів та значеннями цільової функції.

За використання методу багатокритеріальної оптимізації було визначено найбільш придатні для заморожування сорти черешні. Найкращим сортом черешні раннього строку достигання визначено Казка (1 ранг) − j(х5)=4,67. Оптимальними для заморожування виділено плоди черешні середнього строку достигання сорту Талісман (1 ранг) − j(х₅)=3,58. За значеннями цільових функцій найкращими для заморожування рекомендовано сорт черешні пізнього строку достигання Крупноплідна (1 ранг) − j(х1)=3,43. На підставі проведених досліджень розроблено біохімічні та сенсорні критерії оцінки якості заморожених напівфабрикатів сортів черешні раннього, середнього та пізнього строків достигання для їх подальшого використання у виробництві. Отримані результати можуть бути використані для удосконалення критеріїв оцінки якості замороженої плодової сировини у межах безвідходного ланцюга постачання фруктів, що забезпечує ефективність та стале використання ресурсів для усіх зацікавлених сторін

Посилання

- Priss, O., Pugachov, M., Pugachov, V., Yaremko, I., Shchabelska, V. (2023). The Development of the World Economy and the Impact of the Global Food Crisis 2022-2023. Economic Affairs, 68 (1s). https://doi.org/10.46852/0424-2513.1s.2023.5

- Krasnova, I., Seglina, D., Pole, V. (2018). The effect of pre-treatment methods on the quality of dehydrated candied Japanese quince fruits during storage. Journal of Food Science and Technology, 55 (11), 4468–4476. https://doi.org/10.1007/s13197-018-3375-8

- Ivanova, I., Tymoshchuk, T., Kravchuk, M., Ishchenko, I., Kryvenko, A. (2023). Sensory evaluation of sweet cherries for sustainable fruit production in the European market. Scientific Horizons, 26 (10), 93–106. https://doi.org/10.48077/scihor10.2023.93

- Blando, F., Oomah, B. D. (2019). Sweet and sour cherries: Origin, distribution, nutritional composition and health benefits. Trends in Food Science & Technology, 86, 517–529. https://doi.org/10.1016/j.tifs.2019.02.052

- Magri, A., Malorni, L., Cozzolino, R., Adiletta, G., Siano, F., Picariello, G. et al. (2023). Agronomic, Physicochemical, Aromatic and Sensory Characterization of Four Sweet Cherry Accessions of the Campania Region. Plants, 12 (3), 610. https://doi.org/10.3390/plants12030610

- González-Gómez, D., Bernalte, M. J., Ayuso, M. C., Fernández-León, M. F., Lozano, M., Rato, A. E. et al. (2017). Evaluation of different postharvest conditions to preserve the amount of bioactive compounds, physicochemical quality parameters and sensory attributes of ‘Sweetheart’ cherries. Acta Horticulturae, 1161, 581–586. https://doi.org/10.17660/actahortic.2017.1161.92

- Ivanova, I., Serdyuk, M., Kryvonos, I., Yeremenko, O., Тymoshchuk, Т. (2020). Formation of flavoring qualities of sweet cherry fruits under the influence of weather factors. Scientific Horizons, 89 (4), 72–81. https://doi.org/10.33249/2663-2144-2020-89-4-72-81

- Ivanova, I., Serdyuk, M., Tymoshchuk, T., Malkina, V., Zinovieva, O., Lisohurska, D. et al. (2024). Minimizing sweet cherry fruit losses during storage under the influence of hydrocooling and protective organic composition. Eastern-European Journal of Enterprise Technologies, 4 (11 (130)), 16–25. https://doi.org/10.15587/1729-4061.2024.309595

- Ivanova, I., Serdyuk, M., Tymoshchuk, T., Malkina, V., Shkinder-Barmina, A., Drobitko, A. et al. (2024). Prediction of cherry fruit technological characteristics by RIDGE-regression method. Future of Food: Journal on Food, Agriculture & Society, 12 (1), 39–50. Available at: https://thefutureoffoodjournal.com/manuscript/index.php/FOFJ/article/view/691

- Huang, H., Ni, Z., Xie, J., Li, Y., Wen, H., Huang, Z. et al. (2024). Good Feasibility of Ozone-Microwave Treatment as a Sterilization Technology to Extend the Edible Life of Candied Fruit as a Post-processed Fresh Fruit Product. Food and Bioprocess Technology, 17 (10), 3086–3100. https://doi.org/10.1007/s11947-023-03315-7

- Huzova, I. (2020). Investigation of the Energy-Saving Method during Candied Fruits Filtration Drying. Periodica Polytechnica Chemical Engineering, 64 (4), 555–561. https://doi.org/10.3311/ppch.15107

- Ursache, F. M., Andronoiu, D. G., Ghinea, I. O., Barbu, V., Ioniţă, E., Cotârleţ, M. et al. (2018). Valorizations of carotenoids from sea buckthorn extract by microencapsulation and formulation of value-added food products. Journal of Food Engineering, 219, 16–24. https://doi.org/10.1016/j.jfoodeng.2017.09.015

- Ivanova, І., Serdyuk, М., Malkina, V., Tymoshchuk, T., Vorovka, M., Mrynskyi, I., Adamovych, A. (2022). Studies of the impact of environmental conditions and varietal features of sweet cherry on the accumulation of vitamin C in fruits by using the regression analysis method. Acta Agriculturae Slovenica, 118 (2). https://doi.org/10.14720/aas.2022.118.2.2404

- Mari, A., Parisouli, D. N., Krokida, M. (2024). Exploring Osmotic Dehydration for Food Preservation: Methods, Modelling, and Modern Applications. Foods, 13 (17), 2783. https://doi.org/10.3390/foods13172783

- Pandiselvam, R., Tak, Y., Olum, E., Sujayasree, O. J., Tekgül, Y., Çalışkan Koç, G. et al. (2021). Advanced osmotic dehydration techniques combined with emerging drying methods for sustainable food production: Impact on bioactive components, texture, color, and sensory properties of food. Journal of Texture Studies, 53 (6), 737–762. https://doi.org/10.1111/jtxs.12643

- Ivanova, I., Serdyuk, M., Malkina, V., Tymoshchuk, T., Kotelnytska, A., Moisiienko, V. (2021). The forecasting of polyphenolic substances in sweet cherry fruits under the impact of weather factors. Agraarteadus, 32(2), 239–250. https://doi.org/10.15159/jas.21.27

- Vasylyshina, O., Postolenko, Ye. (2019). Influence of variety characteristics on the quality of frozen cherry fruit. Scientific Horizons, 75 (2), 44–49. https://doi.org/10.33249/2663-2144-2019-75-2-44-49

- Aulin, V., Rogovskii, I., Lyashuk, O., Titova, L., Hrynkiv, A., Mironov, D. et al. (2024). Comprehensive assessment of technical condition of vehicles during operation based on Harrington’s desirability function. Eastern-European Journal of Enterprise Technologies, 1 (3 (127)), 37–46. https://doi.org/10.15587/1729-4061.2024.298567

- Vural, N., Algan-Cavuldak, Ö., Akay, M. A. (2024). Desirability Function Approach for the Optimization of Hydroalcoholic Solvent Extraction Conditions for Antioxidant Compounds from Olive Leaves. Anais Da Academia Brasileira de Ciências, 96 (1). https://doi.org/10.1590/0001-3765202420230602

- Vasylyshyna, O. (2019). Application of multicriteria optimization method to select the best varieties of frozen cherry fruit. Scientific Horizons, 80 (7), 70–74. https://doi.org/10.33249/2663-2144-2019-80-7-70-74

- Silva, V., Pereira, S., Vilela, A., Bacelar, E., Guedes, F., Ribeiro, C. et al. (2021). Preliminary Insights in Sensory Profile of Sweet Cherries. Foods, 10 (3), 612. https://doi.org/10.3390/foods10030612

- Ivanova, I., Kryvonos, I., Shleina, L., Taranenko, G., Gerasko, T. (2019). Multicriteria Optimization of Quality Indicators of Sweet Cherry Fruits of Ukrainian Selection During Freezing and Storage. Modern Development Paths of Agricultural Production, 707–717. https://doi.org/10.1007/978-3-030-14918-5_69

- Hutsol, T., Priss, O., Ivanova, I., Serdуuk, M., Cupiał, M., Tymoshchuk, T. et al. (2024). Effectiveness of Cooling Methods in Reducing Losses During Cherry Storage. Agricultural Engineering, 28 (1), 321–340. https://doi.org/10.2478/agriceng-2024-0020

- Ivanova, I., Serdyuk, M., Malkina, V., Tymoshchuk, T., Shlieina, L., Pokoptseva, L. et al. (2023). The effects of weather factors on titrating acids accumulation in sweet cherry fruits. Future of Food: Journal on Food, Agriculture & Society, 11 (1), 1–15. https://doi.org/10.17170/kobra-202210056938

- Mineață, I., Murariu, O. C., Sîrbu, S., Tallarita, A. V., Caruso, G., Jităreanu, C. D. (2024). Effects of Ripening Phase and Cultivar under Sustainable Management on Fruit Quality and Antioxidants of Sweet Cherry. Horticulturae, 10 (7), 720. https://doi.org/10.3390/horticulturae10070720

- Fonseca, L. R. S., Silva, G. R., Luís, Â., Cardoso, H. J., Correia, S., Vaz, C. V. et al. (2021). Sweet Cherries as Anti-Cancer Agents: From Bioactive Compounds to Function. Molecules, 26 (10), 2941. https://doi.org/10.3390/molecules26102941

- Perju, I., Mineață, I., Sîrbu, S., Golache, I. E., Ungureanu, I. V., Jităreanu, C. D. (2025). Fruit Quality and Production Parameters of Some Bitter Cherry Cultivars. Horticulturae, 11 (1), 87. https://doi.org/10.3390/horticulturae11010087

- Vilela, A., Sobreira, C., Abraão, A. S., Lemos, A. M., Nunes, F. M. (2016). Texture Quality of Candied Fruits as Influenced by Osmotic Dehydration Agents. Journal of Texture Studies, 47 (3), 239–252. https://doi.org/10.1111/jtxs.12177

- Patel, S., Torres, C. A., Tang, J., Sablani, S., Munson, C. L. (2025). Influence of fruit size on sweet cherry respiration: a multi-cultivar analysis introducing the size factor. Journal of Food Measurement and Characterization. https://doi.org/10.1007/s11694-025-03235-4

- Ropelewska, E., Konopacka, D., Piecko, J. (2023). The Quality Assessment of Sour Cherries Dried Using an Innovative Simultaneous Osmotic–Microwave–Vacuum Approach Based on Image Textures, Color Parameters, and Sensory Attributes. Agriculture, 14 (1), 54. https://doi.org/10.3390/agriculture14010054

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Іryna Ivanova, Marina Serdyuk, Tetiana Tymoshchuk, Svitlana Stotska, Viktor Smahlii, Natalia Slobodyanyuk, Nataliia Golembovska, Nadiia Zahorko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.