Determining the heat and mass exchange efficiency of a scraper heat exchanger for heating food semi-finished products

DOI:

https://doi.org/10.15587/1729-4061.2025.335509Keywords:

scraper heat exchanger, film flow, heat transfer, hinged blade, energy efficiency, fruit and berry pureeAbstract

This study's object is the process of heating fruit and berry purees made from apple, apricot, and honeysuckle.

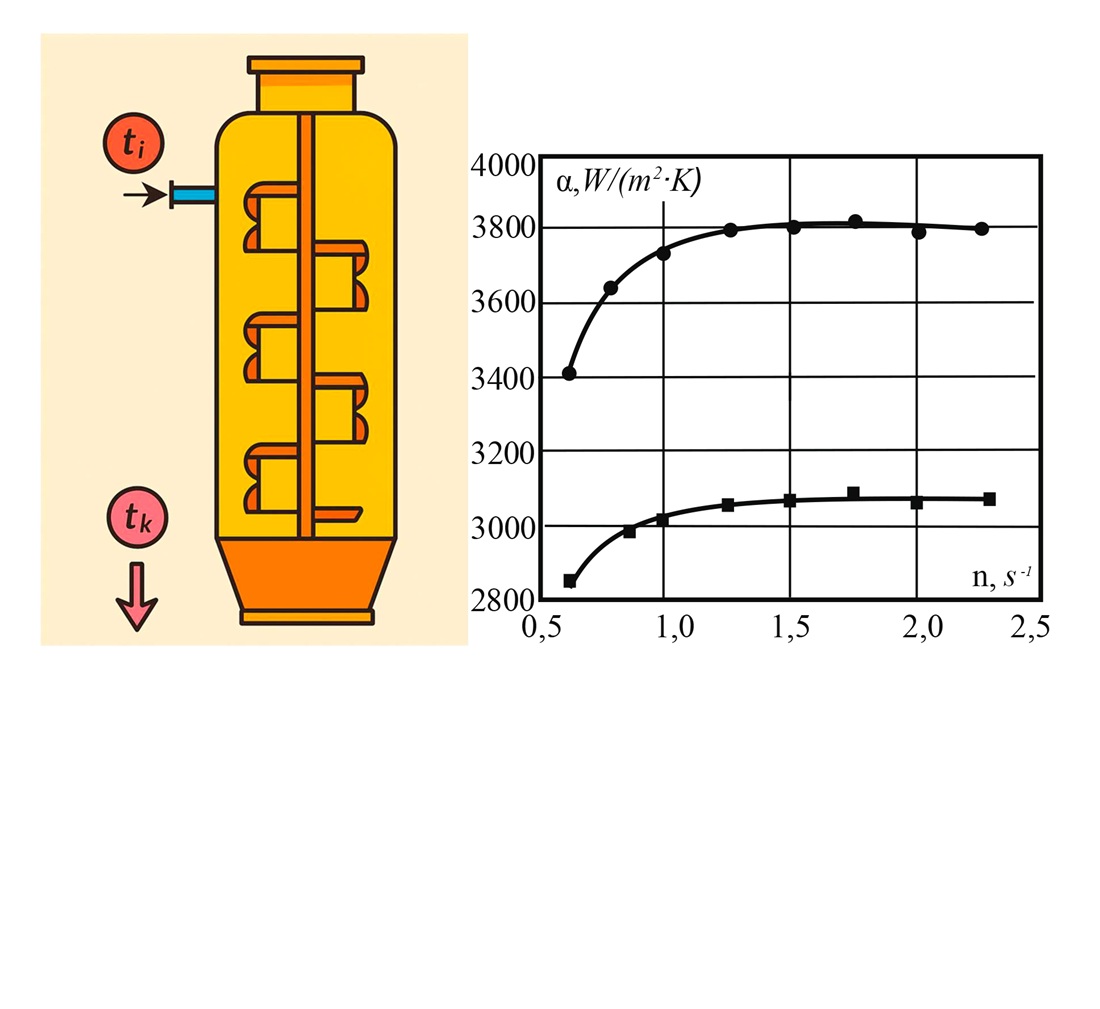

This paper reports an improved structure of a scraper heat exchanger for heating viscous liquid food products based on fruit and berry raw materials (purees, pastes). One of the main elements of the modernization is heating with a flexible film resistive electric heater of the radiant type instead of the conventional steam system, which has made it possible to eliminate steam fittings and reduce energy consumption. Additional equipment of the heat exchanger with a hinged blade with a remote plate enables turbulization of the product flow in the heat exchange zone, contributing to the formation of a stable film flow on the heating surface, which significantly improves the efficiency of heat transfer.

The experimental and computational studies revealed the dependence of the heat transfer coefficient on raw material consumption and the frequency of rotation of the apparatus shaft. It was established that the heat transfer coefficient depends on the product flow rate and, after reaching the maximum (13…15) 10–3 kg/s, it decreases. The influence of rotor speed is less significant and is manifested mainly during the transition from 1.0 to 1.5 s⁻1. Comparative analysis revealed that the use of an improved blade with a remote plate makes it possible to increase the heat transfer coefficient by 1.2 times compared to the conventional design. Calculations of specific heat consumption showed its decrease from 250 to 222 kJ/kg, which is a saving of 12.5%.

The proposed structural solutions make it possible to ensure the stability of temperature regimes, reduce energy consumption, improve the quality of heat treatment and process automation. This is especially important for the processing of heat-sensitive and dense products in the food industry

References

- Kasabova, K., Samokhvalova, O., Zagorulko, A., Zahorulko, A., Babaiev, S., Bereza, O. et al. (2022). Improvement of Turkish delight production technology using a developed multi-component fruit and vegetable paste. Eastern-European Journal of Enterprise Technologies, 6 (11 (120)), 51–59. https://doi.org/10.15587/1729-4061.2022.269393

- Samokhvalova, O., Kasabova, K., Shmatchenko, N., Zagorulko, A., Zahorulko, A. (2021). Improving the marmalade technology by adding a multicomponent fruit-and-berry paste. Eastern-European Journal of Enterprise Technologies, 6 (11 (114)), 6–14. https://doi.org/10.15587/1729-4061.2021.245986

- Zagorulko, A., Shydakova-Kameniuka, O., Kasabova, K., Zahorulko, A., Budnyk, N., Kholobtseva, I. et al. (2023). Substantiating the technology of cream-whipped candy masses with the addition of berry and fruit paste. Eastern-European Journal of Enterprise Technologies, 3 (11 (123)), 50–59. https://doi.org/10.15587/1729-4061.2023.279287

- Samokhvalova, O. V., Kasabova, K. R., Oliinyk, S. H. (2014). The influence of the enriching additives on the dough structure formation and baked muffins. Eastern-European Journal of Enterprise Technologies, 1 (10 (67), 32–36. https://doi.org/10.15587/1729-4061.2014.20024

- Kasabova, K., Sabadash, S., Mohutova, V., Volokh, V., Poliakov, A., Lazarieva, T. et al. (2020). Improvement of a scraper heat exchanger for pre-heating plant-based raw materials before concentration. Eastern-European Journal of Enterprise Technologies, 3 (11 (105)), 6–12. https://doi.org/10.15587/1729-4061.2020.202501

- Zahorulko, A., Zagorulko, A., Kasabova, K., Liashenko, B., Postadzhiev, A., Sashnova, M. (2022). Improving a tempering machine for confectionery masses. Eastern-European Journal of Enterprise Technologies, 2 (11 (116)), 6–11. https://doi.org/10.15587/1729-4061.2022.254873

- Li, F., Chen, G., Zhang, B., Fu, X. (2017). Current applications and new opportunities for the thermal and non-thermal processing technologies to generate berry product or extracts with high nutraceutical contents. Food Research International, 100, 19–30. https://doi.org/10.1016/j.foodres.2017.08.035

- Qiu, J., Kloosterboer, K., Guo, Y., Boom, R. M., Schutyser, M. A. I. (2019). Conductive thin film drying kinetics relevant to drum drying. Journal of Food Engineering, 242, 68–75. https://doi.org/10.1016/j.jfoodeng.2018.08.021

- Fayolle, F., Belhamri, R., Flick, D. (2013). Residence time distribution measurements and simulation of the flow pattern in a scraped surface heat exchanger during crystallisation of ice cream. Journal of Food Engineering, 116 (2), 390–397. https://doi.org/10.1016/j.jfoodeng.2012.12.009

- Błasiak, P., Pietrowicz, S. (2017). An experimental study on the heat transfer performance in a batch scraped surface heat exchanger under a turbulent flow regime. International Journal of Heat and Mass Transfer, 107, 379–390. https://doi.org/10.1016/j.ijheatmasstransfer.2016.11.049

- Crespí-Llorens, D., Vicente, P., Viedma, A. (2018). Experimental study of heat transfer to non-Newtonian fluids inside a scraped surface heat exchanger using a generalization method. International Journal of Heat and Mass Transfer, 118, 75–87. https://doi.org/10.1016/j.ijheatmasstransfer.2017.10.115

- Imran, A., Rana, M. A., Siddiqui, A. M. (2018). Study of a Eyring – Powell Fluid in a Scraped Surface Heat Exchanger. International Journal of Applied and Computational Mathematics, 4 (1). https://doi.org/10.1007/s40819-017-0436-z

- Martínez, D. S., Solano, J. P., Vicente, P. G., Viedma, A. (2019). Flow pattern analysis in a rotating scraped surface plate heat exchanger. Applied Thermal Engineering, 160, 113795. https://doi.org/10.1016/j.applthermaleng.2019.113795

- Błasiak, P., Pietrowicz, S. (2019). A numerical study on heat transfer enhancement via mechanical aids. International Journal of Heat and Mass Transfer, 140, 203–215. https://doi.org/10.1016/j.ijheatmasstransfer.2019.05.116

- Acosta, C. A., Yanes, D., Bhalla, A., Guo, R., Finol, E. A., Frank, J. I. (2020). Numerical and experimental study of the glass-transition temperature of a non-Newtonian fluid in a dynamic scraped surface heat exchanger. International Journal of Heat and Mass Transfer, 152, 119525. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119525

- Hernández-Parra, O. D., Plana-Fattori, A., Alvarez, G., Ndoye, F.-T., Benkhelifa, H., Flick, D. (2018). Modeling flow and heat transfer in a scraped surface heat exchanger during the production of sorbet. Journal of Food Engineering, 221, 54–69. https://doi.org/10.1016/j.jfoodeng.2017.09.027

- Kowalski, K., Błasiak, P., Pietrowicz, S. (2025). A review of scraped surface heat exchangers: Parameters describing thermal-fluid processes, influence of their internal geometric parameters and energy consumption. International Journal of Heat and Mass Transfer, 236, 126336. https://doi.org/10.1016/j.ijheatmasstransfer.2024.126336

- Dongellini, M., Martino, G., Naldi, C., Lorente, S., Morini, G. L. (2025). Experimental study on the heat transfer performance of finned-tube heat exchangers in latent thermal energy storages: Effects of PCM types and operating conditions. Applied Thermal Engineering, 271, 126273. https://doi.org/10.1016/j.applthermaleng.2025.126273

- Soni, M., Saurabh, Raha, A., Rao, A. S., Adak, A. K. (2025). Experimental & modeling studies on novel scraped surface falling film crystallizer for freeze desalination. Desalination and Water Treatment, 321, 100927. https://doi.org/10.1016/j.dwt.2024.100927

- Cao, Z., Luo, L., Yang, X., Yan, H., Du, W. (2025). Effects of turning vane on flow control and heat transfer in ribbed two-pass channel with varied rib patterns. International Journal of Thermal Sciences, 207, 109342. https://doi.org/10.1016/j.ijthermalsci.2024.109342

- Faure, E., Shcherba, A., Stupka, B., Voronenko, I., Baikenov, A.; Faure, E., Danchenko, O., Bondarenko, M., Tryus, Y., Bazilo, C., Zaspa, G. (Eds.) (2023). A Method for Reliable Permutation Transmission in Short-Packet Communication Systems. Information Technology for Education, Science, and Technics. Cham: Springer, 177–195. https://doi.org/10.1007/978-3-031-35467-0_12

- Kolosok, S., Lyeonov, S., Voronenko, I., Goncharenko, O., Maksymova, J., Chumak, O. (2022). Sustainable business models and IT innovation: The case of the REMIT. Journal of Information Technology Management, 14, 147–156. https://doi.org/10.22059/JITM.2022.88894

- Vakuum-aparat MZS-320, MZS-241 Vakuum-aparaty dlia kharchovoi promyslovosti. All-Biz. Available at: https://ua.all.biz/uk/vakuum-aparat-mzs-320-mzs-241-vakuum-aparaty-dlya-g2258596

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Aleksey Zagorulko, Kateryna Kasabova, Anastasiia Shevchenko, Dmytro Dmytrevskyi, Yuliia Levchenko, Olena Kalashnyk, Vitalii Koshulko, Aleksey Gromov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.