Розробка гідрогелів крохмалю та альгінату саго для 3D-друку харчових продуктів методом екструзії

DOI:

https://doi.org/10.15587/1729-4061.2025.336896Ключові слова:

3D-друк харчових продуктів, розрідження при зсуві, модуль зберігання, природний крохмаль-альгінат, саговий крохмальАнотація

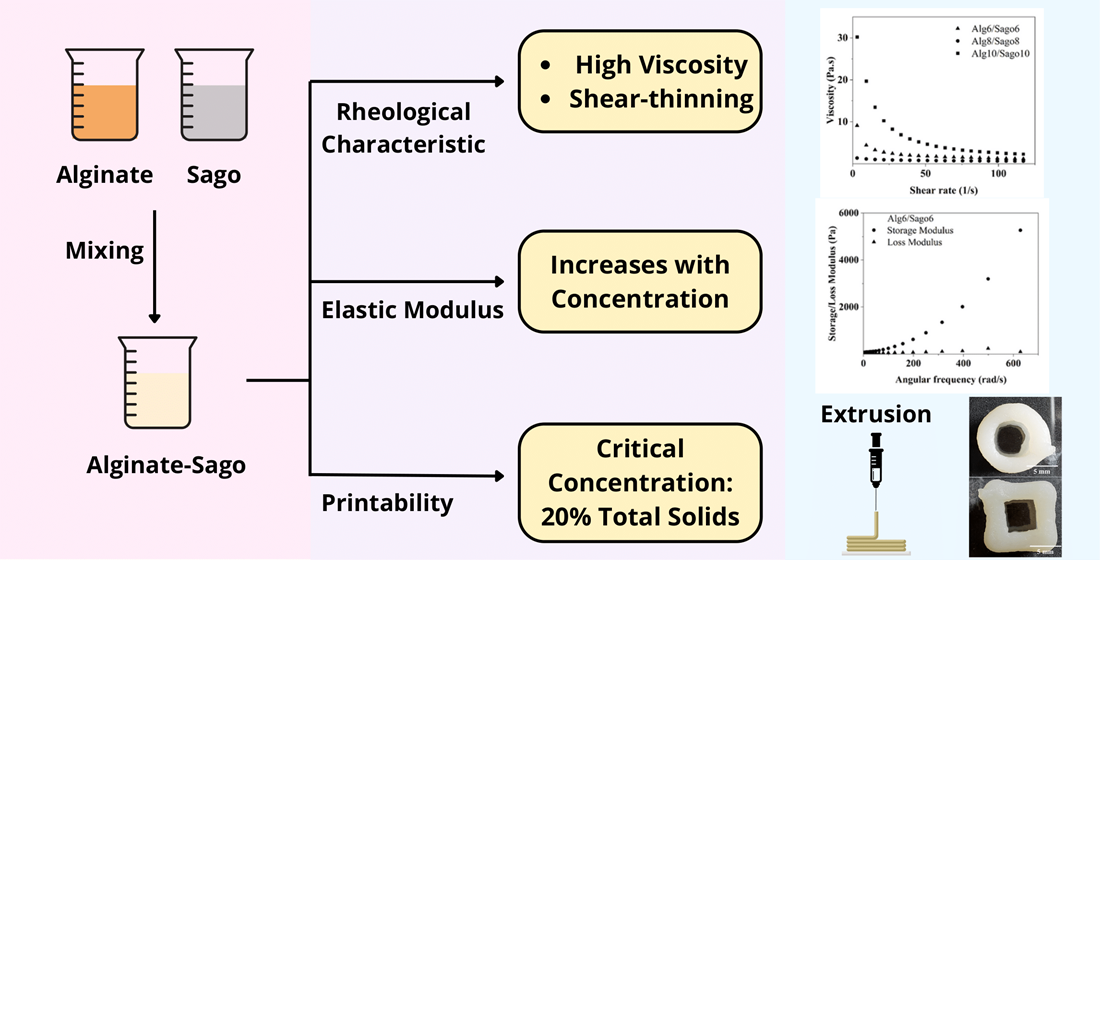

Інтеграція харчового крохмалю в технології 3D-друку має значний потенціал для створення індивідуальних, стійких та збагачених поживними речовинами харчових продуктів. У цьому рукописі досліджується розробка нових харчових чорнил на основі сагового крохмалю та альгінату, зокрема, їхня реологічна поведінка, придатність для друку та потенціал застосування для 3D-друку харчових продуктів методом екструзії. Індонезія, де знаходиться понад половина світових сагових лісів (1,28 мільйона гектарів), недостатньо використовує цю місцеву рослину. Однак, залишаються проблеми із забезпеченням структурної стабільності, відтворюваності та функціональних характеристик. Основною проблемою, що розглядається, є визначення відповідних гідрогелевих рецептур, які забезпечують як надійну придатність для друку, так і структурну цілісність після друку. Це дослідження встановлює, що успішний 3D-друк альгінат-сагових гідрогелів вимагає критичного порогу концентрації 20% альгінату/саго. Примітною особливістю є значна розбіжність між теоретичними реологічними прогнозами та експериментальними результатами для композитів середнього класу (наприклад, Alg6/Sago6 та Alg8/Sago8), що підкреслює обмеження сучасних реологічних моделей. Саговий крохмаль, завдяки високому вмісту амілози та сприятливій здатності до розрідження при зсуві, забезпечує чудову друкованість та продуктивність при зберіганні. Хоча включення саго значно покращує здатність до розрідження при зсуві та дозволяє ефективно модулювати в'язкість, модуль зберігання виявився більш прогностичним для друкованості, ніж параметри в'язкості. Ці результати дають практичне уявлення про оптимізацію крохмалю для підтримки структурної точності. Кругла та кубічна форма друку висотою 10 см була досягнута за допомогою лінійного нанесення близько 0,5 мм з 90% точністю шаблону проектування

Посилання

- Whulanza, Y., Arsyan, R., Saragih, A. S. (2018). Characterization of hydrogel printer for direct cell-laden scaffolds. AIP Conference Proceedings. https://doi.org/10.1063/1.5023972

- Sun, J., Zhou, W., Yan, L., Huang, D., Lin, L. (2018). Extrusion-based food printing for digitalized food design and nutrition control. Journal of Food Engineering, 220, 1–11. https://doi.org/10.1016/j.jfoodeng.2017.02.028

- Shen, D., Zhang, M., Mujumdar, A. S., Li, J. (2023). Advances and application of efficient physical fields in extrusion based 3D food printing technology. Trends in Food Science & Technology, 131, 104–117. https://doi.org/10.1016/j.tifs.2022.11.017

- Habibi, H., Khosravi-Darani, K. (2017). Effective variables on production and structure of xanthan gum and its food applications: A review. Biocatalysis and Agricultural Biotechnology, 10, 130–140. https://doi.org/10.1016/j.bcab.2017.02.013

- Udo, T., Mummaleti, G., Mohan, A., Singh, R. K., Kong, F. (2023). Current and emerging applications of carrageenan in the food industry. Food Research International, 173, 113369. https://doi.org/10.1016/j.foodres.2023.113369

- Tahir, H. E., Xiaobo, Z., Mahunu, G. K., Arslan, M., Abdalhai, M., Zhihua, L. (2019). Recent developments in gum edible coating applications for fruits and vegetables preservation: A review. Carbohydrate Polymers, 224, 115141. https://doi.org/10.1016/j.carbpol.2019.115141

- Mudgil, D., Barak, S., Khatkar, B. S. (2011). Guar gum: processing, properties and food applications – A Review. Journal of Food Science and Technology, 51 (3), 409–418. https://doi.org/10.1007/s13197-011-0522-x

- Yang, D., Yuan, Y., Wang, L., Wang, X., Mu, R., Pang, J. et al. (2017). A Review on Konjac Glucomannan Gels: Microstructure and Application. International Journal of Molecular Sciences, 18 (11), 2250. https://doi.org/10.3390/ijms18112250

- Cui, Y., Li, C., Guo, Y., Liu, X., Zhu, F., Liu, Z. et al. (2022). Rheological & 3D printing properties of potato starch composite gels. Journal of Food Engineering, 313, 110756. https://doi.org/10.1016/j.jfoodeng.2021.110756

- Ehara, H., Toyoda, Y., Johnson, D. V. (Eds.) (2018). Sago Palm. Springer Singapore. https://doi.org/10.1007/978-981-10-5269-9

- Sumardiono, S., Rakhmawati, R. B. (2017). Physicochemical Properties of Sago Starch Under Various Modification Process: An Overview. Advanced Science Letters, 23 (6), 5789–5791. https://doi.org/10.1166/asl.2017.8833

- Whulanza, Y., Azadi, A., Supriadi, S., Rahman, S. F., Chalid, M., Irsyad, M. et al. (2022). Tailoring mechanical properties and degradation rate of maxillofacial implant based on sago starch/polylactid acid blend. Heliyon, 8 (1), e08600. https://doi.org/10.1016/j.heliyon.2021.e08600

- Yoon, Y., Kim, C. H., Lee, J. E., Yoon, J., Lee, N. K., Kim, T. H., Park, S.-H. (2019). 3D bioprinted complex constructs reinforced by hybrid multilayers of electrospun nanofiber sheets. Biofabrication, 11 (2), 025015. https://doi.org/10.1088/1758-5090/ab08c2

- Hirao, K., Kondo, T., Kainuma, K., Takahashi, S. (2021). Starch gel foods in cookery science: application of native starch and modified starches. Journal of Biorheology, 35 (1), 29–41. https://doi.org/10.17106/jbr.35.29

- Li, C. (2024). Unraveling the Complexities of Starch Retrogradation: Insights from Kinetics, Molecular Interactions, and Influences of Food Ingredients. Food Reviews International, 40 (9), 3159–3182. https://doi.org/10.1080/87559129.2024.2347467

- Wang, S., Li, C., Copeland, L., Niu, Q., Wang, S. (2015). Starch Retrogradation: A Comprehensive Review. Comprehensive Reviews in Food Science and Food Safety, 14 (5), 568–585. https://doi.org/10.1111/1541-4337.12143

- Feltre, G., Almeida, F. S., Sato, A. C. K., Dacanal, G. C., Hubinger, M. D. (2020). Alginate and corn starch mixed gels: Effect of gelatinization and amylose content on the properties and in vitro digestibility. Food Research International, 132, 109069. https://doi.org/10.1016/j.foodres.2020.109069

- Ramírez, C., Millon, C., Nuñez, H., Pinto, M., Valencia, P., Acevedo, C., Simpson, R. (2015). Study of effect of sodium alginate on potato starch digestibility during in vitro digestion. Food Hydrocolloids, 44, 328–332. https://doi.org/10.1016/j.foodhyd.2014.08.023

- Zhong, Q., Chen, Y., Zhang, X., Yang, G., Jin, W., Peng, D., Huang, Q. (2024). Correlation between 3D printability and rheological properties of biopolymer fluid: A case study of alginate-based hydrogels. Journal of Food Engineering, 370, 111970. https://doi.org/10.1016/j.jfoodeng.2024.111970

- Ji, H., Zhao, J., Chen, J., Shimai, S., Zhang, J., Liu, Y. et al. (2022). A novel experimental approach to quantitatively evaluate the printability of inks in 3D printing using two criteria. Additive Manufacturing, 55, 102846. https://doi.org/10.1016/j.addma.2022.102846

- Cui, Y., Yang, F., Wang, C., Blennow, A., Li, C., Liu, X. (2024). 3D Printing windows and rheological properties for normal maize starch/sodium alginate composite gels. Food Hydrocolloids, 146, 109178. https://doi.org/10.1016/j.foodhyd.2023.109178

- Yang, F., Zhang, M., Bhandari, B. (2015). Recent development in 3D food printing. Critical Reviews in Food Science and Nutrition, 57 (14), 3145–3153. https://doi.org/10.1080/10408398.2015.1094732

- Whulanza, Y., Hidayaturrahmi, P., Kurniawati, T., AJ, R. (2017). Realization and testing of multi-material 3D printer for bone scaffold fabrication. AIP Conference Proceedings, 1817, 040001. https://doi.org/10.1063/1.4976786

- Fonkwe, L. G., Narsimhan, G., Cha, A. S. (2003). Characterization of gelation time and texture of gelatin and gelatin–polysaccharide mixed gels. Food Hydrocolloids, 17 (6), 871–883. https://doi.org/10.1016/s0268-005x(03)00108-5

- Yan, N., Yang, L., Xiao, X., Huang, P., Shu, C., Song, S., Tan, H. (2025). Research on Structural–Mechanical Property of Rice Starch Gels for Food 3D Printing and Flexible Sensing. Journal of Food Process Engineering, 48 (5). https://doi.org/10.1111/jfpe.70126

- Okazaki, M. (2018). The Structure and Characteristics of Sago Starch. Sago Palm, 247–259. https://doi.org/10.1007/978-981-10-5269-9_18

- Du, C., Jiang, F., Jiang, W., Ge, W., Du, S. (2020). Physicochemical and structural properties of sago starch. International Journal of Biological Macromolecules, 164, 1785–1793. https://doi.org/10.1016/j.ijbiomac.2020.07.310

- Nishiyama, S., Okazaki, M., Katsumi, N., Honda, Y., Tsujimoto, M. (2015). Surface charge on sago starch granules. Sago Palm, 23 (2), 77–83. Available at: https://www.sagopalmsociety.com/_files/ugd/3f58e5_4142a53f161840f68dc865bd28bed78f.pdf

- Singh, J., Singh, N. (2003). Studies on the morphological and rheological properties of granular cold water soluble corn and potato starches. Food Hydrocolloids, 17 (1), 63–72. https://doi.org/10.1016/s0268-005x(02)00036-x

- Pérez, E. E., Breene, W. M., Bahnassey, Y. A. (1998). ariations in the Gelatinization Profiles of Cassava, Sagu and Arrowroot Native Starches as Measured with Different Thermal and Mechanical Methods. Starch - Stärke, 50 (2-3), 70–72. https://doi.org/10.1002/(sici)1521-379x(199803)50:2/3<70::aid-star70>3.0.co;2-u

- Ronda, F., Roos, Y. H. (2008). Gelatinization and freeze-concentration effects on recrystallization in corn and potato starch gels. Carbohydrate Research, 343 (5), 903–911. https://doi.org/10.1016/j.carres.2008.01.026

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Doohan Taqdissillah, Muhammad Irsyad, Yudan Whulanza

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.