Виявлення міцності рами напіввагона із рогатками в конструкції для підвищення енергоефективності його експлуатації

DOI:

https://doi.org/10.15587/1729-4061.2025.340014Ключові слова:

залізничний транспорт, напіввагон, рама напіввагона, удосконалення рами, міцність рами, енергоефективність конструкціїАнотація

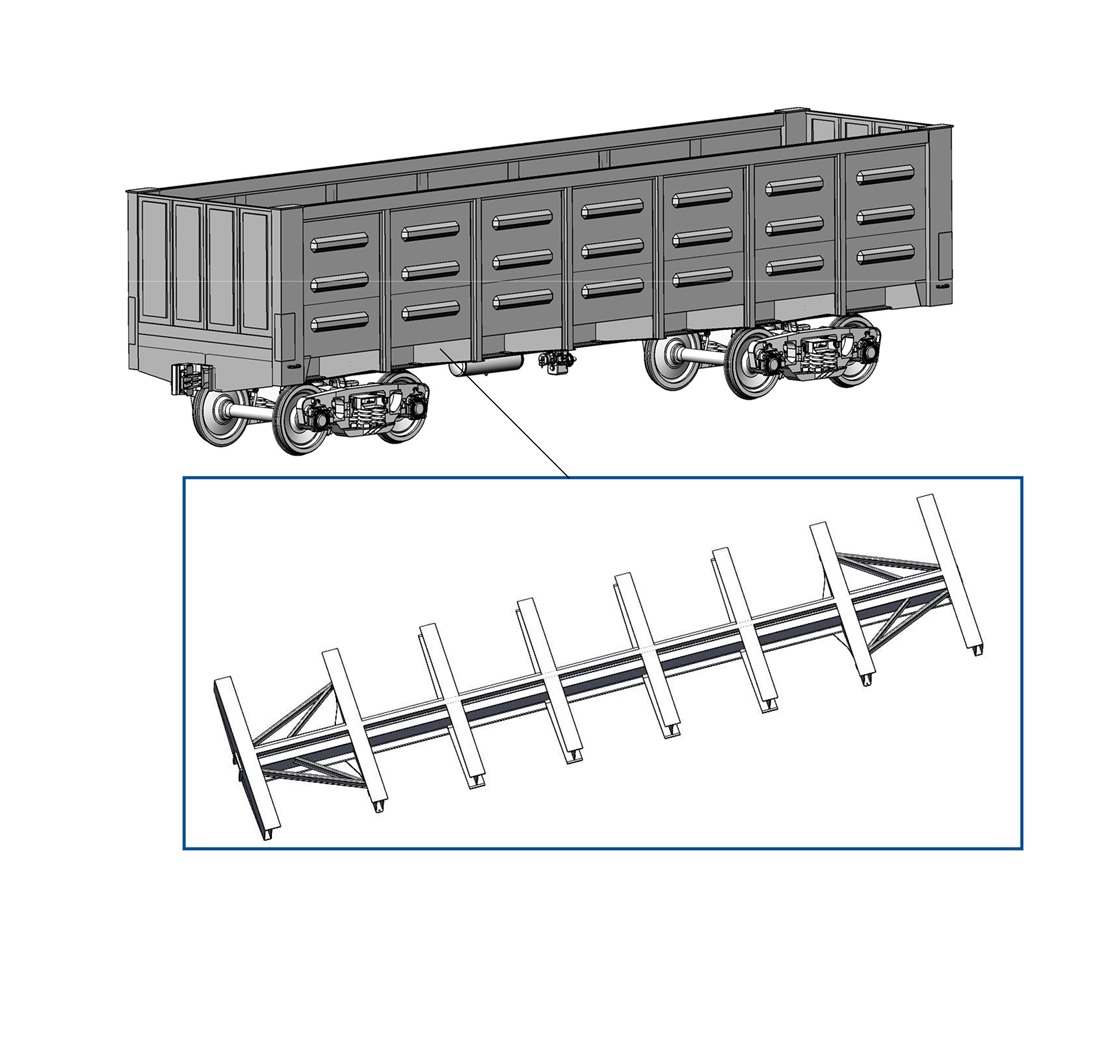

Об’єктом дослідження є процеси сприйняття та перерозподілу навантажень в рамі напіввагона із рогатками в конструкції при експлуатаційних навантаженнях. Проблема, що вирішувалась в рамках дослідження, полягає у зменшенні навантаженості рами напіввагона в експлуатації шляхом встановлення у її консольних частинах рогаток.

Для обґрунтування даного удосконалення проведено розрахунок на міцність рами напіввагона при основних схемах навантажень в експлуатації. Визначення динамічних навантажень, які діють на раму напіввагона, проведено математичним моделюванням. Результати розрахунків на міцність показали, що максимальні напруження в рамі виникають при І розрахунковому режимі. Однак ці напруження на 6% нижчі за ті, що мають місце в типовій конструкції рами.

Також в рамках дослідження проведено розрахунок на міцність рами напіввагона при перевезенні залізничним поромом. Встановлено, що міцність рами напіввагона забезпечується. Отримані розрахункові напруження на 4% нижче за ті, що виникають у типовій конструкції рами напіввагона.

Особливістю запропонованого удосконалення є те, що його реалізація є можливою на стадії модернізації вагонів, а не тільки виготовлення нових конструкцій.

Сферою практичного використання отриманих результатів є залізничний транспорт.

Умовою практичного впровадження результатів дослідження є сполучення рогатки із зонами розміщення передніх та задніх упорів автозчепів.

Результати проведеного дослідження сприятимуть покращенню міцності несучих конструкцій напіввагонів в експлуатації та зменшенню витрат на їх утримання. Також проведене дослідження сприятиме створенню напрацювань щодо проєктування вантажних вагонів із покращеними техніко-економічними показниками

Посилання

- Bulakh, M. (2025). Freight wagon body design with increased load capacity. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-025-97152-7

- Šťastniak, P., Smetanka, L., Moravčík, M. (2018). Structural Analysis of a Main Construction Assemblies of the New Wagon Prototype Type Zans. Manufacturing Technology, 18 (3), 510–517. https://doi.org/10.21062/ujep/130.2018/a/1213-2489/mt/18/3/510

- Caban, J., Vrabel, J., Górnicka, D., Nowak, R., Jankiewicz, M., Matijošius, J., Palka, M. (2023). Overview of Energy Harvesting Technologies Used in Road Vehicles. Energies, 16 (9), 3787. https://doi.org/10.3390/en16093787

- Lovska, A., Gerlici, J., Dižo, J., Pavliuchenkov, M. (2024). A Feasibility Study into the Use of Corrugated Beams in the Passenger Car Frame. Transport Means 2024. Proceedings of the 28th International Scientific Conference. https://doi.org/10.5755/e01.2351-7034.2024.p186-191

- Lovska, A., Gerlici, J., Dižo, J. (2025). Research of the possibility of using beams with corrugated walls in a passenger rail car frame. Scientific Reports, 15 (1). https://doi.org/10.1038/s41598-025-12783-0

- Kuczek, T. (2015). Application of manufacturing constraints to structural optimization of thin-walled structures. Engineering Optimization, 48 (2), 351–360. https://doi.org/10.1080/0305215x.2015.1017350

- Al-Sukhon, A., ElSayed, M. S. (2021). Design optimization of hopper cars employing functionally graded honeycomb sandwich panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 236 (8), 920–935. https://doi.org/10.1177/09544097211049640

- Jeong, D. Y., Tyrell, D. C., Carolan, M. E., Perlman, A. B. (2009). Improved Tank Car Design Development: Ongoing Studies on Sandwich Structures. 2009 Joint Rail Conference, 89–98. https://doi.org/10.1115/jrc2009-63025

- Lee, W. G., Kim, J.-S., Sun, S.-J., Lim, J.-Y. (2016). The next generation material for lightweight railway car body structures: Magnesium alloys. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 232 (1), 25–42. https://doi.org/10.1177/0954409716646140

- Lee, H.-A., Jung, S.-B., Jang, H.-H., Shin, D.-H., Lee, J. U., Kim, K. W., Park, G.-J. (2015). Structural-optimization-based design process for the body of a railway vehicle made from extruded aluminum panels. Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, 230 (4), 1283–1296. https://doi.org/10.1177/0954409715593971

- Gerlici, J., Lovska, A., Vatulia, G., Pavliuchenkov, M., Kravchenko, O., Solčanský, S. (2023). Situational Adaptation of the Open Wagon Body to Container Transportation. Applied Sciences, 13 (15), 8605. https://doi.org/10.3390/app13158605

- Koziar, M. M., Feshchuk, Yu. V., Parfeniuk, O. V. (2018). Kompiuterna hrafika: SolidWorks. Kherson: Oldi-plius, 252. Available at: https://ep3.nuwm.edu.ua/22175/1/Комп%27ютерна%20графіка.pdf

- Pustiulha, S. I., Samostian, V. R., Klak, Yu. V. (2018). Inzhenerna hrafika v SolidWorks. Lutsk: Vezha, 172. Available at: https://lib.lntu.edu.ua/sites/default/files/2021-02/Інженерна%20графіка%20в%20SolidWorks.pdf

- Gerlici, J., Lovska, A., Kozáková, K. (2025). Research into the Longitudinal Loading of an Improved Load-Bearing Structure of a Flat Car for Container Transportation. Designs, 9 (1), 12. https://doi.org/10.3390/designs9010012

- Gerlici, J., Lovska, A., Pavliuchenkov, M. (2024). Study of the Dynamics and Strength of the Detachable Module for Long Cargoes under Asymmetric Loading Diagrams. Applied Sciences, 14 (8), 3211. https://doi.org/10.3390/app14083211

- Stoilov, V., Simić, G., Purgić, S., Milković, D., Slavchev, S., Radulović, S., Maznichki, V. (2019). Comparative analysis of the results of theoretical and experimental studies of freight wagon Sdggmrss-twin. IOP Conference Series: Materials Science and Engineering, 664 (1), 012026. https://doi.org/10.1088/1757-899x/664/1/012026

- Lakshmikant, P., D V, R., Guha, S. (2025). Numerical investigation of the fatigue life of center sill of a BFNSM wagon. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications. https://doi.org/10.1177/14644207251345076

- Dižo, J., Blatnický, M., Sága, M., Harušinec, J., Gerlici, J., Legutko, S. (2020). Development of a New System for Attaching the Wheels of the Front Axle in the Cross-Country Vehicle. Symmetry, 12 (7), 1156. https://doi.org/10.3390/sym12071156

- Caban, J., Marczuk, A., Šarkan, B., Vrábel, J. (2015). Studies on operational wear of glycol-based brake fluid Badania eksploatacyjnego zużycia płynu hamulcowego wytworzonego na bazie glikolu. PRZEMYSŁ CHEMICZNY, 94 (10), 1802–1806. https://doi.org/10.15199/62.2015.10.30

- Dizo, J., Blatnicky, M. (2019). Evaluation of Vibrational Properties of a Three-wheeled Vehicle in Terms of Comfort. Manufacturing Technology, 19 (2), 197–203. https://doi.org/10.21062/ujep/269.2019/a/1213-2489/mt/19/2/197

- Kowalski, S., Cieślikowski, B., Barta, D., Dižo, J., Dittrich, A. (2023). Analysis of the Operational Wear of the Combustion Engine Piston Pin. Lubricants, 11 (3), 100. https://doi.org/10.3390/lubricants11030100

- Lovska, A., Gerlici, J., Dižo, J., Ishchuk, V. (2023). The Strength of Rail Vehicles Transported by a Ferry Considering the Influence of Sea Waves on Its Hull. Sensors, 24 (1), 183. https://doi.org/10.3390/s24010183

- Domin, Yu. V., Cherniak, H. Yu. (2003). Osnovy dynamiky vahoniv. Kyiv: KUETT, 269.

- Panchenko, S., Gerlici, J., Vatulia, G., Lovska, A., Ravlyuk, V., Harusinec, J. (2023). Studying the load of composite brake pads under high-temperature impact from the rolling surface of wheels. EUREKA: Physics and Engineering, 4, 155–167. https://doi.org/10.21303/2461-4262.2023.002994

- Kondratiev, A. V., Kovalenko, V. O. (2019). Optimization of design parameters of the main composite fairing of the launch vehicle under simultaneous force and thermal loading. Space Science and Technology, 25 (4), 3–21. https://doi.org/10.15407/knit2019.04.003

- Blatnický, M., Dižo, J., Gerlici, J., Sága, M., Lack, T., Kuba, E. (2020). Design of a robotic manipulator for handling products of automotive industry. International Journal of Advanced Robotic Systems, 17 (1). https://doi.org/10.1177/1729881420906290

- Vatulia, G. L., Lovska, A. O., Krasnokutskyi, Y. S. (2023). Research into the transverse loading of the container with sandwich-panel walls when transported by rail. IOP Conference Series: Earth and Environmental Science, 1254 (1), 012140. https://doi.org/10.1088/1755-1315/1254/1/012140

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2025 Alyona Lovska, Iraida Stanovska, Yevhen Pelypenko, Hanna Barsukova, Oleksandr Yurchenko

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.

Ліцензійний договір – це документ, в якому автор гарантує, що володіє усіма авторськими правами на твір (рукопис, статтю, тощо).

Автори, підписуючи Ліцензійний договір з ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР», мають усі права на подальше використання свого твору за умови посилання на наше видання, в якому твір опублікований. Відповідно до умов Ліцензійного договору, Видавець ПП «ТЕХНОЛОГІЧНИЙ ЦЕНТР» не забирає ваші авторські права та отримує від авторів дозвіл на використання та розповсюдження публікації через світові наукові ресурси (власні електронні ресурси, наукометричні бази даних, репозитарії, бібліотеки тощо).

За відсутності підписаного Ліцензійного договору або за відсутністю вказаних в цьому договорі ідентифікаторів, що дають змогу ідентифікувати особу автора, редакція не має права працювати з рукописом.

Важливо пам’ятати, що існує і інший тип угоди між авторами та видавцями – коли авторські права передаються від авторів до видавця. В такому разі автори втрачають права власності на свій твір та не можуть його використовувати в будь-який спосіб.