Determining the rational energy level for processing environments of different structures

DOI:

https://doi.org/10.15587/1729-4061.2025.341458Keywords:

vibration exciter, environment, discrete-continuous model, energy dissipation, amplitude of vibrations, frequencyAbstract

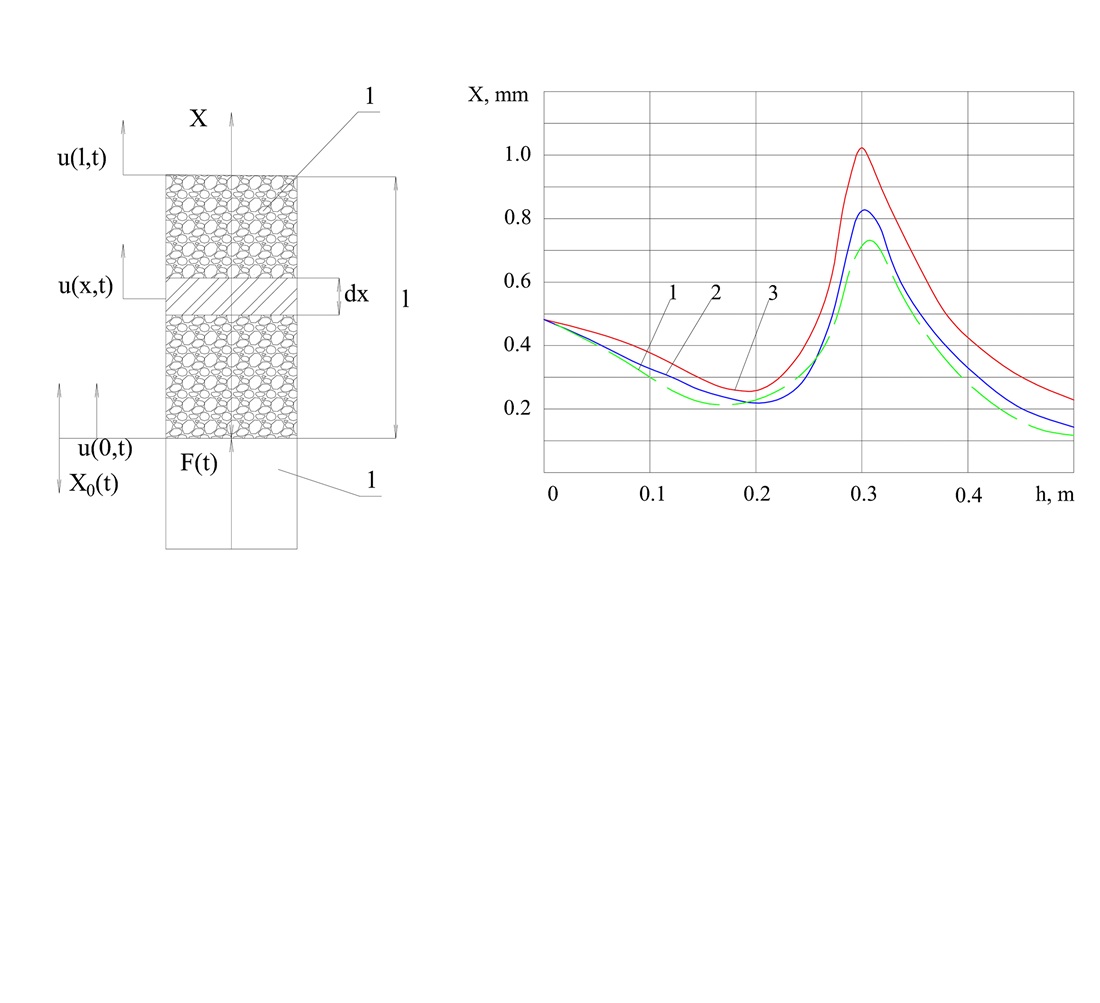

Vibration processing underlies many technological processes in various sectors of the national economy. The object of the study is a single common wave process of motion of the system, and the subject is the parameters and modes that provide a rational level of energy. At the same time, attention is focused on the use of energy-saving technologies. Most processes use energy-consuming technologies and equipment, the calculations of which are based on the application of formulas for determining energy on discrete and empirical dependencies. Such approaches do not reveal the essence of the material processing processes and cannot accurately estimate energy costs. This problem is solved in the work by determining the parameters and modes based on the conditions for implementing the synergy of the “vibration exciter – processing medium” system. This is the peculiarity and difference of the obtained research results. Discrete-continuous models have been developed taking into account the rheological properties of the media, and analytical solutions and experimental studies have allowed to determine the parameters of low-frequency and high-frequency actions on the processing medium. The work uses a method by which the combination of frequency and amplitude of vibrations determines the intensity of the vibration effect on the processing environment. The resistance of the technological environment to the movement of the working body of the vibration exciter, which consisted of inertial, elastic and dissipative parts, was determined. The study determined the qualitative and quantitative picture of the change in energy dissipation in specific materials and environments under different laws of their loading and processing. The energy level for processing technological environments in low-frequency and high-frequency modes was determined. The research methodology and analytical dependence of energy determination can be used for various environments under load

References

- Sotoudeh, Z. (2019). Entropy and Mixing Entropy for Weakly Nonlinear Mechanical Vibrating Systems. Entropy, 21 (5), 536. https://doi.org/10.3390/e21050536

- Bissembayev, K., Jomartov, A., Tuleshov, A., Dikambay, T. (2019). Analysis of the Oscillating Motion of a Solid Body on Vibrating Bearers. Machines, 7 (3), 58. https://doi.org/10.3390/machines7030058

- Hayashibe, M., Shimoda, S. (2022). Synergetic synchronized oscillation by distributed neural integrators to induce dynamic equilibrium in energy dissipation systems. Scientific Reports, 12 (1). https://doi.org/10.1038/s41598-022-21261-w

- Sun, Y., Vizzaccaro, A., Yuan, J., Salles, L. (2020). An extended energy balance method for resonance prediction in forced response of systems with non-conservative nonlinearities using damped nonlinear normal mode. Nonlinear Dynamics, 103 (4), 3315–3333. https://doi.org/10.1007/s11071-020-05793-2

- Nazarenko, I., Gaidaichuk, V., Dedov, O., Diachenko, O. (2018). Determination of stresses and strains in the shaping structure under spatial load. Eastern-European Journal of Enterprise Technologies, 6 (7 (96)), 13–18. https://doi.org/10.15587/1729-4061.2018.147195

- Son, K. J. (2025). Mathematical Modeling of High-Energy Shaker Mill Process with Lumped Parameter Approach for One-Dimensional Oscillatory Ball Motion with Collisional Heat Generation. Mathematics, 13 (3), 446. https://doi.org/10.3390/math13030446

- Liu, Z., Zhang, L., Zhao, L., Wu, Z., Guo, B. (2022). A Damage Model of Concrete including Hysteretic Effect under Cyclic Loading. Materials, 15 (14), 5062. https://doi.org/10.3390/ma15145062

- Cleante, V. G., Brennan, M. J., Gatti, G., Thompson, D. J. (2017). On the spectrum of rail vibration generated by a passing train. Procedia Engineering, 199, 2657–2662. https://doi.org/10.1016/j.proeng.2017.09.532

- AL-Shudeifat, M. A., Nasar, R. A. (2025). On rapid vibration suppression by nonlinear energy sink during first half cycle of oscillation. Communications in Nonlinear Science and Numerical Simulation, 142, 108534. https://doi.org/10.1016/j.cnsns.2024.108534

- Nazarenko, I., Gavryukov, O., Klyon, A., Ruchynsky, N. (2018). Determination of the optimal parameters of a tubular belt conveyor depending on such an economical. Eastern-European Journal of Enterprise Technologies, 3 (1 (93)), 34–42. https://doi.org/10.15587/1729-4061.2018.131552

- Luhovskyi, O., Bernyk, I., Gryshko, I., Abdulina, D., Zilinskyi, A. (2020). Mobile Equipment for Ultrasonic Cavitation Inactivation of Microorganisms in the Liquid Environment. Advances in Hydraulic and Pneumatic Drives and Control 2020, 272–281. https://doi.org/10.1007/978-3-030-59509-8_24

- Nazarenko, I., Bernyk, I., Dedov, O., Rogovskii, I., Ruchynskyi, M., Pereginets, I., Titova, L. (2021). Research of technical systems of processes of mixing materials. Dynamic Processes in Technological Technical Systems, 57–76. https://doi.org/10.15587/978-617-7319-49-7.ch4

- Bernyk, I., Luhovskyi, O., Wojcik, W., Shedreyeva, I., Karnakova, G. (2019). Theoretical investigations of the interaction of acoustic apparatus with technological environment working process. Przegląd Elektrotechniczny, 1 (4), 32–37. https://doi.org/10.15199/48.2019.04.06

- Kobus, Z., Krzywicka, M., Pecyna, A., Buczaj, A. (2021). Process Efficiency and Energy Consumption during the Ultrasound-Assisted Extraction of Bioactive Substances from Hawthorn Berries. Energies, 14 (22), 7638. https://doi.org/10.3390/en14227638

- Teoh, Y. H., Liew, S. Y., How, H. G., Yaqoob, H., Idroas, M. Y., Jamil, M. A. et al. (2025). Investigating sono-electrolysis for hydrogen generation and energy optimization. International Communications in Heat and Mass Transfer, 164, 108980. https://doi.org/10.1016/j.icheatmasstransfer.2025.108980

- Feng, J., Yan, T., Hou, Z. (2024). Numerical Simulation Study of Factors Influencing Ultrasonic Cavitation Bubble Evolution on Rock Surfaces during Ultrasonic-Assisted Rock Breaking. Water, 16 (16), 2234. https://doi.org/10.3390/w16162234

- Aliev, T., Korolev, I., Burdulenko, O., Alchinova, E., Subbota, A., Yasnov, M., Nosonovsky, M., Skorb, E. V. (2024). Automatic image processing of cavitation bubbles to analyze the properties of petroleum products. Digital Discovery, 3 (6), 1101–1107. https://doi.org/10.1039/d4dd00003j

- Langley, R. S., Hawes, D. H., Butlin, T., Ishii, Y. (2019). Response variance prediction using transient statistical energy analysis. The Journal of the Acoustical Society of America, 145 (2), 1088–1099. https://doi.org/10.1121/1.5090501

- Morton, J. A., Khavari, M., Priyadarshi, A., Kaur, A., Grobert, N., Mi, J. et al. (2023). Dual frequency ultrasonic cavitation in various liquids: High-speed imaging and acoustic pressure measurements. Physics of Fluids, 35 (1). https://doi.org/10.1063/5.0136469

- Zhu, X., Das, R. S., Bhavya, M. L., Garcia-Vaquero, M., Tiwari, B. K. (2024). Acoustic cavitation for agri-food applications: Mechanism of action, design of new systems, challenges and strategies for scale-up. Ultrasonics Sonochemistry, 105, 106850. https://doi.org/10.1016/j.ultsonch.2024.106850

- Nazarenko, I., Bernyk, I. (2021). Research of the processes of acoustic cavitation technology for processing dispersed media. Dynamic Processes in Technological Technical Systems, 94–109. https://doi.org/10.15587/978-617-7319-49-7.ch6

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Ivan Nazarenko, Oleg Dedov, Iryna Bernyk, Andrii Zapryvoda, Mykola Ruchynskyi, Andrii Bondarenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.