Design of a universal apparatus for heat treatment of meat and vegetable cooked and smoked products with the addition of dried semi-finished products of a high degree of readiness to the recipe

DOI:

https://doi.org/10.15587/1729-4061.2023.285406Keywords:

meat and vegetable cooked and smoked products, universal smoking device, hot and cold smoking, film electric heaterAbstract

The object of the study is the process of smoking a molded meat-vegetable product with the addition of a dried semi-finished product of a high degree of readiness based on Jerusalem artichoke, zucchini, and carrots.

Combined health products will satisfy the demand of end users for functional products of the new generation and will solve the technological problems of manufacturers in accordance with European competitiveness procedures. They will expand the offer of products with rational nutritional, taste, aesthetic characteristics that will meet the modern trends of craft producers, NoReCa business, and consumer expectations.

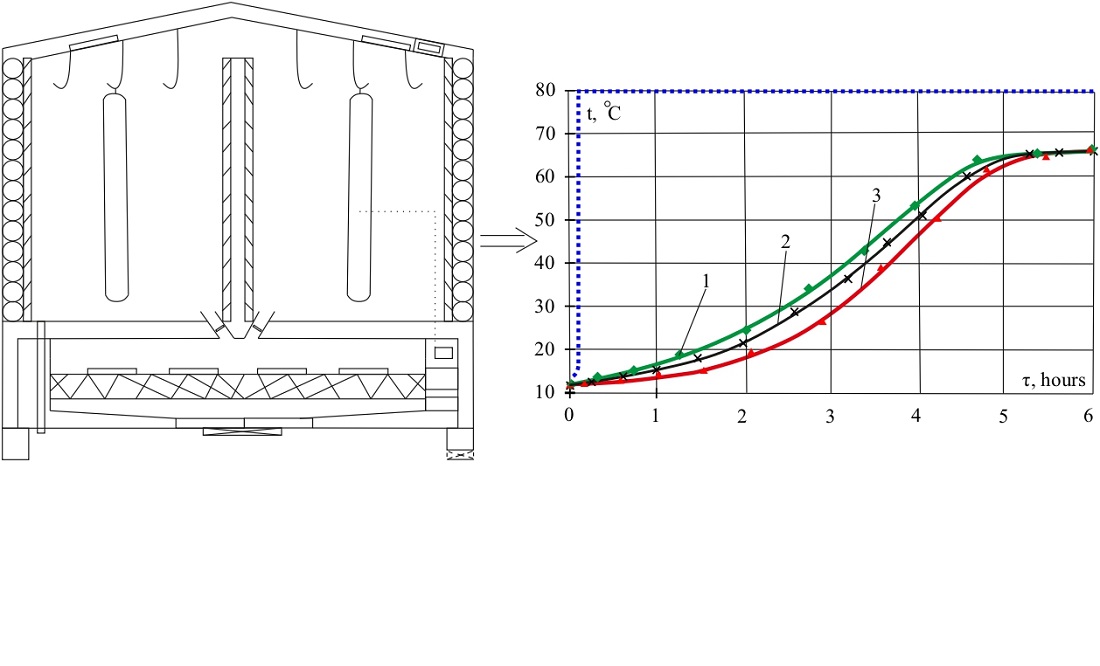

A universal device for heat treatment of meat and vegetable products under hot and cold smoking conditions has been designed based on a film-like resistive electric heater of the radiating type. The device uses Peltier elements placed on the outer surface of the smoke generator and, at a temperature of 45 °C, they form a low-voltage power supply (~3...4 W) from the conversion of secondary heat. Cold smoking is carried out in the temperature range up to 25 °С, provided that the outer surface of the heater is covered with a coil heat exchanger through which the coolant passes. During hot smoking, the air medium is in the heat exchanger (additional thermal insulation of the chamber).

The uniformity of the temperature field of the meat-vegetable product (meatloaf with a diameter of 0.08±0.01 m) during hot smoking has been confirmed, provided that the center of the loaf reaches 65 °C and the total duration of the process is 5.5 hours. The introduction of dried semi-finished products of a high degree of readiness into the recipe of meat loaves increases the yield of the product by 18 % and the mass fraction of protein by 25 %. The moisture retention capacity of the experimental meat product increases by 11 % with a 33 % decrease in calorie content, which indicates an improvement in its quality indicators compared to the analog

References

- Galanakis, C. M., Rizou, M., Aldawoud, T. M. S., Ucak, I., Rowan, N. J. (2021). Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. Trends in Food Science & Technology, 110, 193–200. doi: https://doi.org/10.1016/j.tifs.2021.02.002

- Munekata, P. E. S., Pérez-Álvarez, J. Á., Pateiro, M., Viuda-Matos, M., Fernández-López, J., Lorenzo, J. M. (2021). Satiety from healthier and functional foods. Trends in Food Science & Technology, 113, 397–410. doi: https://doi.org/10.1016/j.tifs.2021.05.025

- Toldrá, F. (2023). The storage and preservation of meat. III—Meat processing. Lawrie’s Meat Science, 281–314. doi: https://doi.org/10.1016/b978-0-323-85408-5.00002-9

- Savytska, N. L., Afanasieva, O. P. (2018). Marketynhova polityka pidpryiemstv na vitchyznianomu rynku miasa ta miasoproduktiv. Kharkiv: Vydavnytstvo Ivanchenka I. S., 344. Available at: https://dspace.nuft.edu.ua/jspui/bitstream/123456789/28869/3/meat%20.pdf

- Zahorulko, A., Cherevko, O., Zagorulko, A., Yancheva, M., Budnyk, N., Nakonechna, Y. et al. (2021). Design of an apparatus for low-temperature processing of meat delicacies. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 6–12. doi: https://doi.org/10.15587/1729-4061.2021.240675

- Halagarda, M., Wójciak, K. M. (2022). Health and safety aspects of traditional European meat products. A review. Meat Science, 184, 108623. doi: https://doi.org/10.1016/j.meatsci.2021.108623

- Meat Report 2023. Statista. Available at: https://www.statista.com/study/48827/meat-report/

- Tovarna struktura rozdribnoho tovarooborotu pidpryiemstv rozdribnoi torhivli. Available at: https://ukrstat.gov.ua/operativ/operativ2018/sr/tsrtp/tsrt_u_0918.htm

- Value of the global packaged & unpackaged meat snacks market 2019-2026 (2023). Available at: https://www.statista.com/statistics/1199651/global-packaged-and-unpackaged-meat-snacks-market-size/

- Serikkyzy, M., Jumabekova, G., Zheldybayeva, A., Matibayeva, A., Omirbay, R., Balev, D. (2022). Improving the organoleptic and structural-chemical properties of semi-smoked sausages. Saudi Journal of Biological Sciences, 29 (3), 1510–1514. doi: https://doi.org/10.1016/j.sjbs.2021.11.021

- McBey, D., Watts, D Johnstone, A. M. (2019). Nudging, formulating new products, and the lifecourse: A qualitative assessment of the viability of three methods for reducing Scottish meat consumption for health, ethical, and environmental reasons. Appetite, 142, 104349. doi: https://doi.org/10.1016/j.appet.2019.104349

- BusinesStat, 2020. Market analysis of sausages and meat specialties in Russia in 2014–2018, forecast for 2019–2023.

- Altenburg, D., Spruyt, A. (2022). Predicting meat consumption from concurrent, automatic appraisals: Introducing nuance to product appraisals. Appetite, 170, 105847. doi: https://doi.org/10.1016/j.appet.2021.105847

- Cherevko, O., Mikhaylov, V., Zahorulko, A., Zagorulko, A., Gordienko, I. (2021). Development of a thermal-radiation single-drum roll dryer for concentrated food stuff. Eastern-European Journal of Enterprise Technologies, 1 (11 (109)), 25–32. doi: https://doi.org/10.15587/1729-4061.2021.224990

- Sikorski, Z. E. (2016). Smoked Foods: Principles and Production. Encyclopedia of Food and Health, 1–5. doi: https://doi.org/10.1016/b978-0-12-384947-2.00630-9

- Illippangama, A. U., Jayasena, D. D., Jo, C., Mudannayake, D. C. (2022). Inulin as a functional ingredient and their applications in meat products. Carbohydrate Polymers, 275, 118706. doi: https://doi.org/10.1016/j.carbpol.2021.118706

- Zahorulko, A., Zagorulko, A., Yancheva, M., Serik, M., Sabadash, S., Savchenko-Pererva, M. (2019). Development of the plant for low-temperature treatment of meat products using ir-radiation. Eastern-European Journal of Enterprise Technologies, 1 (11 (97)), 17–22. doi: https://doi.org/10.15587/1729-4061.2019.154950

- Sosa-Morales, M. E., Orzuna-Espíritu, R.Vélez-Ruiz, J. F. (2006). Mass, thermal and quality aspects of deep-fat frying of pork meat. Journal of Food Engineering, 77 (3), 731–738. doi: https://doi.org/10.1016/j.jfoodeng.2005.07.033

- Sebastian, P., Bruneau, D., Collignan, A., Rivier, M. (2005). Drying and smoking of meat: heat and mass transfer modeling and experimental analysis. Journal of Food Engineering, 70 (2), 227–243. doi: https://doi.org/10.1016/j.jfoodeng.2004.10.002

- Wang, S., Guan, R., Huang, H., Yang, K., Cai, M Chen, D. (2021). Effects of Different Smoking Materials and Methods on the Quality of Chinese Traditional Bacon (Larou). Journal of Food Protection, 84 (3), 359–367. doi: https://doi.org/10.4315/jfp-20-223

- Ledesma, E., Laca, A., Rendueles, M., Díaz, M. (2016). Texture, colour and optical characteristics of a meat product depending on smoking time and casing type. LWT - Food Science and Technology, 65, 164–172. doi: https://doi.org/10.1016/j.lwt.2015.07.077

- Janardhanan, R., Huerta-Leidenz, N., Ibañez, F. C., Beriain, M. J. (2023). High-pressure processing and sous-vide cooking effects on physicochemical properties of meat-based, plant-based and hybrid patties. LWT, 173, 114273. doi: https://doi.org/10.1016/j.lwt.2022.114273

- Kasiyanchuk, V. D. (2014). Sukhyi produkt topinambura – efektyvnyi napivfabrykat dlia vyrobnytstva produktsiyi likuvalno-profilaktychnoho pryznachennia. Halytskyi likarskykh visnyk, 21 (3), 103–104. Available at: http://nbuv.gov.ua/UJRN/glv_2014_21_3_41

- Telezhenko, L. N., Bezusov, A. T. (2004). Biologicheski aktivnye veschestva fruktov i ovoschey i ikh sokhranenie pri pererabotke. Odessa: «Optimum», 268.

- Yudina, T., Nazarenko, I. (2016). Technological parameters and modes of getting mashed zucchini with specified functional and technological properties. Pratsi TDATU, 1 (16), 142–149. Available at: http://elibrary.donnuet.edu.ua/84/1/Yud%D1%96na_article_23_02_2016.pdf.pdf

- Afoakwah, N. A., Dong, Y., Zhao, Y., Xiong, Z., Owusu, J., Wang, Y., Zhang, J. (2015). Characterization of Jerusalem artichoke (Helianthus tuberosus L.) powder and its application in emulsion-type sausage. LWT - Food Science and Technology, 64 (1), 74–81. doi: https://doi.org/10.1016/j.lwt.2015.05.030

- Font-i-Furnols, M., Guerrero, L. (2014). Consumer preference, behavior and perception about meat and meat products: An overview. Meat Science, 98 (3), 361–371. doi: https://doi.org/10.1016/j.meatsci.2014.06.025

- Veiga, C. P. da, Moreira, M. N. B., Veiga, C. R. P. da, Souza, A., Su, Z. (2023). Consumer Behavior Concerning Meat Consumption: Evidence from Brazil. Foods, 12 (1), 188. doi: https://doi.org/10.3390/foods12010188

- Alarcón-García, M. A., Perez-Alvarez, J. A., López-Vargas, J. H., Pagán-Moreno, M. J. (2020). Meat Snacks Consumption: Aspects That the Consumer Looks for to Consider Them a Healthy Food. The 1st International Electronic Conference on Food Science and Functional Foods. doi: https://doi.org/10.3390/foods_2020-07738

- Romeo-Arroyo, E., Mora, M., Vázquez-Araújo, L. (2020). Consumer behavior in confinement times: Food choice and cooking attitudes in Spain. International Journal of Gastronomy and Food Science, 21, 100226. doi: https://doi.org/10.1016/j.ijgfs.2020.100226

- Zahorulko, A. M., Zahorulko, O. Ye. (2021). Pat. No. 149981 UA. Plivkopodibnyi rezystyvnyi elektronahrivach vyprominiuvalnoho typu. No. u202102839; declareted: 28.05.2021; published: 23.12.2021, Bul. No. 51. Available at: https://base.uipv.org/searchINV/search.php?action=viewdetails&IdClaim=279791

- Babanov, I., Mikhaylov, V., Shevchenko, A., Mikhaylova, S. (2018). Perspective of roasting method of culinary products with electro-contact heat treatment. Processes of Food Industries, 23, 60–66. doi: https://doi.org/10.24263/2225-2916-2018-23-11

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Andrii Zahorulko, Aleksey Zagorulko, Nataliia Savytska, Sofiia Minenko, Andrii Pugach, Nataliia Ponomarenko, Ruslan Zakharchenko, Oksana Pikula

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.