Optimization of melon preservation technology using texture stabilizers and antioxidants

DOI:

https://doi.org/10.15587/1729-4061.2025.323610Keywords:

sterilization parameters, sensory quality, influence of pectin and calcium chloride, optimization of heat treatment, organoleptic properties, antioxidants, pectin, packagingAbstract

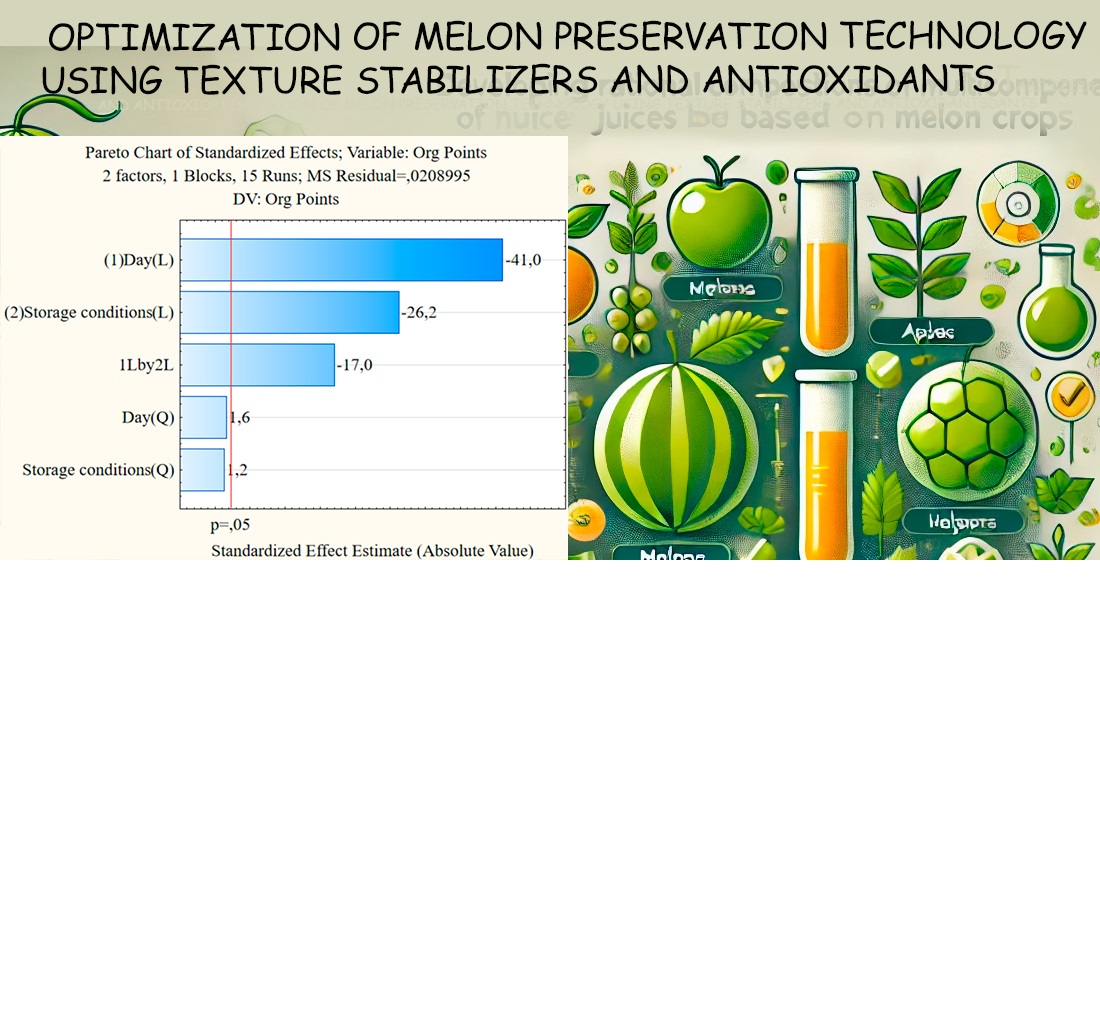

The object of this study is the technology of canning melon using texture stabilizers and antioxidants. The task is to preserve the organoleptic and physicochemical characteristics of the melon during canning and storage. Conventional processing methods lead to the loss of texture, aroma, and color, which reduces the consumer properties of the product.

The subject of the study is the effect of the concentration of calcium chloride, pectin, and blackcurrant extract on the textural, taste, and physicochemical properties of canned melon under various heat treatment modes and storage conditions. This paper discusses the optimization of melon canning technology aimed at improving its organoleptic and physicochemical properties. The effect of the concentration of calcium chloride, pectin, and blackcurrant extract on the texture, taste, and stability of the product during storage has been investigated.

Optimal parameters for canning melon, including stabilizer concentrations (1.25 % CaCl2, 1.0 % pectin) and heat treatment mode (70 °C, 20 minutes) have been defined.

It has been established that the combination of calcium chloride and pectin helps preserve the texture and improve the consistency of melon during long-term storage.

It has been revealed that the antioxidant properties of blackcurrant extract help preserve the color and taste of the canned product.

It has been determined that the optimal storage temperature is 4 °C, at which the product retains its characteristics for a year, while at room temperature the shelf life is reduced to 9 months.

The results could be used in the food industry for the production of canned melon with improved characteristics. Optimal parameters are especially relevant for storage in high temperatures in the south of Kazakhstan

References

- Food and Agriculture Organization of the United Nations. Available at: https://openknowledge.fao.org/server/api/core/bitstreams/28cfd24e-81a9-4ebc-b2b5-4095fe5b1dab/content/cc8166en.html

- Oms-Oliu, G., Soliva-Fortuny, R., Martín-Belloso, O. (2006). Effect of ripeness on the shelf-life of fresh-cut melon preserved by modified atmosphere packaging. European Food Research and Technology, 225 (3-4), 301–311. https://doi.org/10.1007/s00217-006-0415-9

- Alimardanova, M., Tlevlessova, D., Petrenko, E., Brindyukova, A. (2023). Development of technology for the production of sweet products based on melon fruit. ScienceRise, 1, 48–54. https://doi.org/10.21303/2313-8416.2023.002871

- Pan, X., Zhang, W., Lao, F., Mi, R., Liao, X., Luo, D., Wu, J. (2021). Isolation and identification of putative precursors of the volatile sulfur compounds and their inhibition methods in heat-sterilized melon juices. Food Chemistry, 343, 128459. https://doi.org/10.1016/j.foodchem.2020.128459

- Lieu, M. D., Dang, T. K. T., Nguyen, T. H. (2024). Green synthesized silver nanoparticles, a sustainable approach for fruit and vegetable preservation: An overview. Food Chemistry: X, 23, 101664. https://doi.org/10.1016/j.fochx.2024.101664

- Jin, Y. Z., Lv, D. Q., Liu, W. W., Qi, H. Y., Bai, X. H. (2013). Ethanol vapor treatment maintains postharvest storage quality and inhibits internal ethylene biosynthesis during storage of oriental sweet melons. Postharvest Biology and Technology, 86, 372–380. https://doi.org/10.1016/j.postharvbio.2013.07.019

- Mosqueda-Melgar, J., Raybaudi-Massilia, R. M., Martín-Belloso, O. (2008). Combination of high-intensity pulsed electric fields with natural antimicrobials to inactivate pathogenic microorganisms and extend the shelf-life of melon and watermelon juices. Food Microbiology, 25 (3), 479–491. https://doi.org/10.1016/j.fm.2008.01.002

- Chen, J. luan, Zhang, J., Song, L., Jiang, Y., Wu, J., Hu, X. S. (2010). Changes in microorganism, enzyme, aroma of hami melon (Cucumis melo L.) juice treated with dense phase carbon dioxide and stored at 4 °C. Innovative Food Science & Emerging Technologies, 11 (4), 623–629. https://doi.org/10.1016/j.ifset.2010.05.008

- Ukuku, D. O., Bari, M. L., Kawamoto, S., Isshiki, K. (2005). Use of hydrogen peroxide in combination with nisin, sodium lactate and citric acid for reducing transfer of bacterial pathogens from whole melon surfaces to fresh-cut pieces. International Journal of Food Microbiology, 104 (2), 225–233. https://doi.org/10.1016/j.ijfoodmicro.2005.01.016

- Yerenova, B., Tlevlessova, D., Almaganbetova, A., Almasbek, A. (2024). Development of rational compositions for multicomponent juices based on melon crops. Technology and Equipment of Food Production, 4 (11 (130)), 87–98. https://doi.org/10.15587/1729-4061.2024.310327

- Uikassova, Z., Azimova, S., Tlevlessova, D., Galoburda, R. (2022). Determining critical control points for processing melon fruits. Eastern-European Journal of Enterprise Technologies, 4 (11 (118)), 97–104. https://doi.org/10.15587/1729-4061.2022.262850

- Oms-Oliu, G., Raybaudi-Massilia Martínez, R. M., Soliva-Fortuny, R., Martín-Belloso, O. (2008). Effect of superatmospheric and low oxygen modified atmospheres on shelf-life extension of fresh-cut melon. Food Control, 19 (2), 191–199. https://doi.org/10.1016/j.foodcont.2007.03.009

- Alimardanova, M., Tlevlessova, D., Syzdykova, L., Karlygash, A., Petrenko, Y., & Brindyukova, A. (2023). Trends in the development of the processing of melons and gourds. ScienceRise, (1), 35-47. https://doi.org/10.1016/j.foodcont.2007.03.009

- Yerenova, B., Medvedkov, Y., Tlevlessova, D., Kairbayeva, A. (2022). Resource-saving melon processing technology. EUREKA: Life Sciences, 4, 54–75. https://doi.org/10.21303/2504-5695.2022.002636

- Brindyukova, A., Yerenova, B., Syzdykova, L., Abdiyeva, K., Tlevlessova, D. (2023). Development of technology for the production of useful jelly candies from cucurbit crops on a natural basis. Eastern-European Journal of Enterprise Technologies, 3 (11 (123)), 60–67. https://doi.org/10.15587/1729-4061.2023.282061

- Ginés-Ariza, P., Fusté-Forné, F., Noguer-Juncà, E. (2022). Valorising the rural pantry: Bridges between the preservation of fruits and slow tourism in Catalonia. Journal of Agriculture and Food Research, 10, 100386. https://doi.org/10.1016/j.jafr.2022.100386

- Prakash, B., Gautam, I. P. (2014). Participatory Evaluation of True Potato Seed (F1C2 Tuberlets) for Potato Production at Kabhrepalanchok district, Mid Hills of Nepal. JOURNAL of Horticulture, Forestry and Biotechnology, 18 (3), 1–7.

- Bett‐Garber, K. L., Greene, J. L., Lamikanra, O., Ingram, D. A., Watson, M. A. (2011). Effect of storage temperature variations on sensory quality of fresh‐cut cantaloupe melon. Journal of Food Quality, 34 (1), 19–29. https://doi.org/10.1111/j.1745-4557.2010.00362.x

- Liu, Y., Hu, X., Zhao, X., Song, H. (2012). Combined effect of high pressure carbon dioxide and mild heat treatment on overall quality parameters of watermelon juice. Innovative Food Science & Emerging Technologies, 13, 112–119. https://doi.org/10.1016/j.ifset.2011.11.001

- Wu, Z., Tu, M., Yang, X., Xu, J., Yu, Z. (2020). Effect of cutting and storage temperature on sucrose and organic acids metabolism in postharvest melon fruit. Postharvest Biology and Technology, 161, 111081. https://doi.org/10.1016/j.postharvbio.2019.111081

- Wen, X., Hu, R., Zhao, J., Peng, Y., Ni, Y. (2015). Evaluation of the effects of different thawing methods on texture, colour and ascorbic acid retention of frozen hami melon (Cucumis melo var. saccharinus). International Journal of Food Science & Technology, 50 (5), 1116–1122. https://doi.org/10.1111/ijfs.12755

- Jain, V., Chawla, S., Choudhary, P., Jain, S. (2019). Post-harvest calcium chloride treatments influence fruit firmness, cell wall components and cell wall hydrolyzing enzymes of Ber (Ziziphus mauritiana Lamk.) fruits during storage. Journal of Food Science and Technology, 56 (10), 4535–4542. https://doi.org/10.1007/s13197-019-03934-z z

- Manganaris, G. A., Vasilakakis, M., Diamantidis, G., Mignani, I. (2005). Effect of calcium additives on physicochemical aspects of cell wall pectin and sensory attributes of canned peach (Prunus persica (L) Batsch cv Andross). Journal of the Science of Food and Agriculture, 85 (10), 1773–1778. https://doi.org/10.1002/jsfa.2182

- Ansah, F. A., Amodio, M. L., Colelli, G. (2018). Quality of fresh‐cut products as affected by harvest and postharvest operations. Journal of the Science of Food and Agriculture, 98 (10), 3614–3626. https://doi.org/10.1002/jsfa.8885

- Ma, L., Zhang, M., Bhandari, B., Gao, Z. (2017). Recent developments in novel shelf life extension technologies of fresh-cut fruits and vegetables. Trends in Food Science & Technology, 64, 23–38. https://doi.org/10.1016/j.tifs.2017.03.005

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Dinara Tlevlessova, Laila Syzdykova, Karlygash Abdiyeva, Madina Kozhakhiyeva, Aliya Yessengaziyeva, Rauza Sabit, Aigerim Bisengalieva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.