Investigating the effect of corn silk extract on the properties of the traditional fermented dairy product ayran

DOI:

https://doi.org/10.15587/1729-4061.2025.335174Keywords:

corn silk, ultrasonic extraction, aqueous extract, amino acid profile, antioxidant activityAbstract

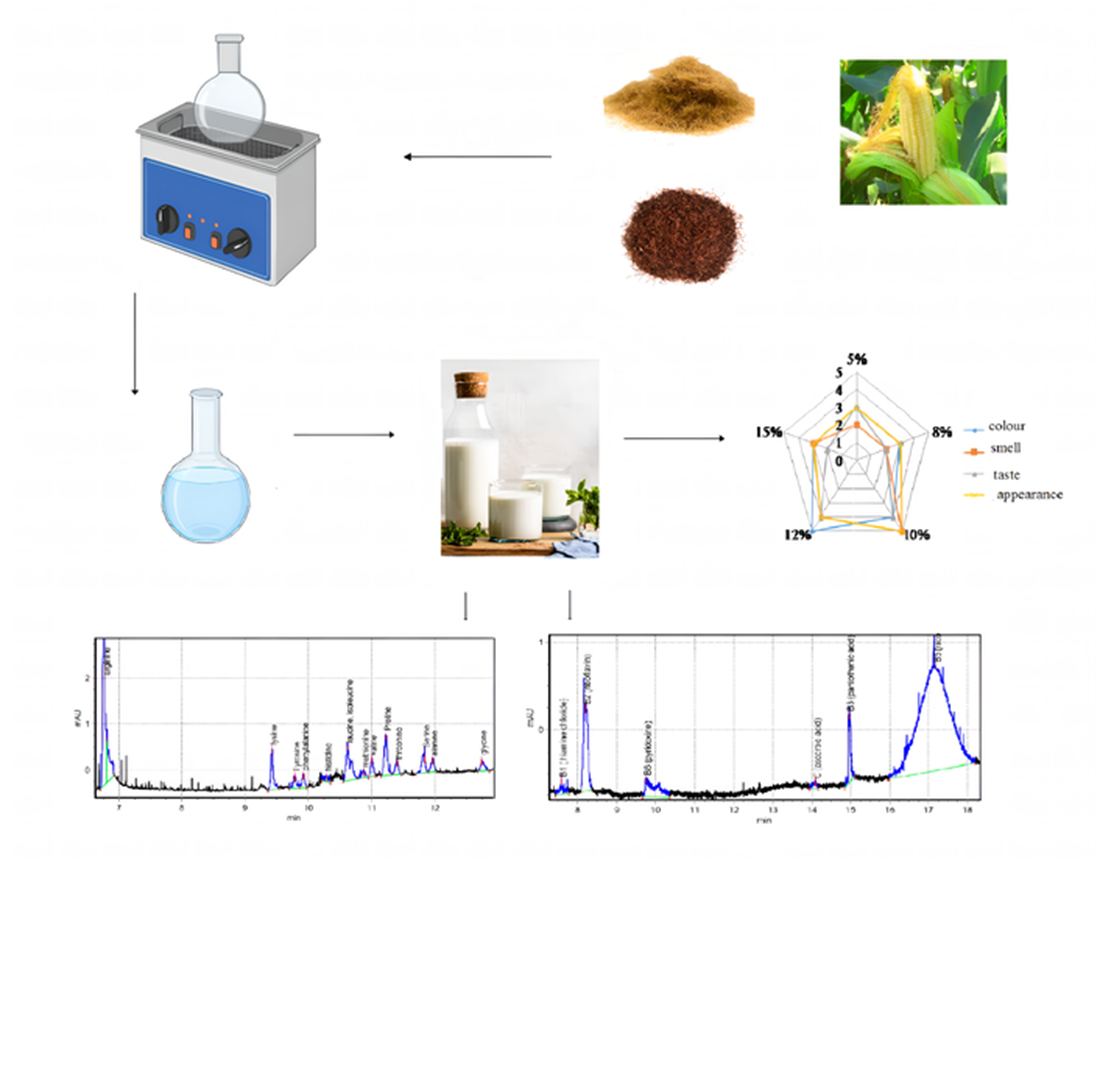

This study's object is the potential of fresh and dried corn silk (CS) as functional ingredients for fortifying the national fermented milk product – ayran.

There is an obvious need for comprehensive research into fermented products based on plant-milk synergy. The current study is aimed at solving the task of increasing the nutritional value of ayran by fortifying it with extracts from local raw materials.

A series of comprehensive studies were conducted to reveal the potential of fermented ayran products with CS extracts using the synergistic effect of plant and dairy matrices. A technology for ayran fortified with biologically active compounds of CS extract has been devised. It has been established that under the influence of CS extract, the content of polyphenols and flavonoids increases by 22.2%, which accompanies the antioxidant activity of corn silk in products. In the experimental sample, a significant increase (by 10.49%) in protein content was observed, which exceeds the control value. This activation led to the conclusion that corn silk significantly improves the amino acid profile of the product. The concentration of some amino acids increased significantly. The most pronounced increase is observed for proline (by 18.28%), methionine (by 15.67%), valine (by 13.36%), arginine (by 13%), and tyrosine (by 12.7%). An increase in the level of phenylalanine (by 10%), histidine (by 6.47%), alanine (by 6.7%), serine (by 4.9%), glycine (by 3.8%), lysine (by 2.1%), and isoleucine with leucine (by 0.98%) was also noted. Ayran with aqueous extract of corn silk demonstrated an improved mineral profile. The contents of important minerals such as sodium (4.77%), magnesium (1.21%), phosphorus (10.90%), potassium (18.08%), calcium (10.68%), chlorine (11.25%), and sulfur (0.71%) increased significantly. These changes indicate that the designed product could be considered an improved functional food and with the potential for commercialization

References

- Konuspayeva, G., Baubekova, A., Akhmetsadykova, S., Faye, B. (2023). Traditional dairy fermented products in Central Asia. International Dairy Journal, 137, 105514. https://doi.org/10.1016/j.idairyj.2022.105514

- Zhadyra, S., Han, X., Anapiyayev, B. B., Tao, F., Xu, P. (2021). Bacterial diversity analysis in Kazakh fermented milks Shubat and Ayran by combining culture-dependent and culture-independent methods. LWT, 141, 110877. https://doi.org/10.1016/j.lwt.2021.110877

- Kalabaevna, A. M., Aybergen, A. (2023). Pischevaya tsennost', aminokislotniy, zhirnokislotniy sostav napitka «koyyrtpak» s rastitel'nymi dobavkami, pokazateley kachestva. Theoretical Hypotheses and Empirical Results, 3. Available at: https://ojs.scipub.de/index.php/THIR/article/view/1582

- Yarmagametova, B. A., Kizatova, M. Zh. (2021). Current state of technology for obtaining extract from corn germ (zea mays germinis). Farmaciâ Kazahstana, 2, 79–83. https://doi.org/10.53511/pharmkaz.2021.31.72.021

- Daud, N. M., Putra, N. R., Jamaludin, R., Md Norodin, N. S., Sarkawi, N. S., Hamzah, M. H. S. et al. (2022). Valorisation of plant seed as natural bioactive compounds by various extraction methods: A review. Trends in Food Science & Technology, 119, 201–214. https://doi.org/10.1016/j.tifs.2021.12.010

- Tadeo, J. L., Sánchez-Brunete, C., Albero, B., García-Valcárcel, A. I. (2010). Application of ultrasound-assisted extraction to the determination of contaminants in food and soil samples. Journal of Chromatography A, 1217 (16), 2415–2440. https://doi.org/10.1016/j.chroma.2009.11.066

- Yusoff, I. M., Mat Taher, Z., Rahmat, Z., Chua, L. S. (2022). A review of ultrasound-assisted extraction for plant bioactive compounds: Phenolics, flavonoids, thymols, saponins and proteins. Food Research International, 157, 111268. https://doi.org/10.1016/j.foodres.2022.111268

- Flores-Sauceda, M., Othón-Díaz, E. D., Fimbres-García, J. O., Cruz-Valenzuela, M. R., Silva-Espinoza, B. A., Vazquez-Armenta, F. J. et al. (2025). Corn silk-derived bioactives as polyphenol oxidase inhibitors: Mechanisms and applications in food preservation. Food Bioscience, 68, 106411. https://doi.org/10.1016/j.fbio.2025.106411

- Tian, S., Sun, Y., Chen, Z. (2021). Extraction of Flavonoids from Corn Silk and Biological Activities In Vitro. Journal of Food Quality, 2021, 1–9. https://doi.org/10.1155/2021/7390425

- Sarepoua, E., Tangwongchai, R., Suriharn, B., Lertrat, K. (2015). Influence of variety and harvest maturity on phytochemical content in corn silk. Food Chemistry, 169, 424–429. https://doi.org/10.1016/j.foodchem.2014.07.136

- Kizatova, M. E., Sultanova, M. Zh. (2021). Obzor sposoba ekstraktsii, kak effektivnogo metoda analiza. In The XV International Science Conference «Trends in the development of science and practice». Madrid, 384–389.

- Aitbayeva, A. Zh., Alibekov, R. S., Farah, S. T. (2023). The research of secondary resources in corn processing. The Journal of Almaty Technological University, 2, 29–37. https://doi.org/10.48184/2304-568x-2023-2-29-37

- Liu, J., Wang, C., Wang, Z., Zhang, C., Lu, S., Liu, J. (2011). The antioxidant and free-radical scavenging activities of extract and fractions from corn silk (Zea mays L.) and related flavone glycosides. Food Chemistry, 126 (1), 261–269. https://doi.org/10.1016/j.foodchem.2010.11.014

- Utebaeva, A., Gabrilyants, E., Abish, Z. (2024). Developing a Symbiotic Fermented Milk Product with Microwave-Treated Hawthorn Extract. Fermentation, 10 (8), 377. https://doi.org/10.3390/fermentation10080377

- Akgün, D., Gültekin-Özgüven, M., Yücetepe, A., Altin, G., Gibis, M., Weiss, J., Özçelik, B. (2020). Stirred-type yoghurt incorporated with sour cherry extract in chitosan-coated liposomes. Food Hydrocolloids, 101, 105532. https://doi.org/10.1016/j.foodhyd.2019.105532

- Patel, S., Goyal, A. (2012). The current trends and future perspectives of prebiotics research: a review. 3 Biotech, 2 (2), 115–125. https://doi.org/10.1007/s13205-012-0044-x

- Kizatova, M., Tashpolatova, S. (2023). Study of the chemical composition and pharmacological action of corn columns with silks. Scientific Collection "InterConf", 140, 537–543. Available at: https://archive.interconf.center/index.php/conference-proceeding/article/view/2232

- Utebaeva, A., Yevlash, V., Gabrilyants, E., Abish, Z., Aitbayeva, A. (2024). Development of kefir product with Bifidobacterium animalis subsp. lactis (BB-12) activated by Sanguisorba officinalis L. extract. Eastern-European Journal of Enterprise Technologies, 5 (11 (131)), 6–15. https://doi.org/10.15587/1729-4061.2024.312708

- Tastemirova, U. U., Mukhtarkhanova, R. B., Singisov, A. U. (2023). Study of the yield of dry substances during extraction of grape seeds and flax seeds. The Journal of Almaty Technological University, 4, 174–181. https://doi.org/10.48184/2304-568x-2023-4-174-181

- Muda, R. J., Nurhanan, A. R., Rosli, W., Mohsin, S. (2012). Total polyphenol content and free radical scavenging activity of cornsilk (Zea mays hairs). Sains Malaysiana, 41 (10), 1217–1221. Available at: https://www.researchgate.net/publication/285794785_Total_Polyphenol_Content_and_Free_Radical_Scavenging_Activity_of_Cornsilk_Zea_mays_hairs

- Alibekov, R. S., Aitbayeva, A. Z., Khamitova, B. M., Azimov, A. M., Sulaiman, A., Mustapa Kamal, S. M., Taip, F. S. (2025). Effects of maltodextrin in freeze drying on the physical and functional properties of different type of milk powder. Cogent Food & Agriculture, 11 (1). https://doi.org/10.1080/23311932.2025.2473540

- Krekker, L. G., Kolosova, E. V. (2022). Antioxidant activity as a functional advantage of a fermented milk product during storage. Storage and processing of agricultural raw materials, 2, 147–160. https://doi.org/10.36107/10.36107/spfp.2022.348

- Rahmani, F., Gandomi, H., Noori, N., Faraki, A., Farzaneh, M. (2021). Microbial, physiochemical and functional properties of probiotic yogurt containing Lactobacillus acidophilus and Bifidobacterium bifidum enriched by green tea aqueous extract. Food Science & Nutrition, 9 (10), 5536–5545. https://doi.org/10.1002/fsn3.2512

- Al-Hindi, R. R., Abd El Ghani, S. (2020). Production of Functional Fermented Milk Beverages Supplemented with Pomegranate Peel Extract and Probiotic Lactic Acid Bacteria. Journal of Food Quality, 2020, 1–9. https://doi.org/10.1155/2020/4710273

- Stobiecka, M., Król, J., Brodziak, A. (2022). Antioxidant Activity of Milk and Dairy Products. Animals, 12 (3), 245. https://doi.org/10.3390/ani12030245

- Tastemirova, U., Mukhtarkhanova, R., Shingisov, A., Yevlash, V. (2023). Identifying of the effect of the combined extract on the quality indicators of a fermented milk product from reconstituted camel milk. Eastern-European Journal of Enterprise Technologies, 6 (11 (126)), 51–58. https://doi.org/10.15587/1729-4061.2023.294930

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Aigerim Aitbayeva, Makhabat Kassymova, Maigul Kizatova, Ravshanbek Alibekov, Aidana Utebaeva

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.